@traspino

- Followers 0

- Following 0

- Updates 206

Blog

HBOT s effects on stroke, TBI (traumatic brain injury), and cognitive decline

By traspino, 2025-08-08

Improving Brain Function and Mobility

When something like a stroke, traumatic brain injury (TBI), or cognitive decline occurs to a person, it can impact his or her brain function and the ability to move. These factors can make it difficult for them to get up and think straight. But a therapy called hbot hyperbaric oxygen therapy is making a big difference in brain function and mobility for those with these diseases.

The HBOT treatment delivers more oxygen to the brain than it would typically receive. This additional oxygen can promote better brain healing and function. That's why patients can experience the improvement in their mobility, stability, and coordination through HBOT therapy. This allows them to move around more freely and to carry out daily activities with greater ease. It’s like supercharging your brain so it can do its job better!

Improving Cognition and Brain Function

As well as aiding with mobility, HBOT can also increase cognitive and neurological function in patients. That is, it can make people think more clearly, remember better and focus harder.

When some people’s brains are hurt following a stroke, TBI, or in the course of cognitive decline so are their cognitive abilities. They might forget things or have difficulty learning new information or making decisions. Fortunately, with HBOT therapies, these cognitive functions can be strengthened and enhanced. Many patients say that they feel 'sharper,' 'more alert,' and 'more focused' after their hbot chamber treatment. This can make a huge difference in their daily lives and their activities.

HBOT – Changing the Way We Do Things Battle wounds are typically open wounds.

HBOT is also an emerging treatment for stroke, TBI, and cognitive decline. Rather than just addressing the symptoms of these disorders, HBOT aims to heal the brain and enhance its function. It is a game-changer for patients who seek to recover and regain independence.

Conventional methods of treating stroke, TBI, and cognitive decline typically address the management of symptoms and care. Although such treatments can be beneficial, they do not necessarily treat the underlying problems in the brain. HBOT, by contrast, focuses specifically on the brain and directly supplies the oxygen it requires in order to repair and function more effectively. This customized nature of the treatment, in essence, is what makes HBOT so remarkable in the new landscape of treatment options for these conditions.

The Potential of HBOT in Restoring Function of Stroke and Traumatic Brain Injury Patients

Stroke survivors and those with TBI are just one group who can greatly benefit from HBOT. These persons frequently encounter serious obstacles during the recovery process due to physical inabilities, cognitive disfunction and neurological residuals. But with HBOT, they have a powerful weapon to help them maximize their rehab potential, and recovery.

Through the administration of HBOT treatments, stroke victims and TBI sufferers can experience advancements in mobility, cognitive function and total brain health. This can help restore their independence, quality of life and overall health. With HBOT's potential in rehabilitation, these individuals have a new road to recovery and a chance of new life.

A Reader’s Guide to the Latest Developments

The literature on interest on HBOT and stroke, TBI and cognitive decline is dynamic. Recent research and discoveries are beginning to reveal the transformative potential of this therapy in treating brain function and motion, cognitive increase and in the approach to new treatments for these conditions.

Recent studies revealed that hbot oxygen therapy might promote neuroplasticity, which is the potential of remolding and reorganization of the brain postinjury. This translates into the ability for HBOT to assist the brain to heal and create new connects and therefore improve mobility, cognition and neurological function. These results are stimulating for patients, families and the entire medical community because they offer hope and are a promise for a better future with HBOT.

In summary, HBOT holds promise as a therapy for stroke, TBI and cognitive deterioration. HBOT is already in many cases a game changer for these patients, by reversing brain dysfunction, increasing brain mobility giving patients drastically improved cognitive and neurological functions as well as providing and giving rehabilitations still not available with medical therapies. Led by Baobang, this revolution means that the care, support and hope that patients deserve to live and get well, is now possible.

What is the difference between monitors in the intensive care unit (ICU) and general wards?

By traspino, 2025-08-08

In hospitals, monitors are various models that track patients’ health. ICU monitor is a type of monitor used in intensive care unit. The ICU is the area in the hospital reserved for those who are very sick or critically injured. ICU monitors are very different from the monitors of general wards in various aspects. Icu monitor vs General Ward Monitors, let’s find out the difference between them.

The data that ICU monitors offer in high resolution on individual patient vital signs in real time.

ICU monitors are specialized instruments that deliver instant, detailed information about a patient’s vitals. Vital signs are measurements of things like heart rate, blood pressure, level of oxygen in the blood, and temperature. There are wires and sensors that are attached to the patient to get all of this vital information (sounds like a lot, I know). The information gathered by an ICU monitor is presented on screens for doctors and nurses to view. This allows them to closely monitor a patient’s health and decide how to care for them.

An appreciation of the sophisticated nature of ICU monitoring relative to ward equipment.

ICU monitors are different from those in the general ward facilities, and have special features. ICU monitors can monitor more biology concurrently, even including the patient’s brain activity and the pressure in their lungs. The monitors also have alarms that sound when a patient’s vital signs are not within the normal range. This can enable the medical team to react faster to any changes in the patient’s condition.

The value of longitudinal monitoring of the ICU environment in critically ill patients.

It is necessary to monitor the patients who are critically ill, particularly in the ICU. So the patient is being monitored 24/7, day and night. Icu monitor reading enable the medical staff to keep close tabs on the patient’s wellness and to catch any problems early. This enables them to do their best for the patient.

How ICU Monitors Help Respond Faster to Acute Patient Status Changes.

The ICU monitor is vital for the medical team to respond promptly to changes in a patient’s condition. For instance, if a patient’s heart rate abruptly accelerates, the ICU monitor will blare an alarm. This triggers the medical staff that there is someone in urgent need of help. Because of the data that the ICU monitor provides, doctors and nurses can respond quickly to help the patient and hopefully prevent any serious complications.

ICU monitors: their role in better patient care and outcomes.

Monitoring of the ICU is necessary to obtain better outcomes for patients and safety in the intensive care unit. In addition to detailed, up-to-date statistics, these monitors also allow the medical staff to make sound decisions about treatment. This results in better treatment and a greater chance of recovery to the patient. ICU monitors also aid in preventing medical errors and complications to protect the safety and well-being of the patients.

In summary, ICU patient monitor are unique instruments that are essential for the care of patients with critical illness in the hospital. They give the medical staff more detailed real-time data and have more functionalities to help monitor the patients closely. Because of the ICU monitor, doctors and nurses are able to immediately react to any changes in a patient’s condition that can translate into better outcomes and patient safety. SkyFavor Medical is dedicated to supporting the global fight and work of medical personnel, striving to provide superior and quality medical equipment such as icu monitor to offer patients the best technology that money can buy.

There are different kinds of compressors that are utilized in the oil and gas industry that can help perform a variety of tasks. Compressors are machines that assist in raising the pressure of gas, to move it through pipelines or to process it for various other purposes. We use a variety of portable air compressor at Kotech to run our business in the most efficient and effective way.

Reciprocating Compressors

Reciprocating compressors are among the widely used compressors in the oil and gas industry. These compressors compress the gas with a piston and then transfer it to a piping array to pressurize it. In gas processing plants, reciprocating compressors are used to assist in the separation of the various gases, and to boost their pressureto where they can be further processed for transportation.

Oil and Gas Centrifugal Compressors

Centrifugal air compressor are another oil and gas industry compressor category. Centrifugal compressors, however, rely on a spinning impeller to elevate the pressure of the gas. They are frequently mounted near a wellhead for purposes of drawing gas from below ground and boosting the pressure needed to carry the gas through lines to a common point of collection.

Screw Compressors for Upstream Operations

Upstream in the oil and gas industry, screw compressors can be found in use. Two rotating screws are driven to compress the gas, resulting in pressure build up. Screw compressors are widely used in drilling sites to aid in bringing gas to the surface and preparing it for transport through pipes.

Scroll Compressors for Downstream Processes

Down-hole applications in scroll compressors oil and gas are more broadly employed. These compressors operate based on two interleaving scrolls to compress the gas and raise its pressure. Refineries and processing plants often use scroll compressors to aid in refining and processing gas for various purposes.

Diaphragm Compressors for Gas Plants

Typical applications are in oil and gas process plants, where diaphragm compressors are a preferred type. Such compressors operate on the principle that the gas is compressed by a flexible diaphragm to high pressure. Diaphragm compressors are commonly employed at gas processing facilities to aid in the separation of the various gases and to raise the pressure of the gas and expel it either pneumatically or mechanically.

So, in summary Kotech utilises different type of compressor including in the oil and gas industry to ensure company work effectively and efficient. Each of these types of screw compressor operates differently and achieves its purpose of compressing gas to increase pressure to be used for tasks. We can guarantee an efficient production process by selecting the appropriate compressor for each specific process.

A lot goes into construction, especially when you’re dealing with structures as those of secant pile walls. Usually, these walls are used to provide a building with stability. But there are a few errors you can make that will cost you so it’s good to try to avoid them.

Appreciating the Value of Adequate Alignment in Secant Pile Wall Design

Accuracy is highly important in the construction of cfa secant pile wall . Where the piles have not been properly aligned, the result can be a wall that is unsound and unstable and is unable to support the above structure. The Correct Tools and Techniques Must Be Used During Construction to Achieve Proper Alignment. KIMDRILL recommends that only experienced construction teams familiar with proper alignment of secant pile walls to carry out the sepage treatment.

Preventing Mistakes in Shear Reinforcement Layout For Pile Walls

Another important issue in the construction of secant bored pile wall is reinforcement placing. Reinforcing rods are installed in the right places and the right direction so your wall is strong and stable for the long haul. Reinforcing is often misplaced through incorrect centre-spacings, wrong bar diameters and inadequate bar overlap. Due to the high cost, strict adherence to the above design specifications are necessary, as well as a thorough verification of reinforcement drape prior to concrete placement. KIMDRILL (2017) also stresses the importance of correct location of reinforcement on the behavior of secant pile walls.

The Importance of Proper Grouting to Avoid Costly Errors in Secant Pile Wall Development

The grouting is an important process in secant piles construction and is performed to fill the cavities between the piles and stabilize the wall. On the other hand, if grouting is not correctly performed voids, leaks and other deficiencies can be formed and which can damage the integrity of the wall. It is critical to use the appropriate grout, adhere to appropriate mixing and pumping procedures, and control the grouting process, to avoid making costly mistakes. KIMDRILL suggests that qualified grouting people to be used in accordance with correct grouting methods.

Key Mistakes to Avoid

Some common faults to be prevented in the construction of secant pile walls are lack of proper site investigation, poor on site communication between the construction team, inadequate quality control and disregard of safety regulations. Any potential problems or issues should be identified during a comprehensive site investigation before the construction begins. Proper communication between all the members of team is also required to keep everyone on a single page and working towards the same goal. Early detection is key: Quality control measures like regular inspections and testing can help locate and fix issues before they become problems. And last but not least, a commitment to safety at the worksite is also your best protection against an accident and injury that can cause time delays and drive costs higher.

HOW TO OVERCOME MATURING CHALLENGES OF EXCAVATION & BACKFILLING AND AVOID COSTLY MISTAKES IN SECANT PILE WALLS

Excavation and backfilling are tricky works at the time of construction of secant pile wall. The wall needs a good stable foundation, so you’ll want to employ good excavation techniques so that you have a nice simple base that’s not likely to shift much over time.Base fill should be done carefully so as not to force much more pressure on the wall. Typical mistakes in excavation and backfilling are over-excavation, using wrong backfill materials, and inadequate compaction of soil. In order to successfully face these challenges and avoid needless expenses and costly mistakes, make sure to employ experienced excavation and backfilling contractors with the proper materials and the capabilities to get the job done right. KIMDRILL emphasizes the necessity of adequate excavation and backfilling methods for the final stability and durability of secant pile walls.

In summary, secant bored pile wall construction needs to be carefully planned, detailed and constructed through sound construction practices to avoid costly errors. "If you think about it, the better your alignment, the better the struts and braces go in; the better the braces go in, the stronger the wall you have," he says "Keeping as much space as possible between reinforcements makes the wall more solid and is going to last so much longer." "You can work around any challenge -- with the right equipment," he says. KIMDRILL is dedicated to offering the best equipment and team to ensure that secant pile walls are constructed correctly.

Stainless steel is a hard and rugged material which allows it to be used in a wide variety of applications where it will not bend or break and its excellent resistance to corrosive and rusting. Stainless steel is not the best material, at least in strong acid conditions. Strong acids have high acidity and can corrode stainless steel quickly which can cause it to weaken or fail.

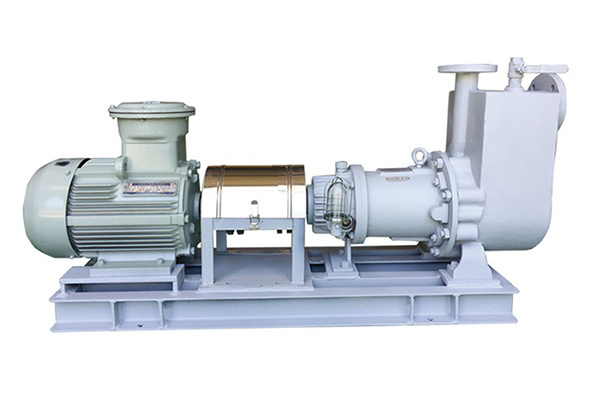

The strong acidity of strong acids, such as sulfuric acid and hydrochloric acid, can have a chemical reaction with the components of stainless steel, resulting in rapid corrosion. Such corrosion may cause a decrease in the strength of the stainless steel causing it to fail in an overly stressed or pressured environment. The stainless steel centrifugal pump in some cases can even snap or collapse, risking anyone standing nearby.

[Stainless Stell is vulnerable to pitting and crevice corrosion in even acid environments.] A few powerful acids that can damage 304L include hydrochloric and sulfuric acids. Pitting Pitting occurs when the surface of stainless steel is attacked by small holes or pits which lighten it and weaken it over time. Crevice corrosion, by contrast, occurs wherever there is a small space or gap in which the acid becomes entrenched, and localized corrosion and a threat of failure can result.

Strong acids can cause stress corrosion cracking of stainless steel, hairline cracks that cause failure. Stress corrosion cracking is a corrosion that happens when the stainless is under tension and in a corrosive atmosphere. However, when stressed and in an acidic environment, the stainless steel can crack, which is unacceptable for use in critical applications.

Strong acid service and high temperatures can accelerate corrosion of stainless steel sump pump resulting in premature failure. Under high temperatures and intensities of strong acid, the rate at which the corrosion occurs increases and the metal becomes weaker more quickly. This can contribute to the premature weakening and eventual failure of the stainless steel.

Some stainless steels Do not use with some powerful strong acids, such as sulphuric acid which will result in rusting and possible failure of the application. This steel grades resistance to corrosion and staining, low maintenance, and familiar luster make it an ideal material for many applications. If the incorrect grade of stainless steel is used in a powerful acid environment, for example, deterioration and failure can be the consequence as suitable resistance to the acidic environment may not be provided.

In summary, although stainless steel gear pump is a versatile, common material that can be immensely effective, it’s not the best option in every case not at least for strong acid applications. The extreme acidity of strong acids can lead to fast corrosion, pitting & crevice corrosion, stress corrosion cracking, accelerated corrosion at higher temperature and incompatibility with some types of stainless steel. If you're planning to work with stainless steel in a highly acidic situation, take the time to evaluate potential risks and select a suitable material first, the safety and life expectancy of your application depend on it. Just remember when it comes to those strong acids, be sure to choose wisely and realize The Risk of using stainless.

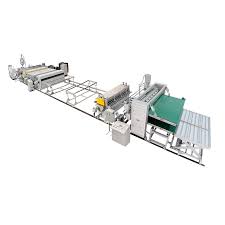

Outline of the process of producing a PP sheet from polymerization to extrusion

The Good price PP sheet extrusion line is produced by the polymerization of propylene monomer and subsequent Orientation of these polypropylene chains to form long molecular chains. Those polymer chains are melted and melt-extruded into a flat sheet by the most high-technology equipment of JWELL Machinery. This sheet is subsequently cooled and cut to size and shape.

Common faults and troubleshooting methods for the production of PP sheet

Although the existing technique has advanced, problems such as uneven thickness, bad surface quality, warping are still prone to pp sheet production. Extrusion temperature, screw speed and cooling should be tested to solve these problems. It is possible that variations of these conditions could help in having better quality of PP sheet.

Quality control of PP in sheet production to avoid defects

Quality control can be more important to the production of jwell PP sheet extrusion line to avoid web/film defects. Checking raw materials for impurities, monitoring the process for uniform extrusion, and performing regular machinery maintenance can help avoid errors such as bubbles, streaks and black spots in the finished product.

Optimization of productivity of PP sheet 1R production

In addition, industry that requires high productivity is making the utmost effort in PP sheet production. Optimization approaches such as the increase in production speed, reduction of downtime, and increase in energy efficiency, so that they can be used to improve the efficiency of the system. Cutting edge technology from JWELL Machinery can also help you to improve the production process to ensure you have a more cost-effective working process.

Creative solutions for sustainability in the PP sheet product organising sector

The increasing customers’ requirement for pp sheet extrusion machine makes it necessary to pay more attention to sustainability during production. Aggressive ways such as recycling of waste, efficient use of material and utilizing renewable sources of energy will facilitate in achieving sustainability in the PP sheet industry. JWELL Machinery is faithful to creating environmentally efficient products that reduce the harm to the environment through production processes.

Taken together, the production of PP sheet is a complicated process from polymerization to extrusion with some factors affecting the quality and efficiency of production. JWELL Machinery has introduced advanced technologies from developed countries to make the quality of the PP sheet that we produce high as well as making our products be in a good condition by producing them according to the PP sheet production standard through such measures as performing troubleshooting and control, systemic control, adopting optimization technology and developing our own kernel product.

When you think custom size non woven bags from Lvjing Packaging, there are a few things that you have to consider. There are few things you need to consider while buying and those could be crucial for getting the right bags for your work.

So what are you going to place in the bags? Do we use to transport my books, food or something else? Now we know what the Nonwoven Bag are going to be used for, we can work out how big they need to be. You do not desire them to be so small that they cannot fit whatever you require, nevertheless on the other hand, you likewise do not desire them to be too big and large.

You also need to understand the types of non-woven materials that are used. Non-woven is something that means fabrics which are not woven. Non-woven fabric is of different types such as polypropylene, polyester etc. Each type of hash has it's own pro's and con's. Different materials are stronger, and other materials are more flexible. What determines this is what the bag will be used for, and what material you choose for it.

Custom bags environmentally sustainable options. Consider purchasing bags that are fully recyclable in a standard curbside program. This is key to help sustain our planet and ensuring it stays clean and healthy for the future.

Designing options, and printing techniques for personalized Nonwoven bag market analysis are a lot of fun when it comes to custom non-woven bags. Different coloured and patterned bags are available to create an eye catching unique style for your product. Apart from that, you can also select how the design needs to be printed on the bags i.e. screen print, heat transfer and many other styles. It is a golden opportunity to be creative and make your bags differ.

The last thing to consider when ordering custom size non-woven bags is striking a balance between quality and cost. These are things are used daily and you want to ensure you get well-made bags that will be around for a while. Yet at the same time you also want to ensure that you are getting a great price and not paying any more than absolutely necessary. Find a tradeoff between quality and budget that effectively works for you

Overall, whether you purchase the custom size non woven bag from Lvjing Packaging, it will be certain that you have to keep above points in your mind regarding the size, material, sustainability, designability and cost. Thinking about all of them any consideration will give you the best bags for what you require used that are useful as well as fashionable. We can offer you the detailed advices, from which options you should choose to what kind of bags you are going to have. I cannot wait to see all the wonderful custom bags you create.

Sick of losing your favorite lip gloss or digging through a pile of clutter only to find the wrong shade of eye shadow? Well, Hotop has developed an incredible bag that addresses all your make up messes and simplifies the method of getting ready in the morning.

This game changing makeup bag clears away the clutter.

With our Hotop cosmetic bag , now you can bid farewell to all the fuss from storing all your beauty products. This revolutionary makeup travel bag is an exclusive bag that organizes all essentials while providing easy access to products while on the go. No more digging through drawers or pull-through bags to find that one lipstick you absolutely love. Every bit will have its special place in your Hotop makeup bag.

Organize all of your cosmetics into one location for access.

The best thing about the Hotop pouch is that you can store all your makeup in one central location and conveniently take it with you as you travel. No more searching for your mascara or blush, when you can open your bag and have everything you need there. Whether that’s getting ready for school, a dance recital, or a family party, when you have all of your beauty products in one location it just makes things go more smoothly and it’s a lot less stressful for everyone.

The cosmetic bag is the perfect way to organize all your beauty essentials and simultaneously a beautiful ornament of your beloved bags.

Not only is the Hotop makeup bag super practical and functional, but it’s also very cute. It’s trendy colors and sleek body style make it an essential fashion accessory for your beauty needs. There are several different colors and patterns you can select to fit your own style and give you a little extra fun in your makeup. Who knew stashing your beauty essentials could be so chic.

Never rummage through a cluttered makeup drawer again with this quick fix.

If you have been tired of having your cosmetics all over the place, then the Hotop Cosmetic Makeup Bag is the perfect solution for you. Never again hunt for the perfect lipstick, blush or eyeshadow. Now your set will remain beautifully organized on one place and its compact size will save space and help maintain tidiness in your bathroom and luggage.

This game-changing bag takes the work out of your beauty routine.

With HS lining make your beauty tools organized and convenient to find with this bag from Hotop. Gone are the days of fumbling about trying to find your make-up everything you need will now be perfectly organised and at hand. You’ll be surprised at how much simpler and more effective your morning gets with the help of this revolutionary bag.

In summary When you’re fed-up of disorganized makeup getting in the way of your daily beauty routine, then the Hotop cosmetic bag is the solution to all your problems. This will transform what is typically viewed as just another cosmetic bag into not only a gorgeous accessory for on the go but also a glamorous storage place for at home. Say goodbye to clutter and chaos, and hello to an easier, more organized beauty routine with the Hotop Man Cosmetic Bags . Order yours today and feel it for yourself.