@traspino

- Followers 0

- Following 0

- Updates 338

Category: PP sheet production process and common problem solutions

Outline of the process of producing a PP sheet from polymerization to extrusion

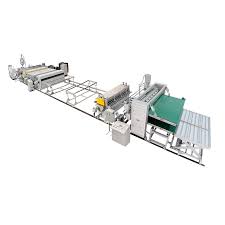

The Good price PP sheet extrusion line is produced by the polymerization of propylene monomer and subsequent Orientation of these polypropylene chains to form long molecular chains. Those polymer chains are melted and melt-extruded into a flat sheet by the most high-technology equipment of JWELL Machinery. This sheet is subsequently cooled and cut to size and shape.

Common faults and troubleshooting methods for the production of PP sheet

Although the existing technique has advanced, problems such as uneven thickness, bad surface quality, warping are still prone to pp sheet production. Extrusion temperature, screw speed and cooling should be tested to solve these problems. It is possible that variations of these conditions could help in having better quality of PP sheet.

Quality control of PP in sheet production to avoid defects

Quality control can be more important to the production of jwell PP sheet extrusion line to avoid web/film defects. Checking raw materials for impurities, monitoring the process for uniform extrusion, and performing regular machinery maintenance can help avoid errors such as bubbles, streaks and black spots in the finished product.

Optimization of productivity of PP sheet 1R production

In addition, industry that requires high productivity is making the utmost effort in PP sheet production. Optimization approaches such as the increase in production speed, reduction of downtime, and increase in energy efficiency, so that they can be used to improve the efficiency of the system. Cutting edge technology from JWELL Machinery can also help you to improve the production process to ensure you have a more cost-effective working process.

Creative solutions for sustainability in the PP sheet product organising sector

The increasing customers’ requirement for pp sheet extrusion machine makes it necessary to pay more attention to sustainability during production. Aggressive ways such as recycling of waste, efficient use of material and utilizing renewable sources of energy will facilitate in achieving sustainability in the PP sheet industry. JWELL Machinery is faithful to creating environmentally efficient products that reduce the harm to the environment through production processes.

Taken together, the production of PP sheet is a complicated process from polymerization to extrusion with some factors affecting the quality and efficiency of production. JWELL Machinery has introduced advanced technologies from developed countries to make the quality of the PP sheet that we produce high as well as making our products be in a good condition by producing them according to the PP sheet production standard through such measures as performing troubleshooting and control, systemic control, adopting optimization technology and developing our own kernel product.