@traspino

- Followers 0

- Following 0

- Updates 338

Category: Why Stainless Steel May Fail in Strong Acid Applications

Stainless steel is a hard and rugged material which allows it to be used in a wide variety of applications where it will not bend or break and its excellent resistance to corrosive and rusting. Stainless steel is not the best material, at least in strong acid conditions. Strong acids have high acidity and can corrode stainless steel quickly which can cause it to weaken or fail.

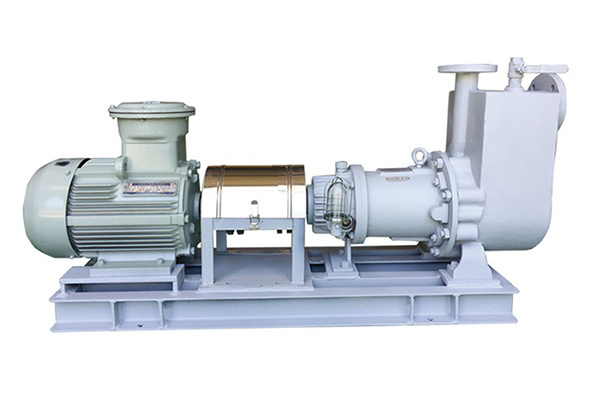

The strong acidity of strong acids, such as sulfuric acid and hydrochloric acid, can have a chemical reaction with the components of stainless steel, resulting in rapid corrosion. Such corrosion may cause a decrease in the strength of the stainless steel causing it to fail in an overly stressed or pressured environment. The stainless steel centrifugal pump in some cases can even snap or collapse, risking anyone standing nearby.

[Stainless Stell is vulnerable to pitting and crevice corrosion in even acid environments.] A few powerful acids that can damage 304L include hydrochloric and sulfuric acids. Pitting Pitting occurs when the surface of stainless steel is attacked by small holes or pits which lighten it and weaken it over time. Crevice corrosion, by contrast, occurs wherever there is a small space or gap in which the acid becomes entrenched, and localized corrosion and a threat of failure can result.

Strong acids can cause stress corrosion cracking of stainless steel, hairline cracks that cause failure. Stress corrosion cracking is a corrosion that happens when the stainless is under tension and in a corrosive atmosphere. However, when stressed and in an acidic environment, the stainless steel can crack, which is unacceptable for use in critical applications.

Strong acid service and high temperatures can accelerate corrosion of stainless steel sump pump resulting in premature failure. Under high temperatures and intensities of strong acid, the rate at which the corrosion occurs increases and the metal becomes weaker more quickly. This can contribute to the premature weakening and eventual failure of the stainless steel.

Some stainless steels Do not use with some powerful strong acids, such as sulphuric acid which will result in rusting and possible failure of the application. This steel grades resistance to corrosion and staining, low maintenance, and familiar luster make it an ideal material for many applications. If the incorrect grade of stainless steel is used in a powerful acid environment, for example, deterioration and failure can be the consequence as suitable resistance to the acidic environment may not be provided.

In summary, although stainless steel gear pump is a versatile, common material that can be immensely effective, it’s not the best option in every case not at least for strong acid applications. The extreme acidity of strong acids can lead to fast corrosion, pitting & crevice corrosion, stress corrosion cracking, accelerated corrosion at higher temperature and incompatibility with some types of stainless steel. If you're planning to work with stainless steel in a highly acidic situation, take the time to evaluate potential risks and select a suitable material first, the safety and life expectancy of your application depend on it. Just remember when it comes to those strong acids, be sure to choose wisely and realize The Risk of using stainless.