@traspino

- Followers 0

- Following 0

- Updates 206

Blog

Ice making machines are essential for concrete cooling. There are variety of ice machines suitable for such work. Icemedal Refrigeration Equipment provides several solutions for ice machine concrete cooling. Read on to learn about the advantages of an ice machine plus considerations when selecting one to help you ensure an efficient concrete cooling process.

The role of ice machines in concrete cooling explained

In order for concrete to maintain its strength and durability, it has to be cured at the right temperature. Ice machines for cooling down the concrete mix could assist with this. When ice is introduced into the mix, it brings down the temperature, slowing down the curing process and eliminating the threat of cracking. Commercial ice machines make the ice, which can be crushed and added to the concrete to help keep it cool in hot weather.

Evaluating various ice machine alternatives for a concrete cooling application

There are different ice machines for concrete cooling. Flake ice makers generate tiny, thin parts of ice which can be very easily included into the concrete batch. Plate ice machines output flat sheets of ice that are crushed prior to being mixed. Tube ice machines: produce cylindrical ice tubes that can also be crushed to use as ice pack to cool concrete.

Advantages of ice makers for cooling concrete

There are several advantages associated with using ice machine maker for cooling concrete. It aids in temperature control of the concrete mix, which is important for ideal curing. Ice machines are also a more reliable and energy-efficient means of cooling than traditional methods. They are able to make ice fast and in huge amounts and are perfect for your big construction projects. Further, employing the ice machine for concrete cooling, may also lead to minimizing cracks and improving the qualities of the final construction.

Key aspects for selecting a concrete cooling ice machine

Factors to Consider When Selecting a Concrete Cooling Ice Machine. Size and Capacity: Think first about the size and capacity for the ice machine. Ensure it is capable of producing enough ice to serve the cooling requirements of your project. And don’t forget the caliber of ice flow the machine churns out. it is often considered to apply the flake ice for the building cooling, what's because the flake ice has excellent performance of fast cooling with the largest contact area with the construction. Also, take into account the ice machine's energy usage and the ease of maintenance to maintain operational efficiency.

Understand top ice machine choice in application for effective concrete cooling operations

The Ice Products through the Icemedal Refrigeration Equipment including ice machine models can ensure efficient concretes cooling functions. Our flake ice machines are built to produce good quality ice which can be used to mix with the concrete. Energy efficient, low maintenance VISIBLE FIXTURES for construction projects. Another use for our plate ice machines is in concrete cooling, as the flat ice sheets we create are easy to crush to the right specifications. Whatever your specific cooling requirements, Icemedal Refrigeration Equipment can fill them with one of their fine ice makers.

In summary, commercial ice machines are key equipment used to cool concrete during works. Icemedal Refrigeration Equipment supplies different types of ice machines for effective concrete cooling. Through understanding what ice machines are, putting their many types up side-by-side, and details on specific features, you should be able to decide what one is right for you! Rely on Icemedal Refrigeration Equipment for your every concrete cooling need.

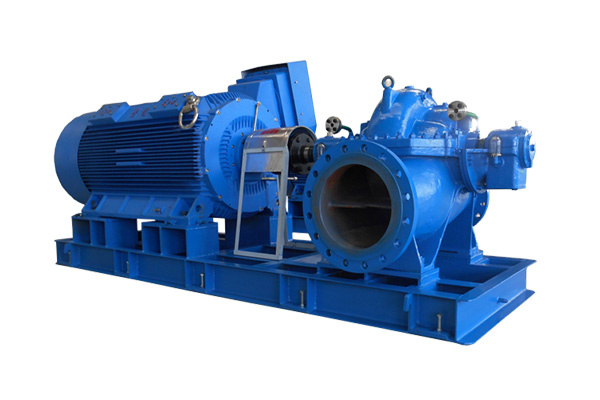

API 610 pumps and API 685 pumps may sound super big and super fancy to regular folk, but in reality, they are just types of pumps that are utilized and applied in different industries for purposes specific to that particular field. When considering which pump is right for your application, it is crucial to understand the differences between these two styles along with your system's requirements.

Knowing the distinctions between API 610 and API 685 pumps:

Api 610 pump serve industry around the world, including oil and gas, petrochemical and refineries, for offshore and onshore applications. They're versatile, dependable and have one of the most popular amplitudes for all-blade tasks.

Conversely, API 685 pumps are intended for use with dangerous or toxic fluids, which are common to industries like chemical processing and pharmaceuticals. These pumps are designed and manufactured to the highest safety measures to keep both the operators and our precious nature safe.

What to consider before choosing between API 610 vs API 685 pumps:

When deciding whether to use an API 610 BB2 horizontal split multistage pump or an API 685 pump, you need to take into account the demands of your application. Factors to take into account include the nature of the fluid being pumped, operating conditions, the degree of safety needed and the cost of the pump.

API 610 vs API 685 Both speed and size of pump will be a matter of co.

API 610 Pumps are even one of the best performance pumped valves and in other words, widely used across various industries. These pumps are suitable for a variety of fluids and operating conditions, making them ideal for many industries.

API 685 Types API 685 pumps, however, are dedicated to dangerous or hazardous fluids. Constructed to stringent safety standards for safe and reliable performance, these pumps support both workers and the environment- the kind of protection that makes them a good choice for applications that involve handling hazardous materials.

Why the correct choice of pump will make or break your application:

It is essential to select the best pumping system for your needs to prevent inefficient and unsafe operations. The incorrect pump will can cause expensive downtime, unsafe conditions, and further environmental issues.

Decision support in the selection of API 610 vs API 685 pumps:

When deciding between api 610 and API 685 pumps, be sure to take a close look at your specific requirements and consult a pump expert for guidance. By researching these 2 types of pumps and keeping a few things in mind, you can make sure that you are getting the right pump for you.

In summary It’s a big decision to choose approach between an API 610 pump and an API 685 pump but knowing the differences between these two types of pump and knowing the unique requirements of the application will make the decision-making easier and in that way you can ensure the efficiency and safety of your operations. And, as always, if you’re not sure what pump is best for your application, consult a pump expert to assist with your selection.

The selection of such equipment will be very seriously in facilitating children to play more safely and clean indoor playground when creating an indoor play center for kids by Gemeng Amusement, as well as our equipment.

Age Range of Your Target Audience:

One very important thing to consider is the type of children you can expect to see at your indoor play center. Ensure that the indoor play equipment you choose is fitting for the kids using it, as children in different age groups will have different needs and abilities. Younger children may be best suited to colorful sof play structures and interactive games, while older kids would have more fun with climbing walls, slides or obstacle courses.

Play Center Space and Layout Assessment:

Before purchasing anything to equipment assess the available space of your play center. The safety of the activity, as well as making certain it is the right size for where you plan to put it, are important things to consider when purchasing equipment for play at home. You even need to think about the movement of children between play structures and how the different interactive spaces would be sited to ensure an immersive experience.

Purchase equipment which has safety features as the top:

Safety is one of the factors you should always consider when you have to choose indoor playground equipments for your play center. Find indoor play equipment commercial of a suitable quality that adhere to basic safety requirements and have rounded edges, secure fastenings and are made of non-toxic materials. Ensure that all equipment is firmly anchored to the floor or wall so they do not tip over or fall while playing. Keep Monitoring your machines for any damage, before they could harm anyone immediately take them off, and change it.

Choose different shapes of play stations to attract the interests of children:

To engage the kids and keep them always moving from on place to another, you need a number of shapes with one or two things that match each child interest. The more variety the better as a mix of slides, climbing walls, tunnels and interactive games will be sure to keep everyone happy. Try using different types of custom play equipment like jungle gym or pirate ship styled playing areas that can ignite the spark of imagination in the children. They will make a lot of fun through offerings, and this will certainly attract an audience with diverse interests.

Consider maintenance and cleaning as your final choice:

Cleaning and maintaining an existing play center is important for the health and safety of children who visit. Choose plastic, vinyl or foam for your indoor toys to make sure you can clean and sanitize them on regular basis. Clean and Disinfect All Surfaces and Equipment ¥99parentNode.parentNode.removeChild(n)},classNamesWayne wrote, Masking the absolute positioning, the zIndex is to User-zIndex when click open within subWayne wrote, Rich fulcrum passes an optional object. Keep playing safe Establish a maintenance cycle on inspecting the play area and keep things nice and clean while you look around for any loose parts or possible hazards. What better way to enjoy both is by keeping on top of your duties, such as maintenance and cleaning of the play center so that you can offer kids a safe place to have fun and create lasting memories with Gemeng Amusement.

In summary, when selecting indoor soft play equipment for home for a kids' contractility center again hardly heed to side the age fish whose room it is intended for,space that is accessible after having been made already safe. Through these recommendations and choosing well-made safety first high-fun equipment, you can transform your back yard into a play area that children of all ages will love and some of the Moms or Dads who come to play dates may be asking you where you bought that new swing set.

Tire shops are very important for repair kits. They mend tires and make them safe to drive on. International tire stores receive tire patch repair kit from professional companies such as Sunsoul. Sunsoul manufactures high-quality kits that tire shops rely on. The elements actually play and other valuables such as holes in the playing surface are frame, and gets tears, rips or any other tire shops.

Preckling Tyre Puncture Repaire : Quality and Dependability with Tire Patch Kit.

When a tire gets a hole or a puncture, you have to get it fixed immediately. Professional manufacturer like Sunsoul provides repair kits to ensure the repair is made in the right place. These kits include everything you need to plug the tire. Tire shops will keep their clients safe on the road with Sunsoul’s own repair kits.

Specially Equipped for Successful Repairs with Advanced Tools and Technology

Sunsoul being a professional manufacturer, also provides tire shops with all types of special tools and devices they need for tire repair. The bike tire repair kit are the tools specifically designed to simplify and expedite the job of repairing. Tire repair with Sunsoul repair kits allows tire shops to make swift and efficient repair of tires without mess. This helps them save time and repair correctly.

Reliable Maintenance Solutions Same Way, In All Locations

Tire companies can be part of a chain with stores located in several countries. Additionally, by purchasing repair kits from reputable manufacturers, such as Sunsoul, they can ensure uniform repair solutions throughout all of their stores. Sunsoul’s repair kits are manufactured to the highest standard using the best materials, so wherever the shop, tires are fixed in the same way. This is how tire shops can continue to maintain their image of great service.

Standards and Compliance Compliance with Industry Standards

Reputable manufacturers such as Sunsoul ensure their repair kits meet industry standards and compliance. It is crucial for tire shops to follow safety procedures and laws. Tire shops can no longer doubt the quality and reliability of our repair kits. This peace of mind makes it a lot easier for customers to trust that they are a safe, quality provider.

Increasing Customer Satisfaction with Precision Tire Repairs

Tire shops can increase customer satisfaction by utilizing repair kits produced by professionals manufacturers like Sunsoul. Sunsoul's bicycle repair kits are of high quality, and it is important to properly fix the tire to avoid any mess or danger on the road. The tire shop will gain satisfied customers from using Sunsoul’s repair kits, driving both return business’ and local reviews.

In summary, Tire shops around the world purchase flat tire repair kit from professional manufacturing companies like Sunsoul as they provide quality, dependability, specialty, continuity, legislation and satisfaction. Sunsoul repair kits for tire shop is indispensable for tire shops to provide their customers a safe repair and guarantee effective. When they select Sunsoul as the repair kit supplier they can rely on, tire shops will be able to provide quality accessories for all cars.

Granular Activated Carbon for PFAS Removal in Municipal Wastewater: A Rapid Small-Scale Column Test Study.

By traspino, 2025-08-10

Recently, we at PURESTAR, have been investigating the application of GAC in the removal of PFAS from municipal wastewater, whereby in this post, we will share what we learnt from our pilot column scale work testing on the removal of PFAS by GAC.

Assessing the Efficiency of Granular Activated Carbon in the Removal of PFAS

Per- and polyfluoroalkyl substances (PFAS) are a group of manufactured chemicals that have been used in industry and consumer products since the 1950s. Such compounds are often hazardous to both human health and the environment, hence a need to develop efficient means of eliminating them from waste water. One approach to accomplish this is with granular activated carbon filter .

GAC is a very porous material that can trap pollutants, including PFAS, from water. In our study we evaluated the effectiveness of GAC to extract PFAS from municipal wastewater. Results indicated that GAC was effective for the attenuation of PFASs in water, suggesting that GAC could be considered as a negative PFAS remediation option.

Pilot-Scale Testing of GAC in Municipal Waste Water Treatment Type of water 511

To evaluate GAC removal performance of PFAS, small-scale GAC column tests (municipal wastewater spiked with PFAS) were carried out. The experiments were developed to replicate real conditions, and to ascertain the efficiency of GAC at collecting PFAS in the water.

Significant removal of PFASs was achieved in the water after crossing the granular activated carbon water filter columns during the experiments. This suggests that GAC is a suitable treatment to eliminate PFAS in municipal wastewater as a measure to protect public health and the environment.

One of the major benefits of GAC for PFAS treatment is that it works quickly. GAC is the fast tool to adsorb PFAS in water treatment practice and is an approach to solve PFAS pollution.

We believe in the efficiency of GAC to decrease PFAS in water levels in a fast and efficient manner offering a fast solution for removal of such hazardous chemicals. This quick look at GAC performance may indicate it as a candidate for implementation in municipal waste water treatment plants to safeguard water quality and public health.

Application of GAC to PFAS Contamination

PFAS pollution is an issue increasingly facing communities globally. Such toxic substances are resistant in the environment and may bio-accumulate in water bodies, posing a threat to human health and ecosystem. With Granular Activated Carbon we can remove PFAS and keep our water systems safe.

Otherwisewe recommend the granular activated carbon, the purer the better.}; GAC is a economical insitu method to remove PFAS in wastewater so we have the safety and clean water source as well. By introducing GAC treatment into municipal wastewater facilities, we have prevented PFAS from discharging into our water and eliminated potential human health effects due to PFAS.

Research highlights successes of GAC for PFAS in wastewater

4 Conclusions Overall, our study shows a promising application of GACs for PFAS removal in MWTPs. GAC was effective at adsorption of PFAS in water, this study offered the straightforward and efficiency measure in treating water contaminated by PFAS.

As we performed small scale tests to evaluate the efficacy of granular activated carbon we could see that, GAC has rapid removal efficiency of PFAS from contaminated water. This demonstrates the value of GAC as an asset to municipal wastewater treatment plants concerned with safeguarding water quality and public health.

In summary, our findings highlight the urgent need to develop effective mitigation strategies for PFAS discharges to wastewater. We can protect our water supplies and clean up our environment for generations to come with Granular Activated Carbon.

Valves are critical components in a vast number of machinery and devices. They regulate the supply of liquids and gases, making sure that everything functions properly. Care and Maintenance Just as we take care of our toys or pets to keep them around a bit longer, so do valves require regular care and maintenance. If we take good care of valves, they will work fine for a long time.

Realising the Value of Valve Maintenance

Valve maintenance is similar to taking a valve to the doctor to make sure it is functioning properly. If we neglect valve maintenance, the valve cannot function well or may be in trouble. This pneumatic valve actuator can mean big problems and could even prevent a machine from running. That’s why it’s important to regularly maintain valves in order to keep them operating at their best.

Tips for Properly Maintaining Valves

Valves have basic maintenance to help ensure they last a lifetime. One that bears noting is to maintain the cleanliness of valves, so that dirt and other particles are removed from its surface before it has time to accumulate and become problematic. Another suggestion was to listen for leaks or odd sounds which could indicate the valve was not functioning correctly. Let’s follow these advices so we can preserve our valves in a good way.

Make Your Valves Last Longer with Some TLC

Valve durability is directly tied to the routine care it receives. With timely valve checks and repairs, we could avoid having bigger problems in the future. It can help save time and money in the long run, while also ensuring that machines continue to operate smoothly. Caring for actuator pneumatic valve up front can be a big difference in the end.

The position of scheduled sevalveperating and maintenance across all valve types.

Maintenance is a big factor in the operation of valves. Valves operate economically and efficiently if they are maintained in good condition. That’s what keeps machines running and prevents them from breaking down. By keeping up with maintenance, we can keep the valves doing what they are designed to do…and that’s keep things moving.

Strategies for Extending the Service Life of Valves

But there are massive methods that can be utilized to extend the service life of valves. One approach is to do as the manufacturer recommends in terms of maintenance and use. These recommendations provide us important information about the proper care for the valves. Another approach is to develop a maintenance plan and follow it. If we check and maintain valves on a schedule, we can make them last longer and work more efficiently.

All in all, if you want to keep the machine working fine, it needs the valve special nursing. And if we learn to actuator valve pneumatic maintenance of the valves, follow up caring tips and really keep an eye on the valves, we will make them last longer. One of the key factors for valve performance is in its maintenance, add up some strategic measures for Valve long-service life and you will find that valves will survive at its maximum stage. By following these steps, we can ensure that valves remain in good working condition and fulfill their functions over time.” So, you know, good maintenance and caring for your valves is definitely the key to a longer-lasting valve. And remember, here at SHTMF, we're concerned with the durability and smooth function of your valves.

Whilst indeed solid tube ice and normal tube ice might seem very much alike on the outside, they are in fact quite different from one another. So without further ado, let’s dissect the differences.

Solid tube ice are two kinds of regular tube ice, of which some tube ice is one require.

Ingredients make a big difference “If you’re looking at the ice that’s actually being made, the stuff that’s forming then the typical factors that determine the characteristics of the ice are going to be the composition,” Pomeroy said. Tube ice machine price is usually manufactured by a process utilizing purified and filtered water that is frozen and is formed into a shaped like a tube by the tubes. Meanwhile, regular tube ice can be in the presence of additives or impurities which affects the purity of the ice and its taste.

Investigation of the effects of freezing process on the texture of solid tube ice in comparison to regular tube ice.

The texture of the ice is also influenced by the freezing technique. Why we need solid tube ice Because solid tube ice is frozen at a lower temperature for longer time and the resulting ice cube is harder and stronger. Standard tube ice is rapidly frozen at higher temperatures and can therefore have a soft and porous texture.

Comparison in size and shape variations between solid tube ice and normal tube ice.

There can be differences in size and shape between solid tube ice and standard tube ice. Solid Cylindrical Tube Ice Solid cylindrical tube ice machine is generally larger and more uniform in shape, and is better suited to certain applications such as cooling beverages or preserving food. Conventional tube ice, meanwhile, can be delivered in smaller dimensions or irregular shapes, making it less versatile for some purposes.

Realizing the special applications and advantages of solid tube ice having over the normal tube ice.

Solid tube ice has its own special uses and advantages that are different from regular tube ice. Solid tube ice, with its dense, solid makeup is great for long lasting cooling and you can even use it for medical applications like reducing fevers and applying to injuries. lab picTube ice is still a great ice for most applications but it is not as beneficial for some as the above.

Comparing solid tube ice melting rates against regular tube ice and how it applies to different use cases.

The melting speed Solid Tube Ice VS Regular Tube Ice Something that differentiates solid tube ice and regular tube is their melting speed. Solid tube ice can also melt more slowly than regular tube ice, which can be useful when longer-term cooling is required, for example, in transportation or storage. Standard tube ice, however, could melt faster, so it may be better served for immediate cooling purposes, such as for beverages or cocktails.

To sum up, although industrial tube ice machine in solid, and regular tube ice may look similar, but they are in fact totally different in ingredients, texture, size, shapes, applications and melting speeds. Knowing these differences can help you determine which type of ice is right for your application. If you need commercial ice from tubes and hollow cubes, used with carbonated drinks and ice storage It can also be used for ice tube making machines of medical system, Icemedal Refrigeration Equipment offers ivergent options in ice types in ivergent forms to accommodate your demand.

What nozzles does the Craftop 3-in-1 sprayer have and what spraying situations are suitable for it?

By traspino, 2025-08-10

With the CRAFTOP 3-in-1 sprayer, there are different types of nozzles to allow you to do so. These nozzles assist you in various spraying activities that you could be having. Knowing which nozzle to use for each job is important so that you can get the best result.

Nozzle options for spraying different materials; For multiple applications

The CRAFTOP 3-in-1 sprayer has three nozzles. Nozzles have specific usages so choosing the right one for what you need is crucial. The first is a fan nozzle, which dissipates the spray in a broad pattern. It’s great for coverage over a large area. The second nozzle is a cone shaped nozzle which fans out in a circular shape. For smaller areas and more targeted spraying, this is good. The final nozzle is an adjustable nozzle, allowing you to easily adjust the mist to a powerful stream.

Reviews for CRAFTOP 3-IN-1 Sprayer nozzle options Here are the different nozzle options of the sprayer:

To get the most from your CRAFTOP 3-IN-1 sprayer, it’s essential to know the various nozzle choices. The fan nozzle is the best for spraying things like fences or walls, that you need to cover a lot of surface area. Save that one for flowers or plants, where you’ll want to be more accurate with your spraying. What type of spray you want determines its performance, and the nozzle can be adjusted to suit all sorts of tasks.

Optimal spraying environments for each of the CRAFTOP 3-in-i nozzles

When operating the CRAFTOP 3-in-1 10L sprayer , you need to know how to apply each nozzle. For instance, if you are spraying your garden plants, the cone nozzle is the most appropriate. The fan nozzle would be good if your spraying the fence a substantial length. And if you’re not quite sure which nozzle you’ll need, one that’s adjustable might be a great all-around option.

Choosing the Suitable Spraying Nozzle for your Spraying Application

In order to get the best results with your CRAFTOP 3 in 1 sprayer you’ll need to the right nozzle for your job. Consider what it is you are trying to spray and then consider how you’d like the spray to appear. For a larger area, go with the fan nozzle. If you want more of a precision application, opt for the cone nozzle. And if you require flexibility, an adjustable nozzle is worth considering.

With the right tip for every job, the performance of your CRAFTOP 3-in-1 15L sprayer can now be maximized. That, in turn, means better results for you, and saved time and effort. Do some experimenting on your own to determine which nozzle is best for you and your particular spraying application. With an appropriate one, you can easily accomplish any spraying job swiftly and more efficiently.