@traspino

- Followers 0

- Following 0

- Updates 206

Blog

There are many who ask blow molding vs injection molding, what are the differences?

There are two commonly used types of plastic manufacturing processes, blow molding and injection molding. Each have their own applications and procedures. Knowing what sets them apart can help you decide which one is the most suitable for your project.

Differences Between Blow Molding and Injection Molding

Blow Molding is a process where hot plastic is expanded into a mold to create hollow objects, like bottles and containers, Plastic Injection Molding , on the other hand, is a process where molten plastic is forced into a mold and cured to create solid shapes, such as party favors and plastic spoons.

Which One Should You Choose for Your Project

When choosing between Blow Molding vs Injection Molding for your project, you should take a moment to think about the product that you want to create. If you require a hollow structure, such as a bottle or container, Blow Molding is more than likely the process for you. But if you require density, a solid object like a toy or kitchen accessory, Injection Molding can be a better option.

A Comprehensive Comparison

Blow Molding vs ABS Injection Molding Comparison Both these processes do not produce same types of shapes and are relatively different when it comes to the method and material used, production speed, production cost, sizes and designs. Blow Molding tends to be faster and less expensive for high volumes of hollow shapes. On the other end of the spectrum, Injection Molding is used to produce solid shapes in small to moderate production runs.

Factors to Consider

There are a couple of considerations when determining Blow Molding or so need Injection Molding. The complexity of your product, the size of your project, your production timeline, and your budget are all factors that will influence what method is best for you. You also want to take into account the construction material; some plastics are better for Blow Molding, and others are better for Injection Molding.

Both Blow Molding and High Precision Injection Molding have their strengths and weaknesses; the trick is to analyze if it applies to your specific product. Understanding these differences and weighing various factors such as the type of product, amount, budget and material, you should be able to decide which method best suits your project. If you want more help in selecting the right process fail to hesitate to let us know!Shanghai Ruimin Moldplastic Technology can also help! We are expert in plastics production and we will be able to help you all the way to achieve your successful project. Get in touch with us now to find out more about how we can help you bring your plastic product to life.

One SKU, Three Box Sizes 7 Diffuse LED Modules Southeast Asia Installers Stock for Fast ROI

By traspino, 2025-08-07

Hey there, young readers! So, party people, you know, today just, we’re gonna talk about some cool stuff that is going to help make your life a little bit easier as an installer in the depths of Southeast Asia. Our friends at Laili came up with a clever idea, they offer three box sizes for LED Modules and one product called an SKU.

Simplify Inventory Flow with One SKU

Imagine trying to manage all sorts of things in order to do your work. It can be difficult and time consuming. But with Laili’s one SKU for all of their Backlit poster no-shadow diffuse LED module modules, installers are able to seriously cut down on their inventory requirements. Just pick up the appropriate box size for the task and off you go.

Improve efficiency with diffuse LED modules for installation in Southeast Asia

Now, while we’re here, let’s address something known as Single-color diffuse LED strip for light box modules. Those are super cool, because they diffuse light everywhere, and that can be super helpful in different lighting situations. Installers in Southeast Asia are going to love working with these modules because they offer the opportunity to feature well-lit and inviting spaces with no harsh shadows.

Fill your stock with multi-use LED modules to achieve faster ROI in Southeast Asia

And ROI is short for Return on Investment, which is to get back more than you put in. Installers in Southeast Asia who buy upping on Laili’s adaptable and flexible lighting modules set to boost their ROI. Not only are these modules efficient, but they also are long lasting aiding in saving more money over time.

Ready-to-Use LED Modules of Different Sizes for Easy Installation

A good fit matters when you're installing LED modules. Laili’s LED modules come in several sizes so that installers can get the prefect fit on the job. There is cutting or measuring required on your end it is only a matter of selecting the right size and installing.

Grow Profits Faster with Southeast Asia Termination Installers’ Go-To LED Modules

Finally, what about profitability? Well, every installer wants to make a profit, no? Since installers in South-East Asia are able to speed up their earnings by using Laili’s LED modules. These modules are dependable and high performing, allowing installers to deliver excellent service to their customers and differentiate themselves in the market.

Well then, ‘Cuse readers, you heard it yourself, with Laili’s single SKU, triple box sizes, and modular whisky, you are king of the hill, top of the heap, and toast of the town, in Southeast Asia. Keeping a stock of such improve and ready-to-use modules can allow the installers to be more efficient during their work and accelerate the profitabilty. How awesome is that? It’s kind of like a magic tool that makes everything so much easier and more fun.

So, next time you come across Laili’s Monochrome diffuse LED bar for ceiling soft film , think of how they are enabling installers throughout South East Asia to effortlessly brighten up their spaces in style. You never know and maybe one day you are going to develop an installer that supports these fantastic modules when you build your own projects. Until then, keep exploring and learning there’s a world full of cool and inventive ideas out there, just waiting for you to find them.

Secant Pile Construction Basics Explained

Transmix walls are barrier walls constructed in the ground to support excavation for a building, a bridge or other structure. The walls are constructed from interlocking concrete piles, which are staggered next to each other to prevent soil falling into the excavation.

How Secant Piles Are Constructed Here is a step by step break down of secant pile construction.

The first operation in the construction of a secant pile shoring is to drill holes in the ground for the piles to be sunk. Stell reinforcement is place in the holes and concrete is poured in the hole after the holes are drilled. Once concrete hardens, the piles are structurally molded into a strong wall of walls.

Investigation on Equipment and Method of Secant Pile Construction

Drilling rigs, casings and concrete pumps are equipment and methods applied in secant pile construction. The holes for the piles are made using drilling rigs; casings support the holes as they are drilled. Concrete Pumps are then used to inject the holes with concrete to make the piles strong and secure.

Confronting Obstacles in the Construction of Secant Piles

Challenges for the construction of secant pile retaining wall are, for example, adverse soil conditions or limited space on site. In order to address these issues, the construction process needs to be well-thought out and correct equipment and methods need to be used. You should always just rely on professionals like those from KIMDRILL to help you to make the project a reality without any hindrances.

Tips and Tricks for Beginners

To any novice eager to get more information on secant pile construction; you should first start by getting acquitted with the fundamentals of the process. Investigate the various types of equipment and methods for secant pile construction and consult secant pile specialists for advice and assistance. Just like learning a new language, the more you practice, the better you become, so rolling up your sleeves and getting involved with secant pile construction is an invaluable lesson.

In short, secant pile foundation is a complicated, though critical process, in the development of strong and sturdy foundation walls. Through reading a step by step program, an exposure to the various tools and techniques and a mentorship to help troubleshoot and strategize, beginners can become pros at finishing their secant pile construction projects. So with patience and practice, everyone can become an expert in construction of secant pile walls, and do their part in making the future more beautiful.

Detailers are those people who help keep cars shined and clean. Occasionally, they need special tools to make it happen. One of the tools the detailers commonly employ is steel wool or scuff pads. But there is something that has recently changed 83% of detailers who have switched from scuff pads and now use steel wool say they will never go back!

Steel wool and scuff pads are used to clean and polish cars, but detailers have been finding steel wool is better. Let’s dig into the reasons behind the shift from steel wool to scuff pads and look at why detailers everywhere are choosing steel wool.

Here are the reasons 83 percent of detailers made the transition to both.

Steel Wool is More Durable Another reason why steel wool or buff pads for car is being preferred to scuff pads by detailers is because steel wool is more hard-wearing. This makes it last longer than it can be used on a number of cars until it wears itself out. Detailers do not have to keep replacing steel wool like they do with scuff pads, which saves them both time and money in the long-term.

Detailers are also reaching for steel wool for another reason: The product is versatile. Steel wool can be utilized for a host of applications, from knocking back a good stain to lustrous chrome steel. Scuff pads, however, have limited uses and may be less effective in some instances.

Why detailers are giving scuff pads the boot for good:

Detailers find that it provides easier scuffing then scuff pads. Steel wool can clean off dirt & grime faster and easier, helping the detailing process go faster and be more efficient. Which it did in less time than when not IF (by comparison to not using it, it does do, in only slightly less time now than it would using steel wool, which is “good” for the busy detailer).

Furthermore, detailers are even finding that steel wool leaves a slicker finish than scuff pads. When steel wool is used, surfaces are left in a sleek, glossy, polished condition; no roughness or unevenness arises. This is significant for auto detailing and similar tasks, where the aim is to make vehicles appear like new.

Revealing the advantages of using steel wool in auto detailing:

You also have several good reasons to consider using steel wool and buffing pads as a detailer. Steel wool is tough and adaptable aside from being efficient, and providing a cleaner finish, steel wool is also gentle on the surfaces. Detailers can use this steel wool with confidence and not worry about scratching or harming the cars they are detailing.

In addition, steel wool is simple to use and simple to wash. Steel wool makes a great tool for detailers. It enables detailers work on various tasks and keep their tools looking like new. This convenience is another is another reason that detailers are reluctant to give up on steel wool.

Whyy crazy detailers still use steel wool:

Detailers are often shocked by the success they get with steel wool. Numerous detailers have said steel wool provided a level of workmanship they had not believed they were capable of, and made the job much easier to do. They can do better work faster, which is a win-win to detailers and the clients they serve.

The reasons most detailers are opting steel wool and sanding pads over scuff pads in general is they have them, steel wool is gonna last a lot longer so its more cost effective, they can be used for many other things, they work faster, they produce a shinier finish, they are more forgiving, and they are easier to use. Product Description Detailing Steel Wool: Shanghai Abrasive Tools Co., LTD supply "New" steel wool for the cleaning and finishing In detaling process. So for you detailers out there curious about making the switch, the next time you have to polish a car try some steel wool for automotive detailing rather than the old method you're used to and you won't be disappointed.

S31803 vs S32205: Choosing the Right Duplex Fastener for Chemical Processing Plants

By traspino, 2025-08-07

Differences between S31803 and S32205 duplex fasteners explained

Chemical processing plants depend on duplex fasteners. They’re applied to keep various parts and equipment together to ensure that none of them gets out of place, lest something goes wrong in that area. If you’re considering a duplex fastener for your plant then knowing the differences between S31803 and S32205 is a good idea.

S31803 and S32205 are standard duplex stainless steel. They are a kind of duplex stainless steel, which are c composed of approximate equal amounts of ferrite and austenite. Yet, they have certain differences which can affect their performance in chemical processesnistanical.

S31803 is an austenitic-ferritic stainless steel with 22% chromium, 5-6% nickel, and 3% molybdenum. It exhibits excellent corrosion resistance, high strength, and ease of fabrication, making it a widely-used material in applications where the property requirements are not very demanding. On the contrary, S32205 features slightly higher contents of Cr, Ni and Mo in the duplex bolts stainless steel, which may lead to its better corrosion resistance.

Things to consider when choosing the best duplex fastener for chemical processing plants

There are a few different factors to evaluate when deciding between S31803 and S32205 duplex fasteners for your chemical processing plant. There are a few key considerations, the first being the type of chemicals your plant is handling. Not all chemicals are equally corrosive, so it is important to choose a duplex fastener that can handle the actual chemical environment.

Another thing to think about is the temperature and pressure levels in your plant. So, the duplex fasteners are required to work under intense temperatures and pressures and yet, retain its strength and corrosion resistance quality. Further, duplex fasteners are affected by vibration, stress and seawater concentration.

The criticality of corrosion resistant duplex fasteners in chemical processing

Corrosion is the one of the biggest problems in a chemical processing industry leading to failur of equipment and leaks and some time such leaks can be very dangerous to human life. High corrosion-resistant duplex fasteners are a must to provide long term service and longevity to your plant’s equipment.

S31803 and S32205 super duplex bolts are highly resistant to corrosion and are 6O% ferritic and 4O% austenitic. Yet, S32205 has better general corrosion resistance in a variety of environments than 316 because of its higher content of chromium, nitrogen, and molybdenum. Selecting the appropriate duplex fasteners which are highly corrosion resistant is an effective way to mitigate expensive downtime and labor in your facility.

Mechanical Properties Comparison between S31803 and S32205 duplex fasteners

Among mechanical properties, not only the corrosion behaviour but also the strength is significant when designing duplex fasteners. S31803 and S32205 duplex fasteners are generally known for their excellent resistance to stress corrosion cracking and their high strength combined with excellent ductility and impact strength.

S32205, however, normally has more increased tensile and yield strength than S31803 and is also widely used for the same purposes where higher mechanical performance is required. Knowing how the two duplex fasteners differ in their mechanical properties can assist you in choosing a fastener that is right for your plant.

How to Choose the Best Duplex Fasteners for Your Chemical Processing Requirements

In order to select the right duplex fastener for your particular chemical processing application, take into account your plant’s operating environment, the chemicals you will be processing, and the mechanical specs of your application. By consulting with a trusted supplier such as JM Hardware, you can make sure you get the right duplex fastener for the needs of your plant.

You can now from our broad range of quality duplex fasteners which includes both S31803 and S32205 to suite the varied chemical processing needs. Our engineering team has the expertise to help you choose the best duplex 2205 bolts for your plant, it will help you to ensure the best up-time while maintaining high productivity of your plant. With the appropriate duplex fastener, you can improve the productivity and safety of your chemical processing facility for decades to come.

2025 Interior Trends: How Decorative Mirror Stickers Are Transforming Retail & Hospitality Spaces

By traspino, 2025-08-06

Decorative like stickers are all the rage in interior design and the retail/hospitality space is changing because of them. These stickers are a form of magic they take the simplest room and with just the tiniest peel-and-stick, create this larger-than-life, brighter-than-the-sun statement.

Decorative Mirror Stickers are the New Trend in Interior Design

They come in may shapes and sizes, from circles to tessellation patterns. Everyone loves them because they are inexpensive, easy to do and can make such a huge impact in a room within minutes. Mirror Sticker can provide the illusion of a larger place, give an element of glamour or even create a statement with sparkly mirrored stickers centrally placed.

Mirror Stickers Are The Latest Trend To Transform Retail And Hospitality Interiors

Mirror stickers are a great thing to have in many retail or hospitality spaces. With a design as intricate as this one, these stickers can be used to create an astonishing focal point within business premises, hotel lobbies or shop entrance and even with restaurant renovations. These mirror stickers enable businesses to make budget-friendly updates to their spaces. And mirror stickers are a favourite of customers, as they give their spaces a modern and stylish vibe.

How Mirror Stickers Have Rendered ChangesOver Design Trends

Singh says that mirror stickers are not only a trend but also will continue to flourish. SourceDesigners and decorators are constantly scrounging up new ideas for incorporating mirror stickers in their projects. Mirror stickers are even suitable for a bohemian chic space, or a Scandinavian interior. They are of many types, can be easily customized, and you can remove them without causing any damage to the walls or surfaces. The design options are truly limitlessheres a great example of turning your cupboard doors into mirrors using mirror stickers

Mirror Stickers Take Center Stage

Whereas mirror sticker decor were once that little something extra, they are now parading the spotlight for interior design. From a full wall of mirrored tiles in a high-end boutique shop, to a quirky mirror sticker installation the atrium of a hotel -these stickers make their mark. They can create a sense of scale, add visual weight, or just turn on the lights. From ordinary room to work of art, with mirror stickers

The luxury of Mirror Stickers for Retail & Hospitality

Shops and accommodation as well should probably consider mirror stickers in their places at this moment if you own it.. These stickers areA cost effective way to elevate your space, draw in customers, and scorch a memory on any guest at your venue! Indulge in mirror stickers for walls, doors or even ceilings and furniture to include a little edge. No matter what look you wish to achieve, mirror stickers allow you to create a custom design.

Mirror stickers are a unique and trendy way to revamp any retail store, resume store, or hospitality space! Featuring their versatile nature, cost-effectiveness and unique ability to shape design trends, it is no exaggeration that mirror stickers are a must-have for any business desiring to refresh their interiors. Get your Self adhesive mirror tiles today at Yongxin Reflective and remodel your space.

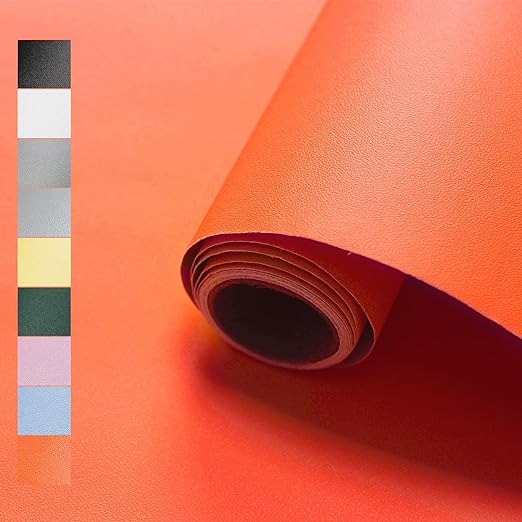

Textured vs Glossy PVC Decoration Films: Which Performs Better for Export-Quality Furniture?

By traspino, 2025-08-06

Textured PVC Decoration Films Vs Glossy PVF Decoration Films

The secret is found in the materials decorating it, like PVC decoration films. This type of films as the adhesive stickers fancy book sticker on wards closets that millions give stylish and diverse view. But do you know that there are various types of PVC decoration film and each type is unique from the rest? that how Textured PVC Decoration is different than glossy and which among them can be the better choice to export Quality Furniture.

Why Export-Quality Furniture Must Be Of Top-Quality Sourcing

Being produced as furniture for export, it has to hold up to the high quality standards that people expect all over the world. Here is where wood grain pvc decorative film play their role. These films not only enhances the beauty of furniture but also save it from scratches and damages. Check the quality of PVC Decoration film-The Right PVC decoration film plays a crucial part in providing you with export quality furniture that is top-grade and has an extensive life span to last for a longer period of time.

PVC decoration film | Compare durability with aesthetics.

These Textured PVC decoration films have a tough surface that looks like wonderful wooden, stone. These are amazing to use as faux furniture overlays which you can glue on. And glossy PVC decoration films are shiny and have a reflection of light on its surface, that your home furniture will look most modern & stick. Textured films are tougher and the texture can often hide scratches, while glossy film is easier to clean and may retain a reflective shine for longer.

Deciding right for optimum performance in furniture

The choice between textured and glossy PVC Decorative Film is mainly dependent on the needs of the furniture design and the preferred surface finish by end-users in a target market. Textured films are- if you are looking to create a natural and rustic vibe. Although, if you are aiming for a modern and classy look, so glossy wraps would be your thing. If you choose carefully, taking into account what kind of aesthetics and durability you are looking for when it comes to your furniture, you can create something individual to the rest and be sure that your pieces stand out enough so as they attract potential customers from around the world.

Production of export-quality furniture made more efficient with optimal PVC Decoration Film

PVC decoration film come in many forms, but with yongxin reflective you can trust that our PVC decoration films are available to purchase for use on export grade furniture. Our product is made out of either textured or glossy finishes, to make your furniture look more better and durable. Outstanding furniture in your factory optimized fast at a high production speed; Release Film if you find the perfect PVC decoration film. Yongxin Reflective is the best manufacturer you can trust to offer the PVC decoration films for export-quality furniture.

In a nutshell, while it may boil down to personal preferences, when selecting export-quality pvc self adhesive flooring for textured vs. smooth PVC both offer various advantages that make them ideal in different situations and finding the right one for your purpose is a good approach. As furniture is an investment, there are several factors to consider so that you make the right decision and enhance your furniture performance by targeting durability fits great on market preference. Yongxin barnd high quality PVC decoration films for all of your beautiful furniture that will be world costumes favorite.

Do you know some specific film exist to protect, maintain and earn for you more money when you're about to sell your car? It’s called PPF Film, and it’s like a superhero for your car’s exterior. We here at KPAL FILM just want to tell you about the advantages of PPF Film for your car.

The advantages of PPF film to protect your car from the outside

For a start, let's discuss how PPF Film can shield the exterior of your car. As you cruise around in your car, it can pick up scratches, dings and other damage from rocks, bugs and other items that are on the road. But let’s say if your car is already protected with PPF Film, which acts like an armor shield to absorb these impacts keeping your ride looking new.

How PPF saves the value of your vehicle

So now onto how ppf Film can protect the value of your car. If you do decide to sell your car down the line, prospective buyers will also appreciate a clean exterior. They know that you’ve taken good care of your car and that can make them more likely to give you top dollar for it.

PPF film to get the most return on your investment

Nothing could be more different from your ant's useless coats than PPF Film for your car, an investment in protecting and enhancing your car’s exterior that is also money in the bank. And when you sell your vehicle, you can get a higher price for your car because your Purchase PPF Helped it maintain the new car-like appearance. That means that should you ever decide to sell your car, you can receive even more money for it with invisifilm, making it a savvy purchase for any car owner.

Why you should regard PPF film as a smart investment in resale value

As alluded to before, installed car ppf Film on your car can make it more appealing to potential buyers. They will notice that your car has been well-cared for, and that will effect how at ease they are when considering the computing that they won’t have to put more money into repairs. This could make your car look unique compared to the other cars and can significantly add up to the value of your car if you want to sell it again.

The advantages of PPF film for your car’s exterior are here to stay

And lastly, discuss the long term benefits PPF Film will always help maintain to your cars exterior. PPF Film is made with long term durability in mind, to protect and preserve your surfaces for at least a decade. If well-maintained, your car’s finish will stay looking new as long as you own your vehicle and help to maintain and preserve its value PPF Film is hands down a good investment for anyone.

To sum it all up: KPAL FILM ppf film is a great solution to Save, Respect and Profit in your car. With PPF Film, you can keep your car looking pristine and protect your vehicles resale value for those down the road return on investment, potential buyers, and long-term benefits. If you still want your car to look new when you decide to sell it, it also needs PPF Film.