@traspino

- Followers 0

- Following 0

- Updates 338

How to Choose Between API 610 and API 685 Pumps for Your Application

API 610 pumps and API 685 pumps may sound super big and super fancy to regular folk, but in reality, they are just types of pumps that are utilized and applied in different industries for purposes specific to that particular field. When considering which pump is right for your application, it is crucial to understand the differences between these two styles along with your system's requirements.

Knowing the distinctions between API 610 and API 685 pumps:

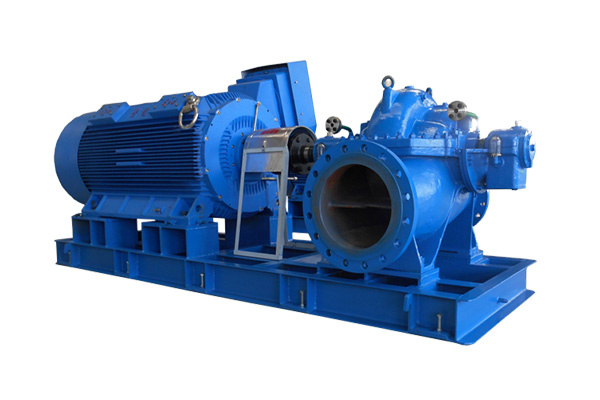

Api 610 pump serve industry around the world, including oil and gas, petrochemical and refineries, for offshore and onshore applications. They're versatile, dependable and have one of the most popular amplitudes for all-blade tasks.

Conversely, API 685 pumps are intended for use with dangerous or toxic fluids, which are common to industries like chemical processing and pharmaceuticals. These pumps are designed and manufactured to the highest safety measures to keep both the operators and our precious nature safe.

What to consider before choosing between API 610 vs API 685 pumps:

When deciding whether to use an API 610 BB2 horizontal split multistage pump or an API 685 pump, you need to take into account the demands of your application. Factors to take into account include the nature of the fluid being pumped, operating conditions, the degree of safety needed and the cost of the pump.

API 610 vs API 685 Both speed and size of pump will be a matter of co.

API 610 Pumps are even one of the best performance pumped valves and in other words, widely used across various industries. These pumps are suitable for a variety of fluids and operating conditions, making them ideal for many industries.

API 685 Types API 685 pumps, however, are dedicated to dangerous or hazardous fluids. Constructed to stringent safety standards for safe and reliable performance, these pumps support both workers and the environment- the kind of protection that makes them a good choice for applications that involve handling hazardous materials.

Why the correct choice of pump will make or break your application:

It is essential to select the best pumping system for your needs to prevent inefficient and unsafe operations. The incorrect pump will can cause expensive downtime, unsafe conditions, and further environmental issues.

Decision support in the selection of API 610 vs API 685 pumps:

When deciding between api 610 and API 685 pumps, be sure to take a close look at your specific requirements and consult a pump expert for guidance. By researching these 2 types of pumps and keeping a few things in mind, you can make sure that you are getting the right pump for you.

In summary It’s a big decision to choose approach between an API 610 pump and an API 685 pump but knowing the differences between these two types of pump and knowing the unique requirements of the application will make the decision-making easier and in that way you can ensure the efficiency and safety of your operations. And, as always, if you’re not sure what pump is best for your application, consult a pump expert to assist with your selection.