@pink143

- Followers 0

- Following 0

- Updates 472

Blog

Mobile High Pressure Hose Reels are a must-have for on-site industrial maintenance tasks. These reels provide a convenient and efficient solution for handling high-pressure hoses in various industrial settings. Whether you need to clean equipment, wash down surfaces, or perform other maintenance tasks, Yongye's Mobile High Pressure Hose Reels are designed to meet your needs with ease and effectiveness.

The Ultimate Solution for On-Site Industrial Maintenance:

Yongye's Mobile High Pressure Hose Reels offer the ultimate solution for on-site industrial maintenance tasks. These reels are designed to be portable and easy to maneuver, allowing you to take them wherever you need to work. With their high-pressure capabilities, you can easily clean, wash, or lubricate equipment and surfaces in a variety of industrial settings. Whether you are working in a factory, construction site, or other industrial environment, these hose reels provide a reliable and efficient solution for all your maintenance needs.

Discover the Top Quality Mobile High Pressure Hose Reels:

Yongye's Mobile High Pressure Hose Reels stand out for their top-quality construction and design. These reels are built to last, with durable materials that can withstand the rigors of industrial use. The high-pressure hoses are designed to handle a variety of cleaning and maintenance tasks, ensuring that you can get the job done quickly and effectively. With Yongye's Mobile High Pressure Hose Reels, you can trust that you are getting a reliable and high-quality product that will meet your industrial maintenance needs for years to come.

Why Mobile High Pressure Hose Reels are Essential for Industrial Maintenance

Industrial maintenance involves a lot of hard work, from cleaning to repairing machines and equipment. One important tool that can make these tasks easier is a mobile high pressure hose reel. These hose reels are essential because they allow workers to easily access water or other cleaning solutions at high pressure, making it easier to clean stubborn dirt and grime. With the ability to move around easily, workers can reach all areas of the industrial site without any hassle. This not only saves time but also ensures that the maintenance work is done efficiently.

How to Choose the Best Mobile High Pressure Hose Reels for Wholesale

When looking for power washer hose reel the best mobile high pressure hose reels for wholesale, there are a few key factors to consider. First, it's important to look for a reel that is durable and can withstand the demands of industrial maintenance work. The material of the reel should be strong and resistant to corrosion. Additionally, the hose length and pressure capacity should be suitable for the specific needs of the industrial site. It's also important to consider the mobility of the reel, ensuring that it is easy to move around and use in different areas of the site. By choosing a high-quality mobile hose reel, industrial pressure washer hose reel maintenance workers can ensure that their tasks are completed efficiently and effectively.

Common Issues with Industrial Maintenance and How Mobile High Pressure Hose Reels Can Help

Industrial maintenance can come with its own set of challenges, from hard-to-reach areas to stubborn dirt and grime. This is where mobile high pressure hose reels can come in handy. These hose reels provide workers with easy access to high-pressure water or cleaning solutions, making it easier to clean even the toughest stains. By using a mobile hose reel, workers pressure washer hose and reel can save time and effort, ensuring that maintenance tasks are completed quickly and effectively. Additionally, the mobility of the hose reel allows workers to reach all areas of the industrial site, ensuring that no spot is missed during the cleaning process. Overall, mobile high pressure hose reels are a valuable tool for industrial maintenance workers looking to make their tasks easier and more efficient.

Custom High Pressure Hose Reels for Specialized Industrial Applications (e.g., Auto Assembly)

By pink143, 2025-11-14

Custom high-pressure hose reels play a crucial role in specialized industrial applications, such as auto assembly. These reels are designed to withstand high pressures and provide efficient solutions for various industries. Let's explore the importance of custom high-pressure hose reels in specialized industrial applications and why they are essential for auto assembly.

Specialized Industrial Applications for Custom High Pressure Hose Reels:

Custom high-pressure hose reels are tailored to meet the specific needs of various industries, including auto assembly, manufacturing, and construction. These reels are designed to handle high-pressure fluids, such as water, oil, and chemicals, ensuring safe and efficient operations. For example, in auto assembly plants, custom high-pressure hose reels are used for lubricating machinery, cleaning parts, and maintaining equipment. These reels are built to withstand harsh industrial environments and provide reliable performance to keep operations running smoothly.

Why are Custom High Pressure Hose Reels essential for Auto Assembly?

In the auto assembly industry, custom high-pressure hose reels are essential for ensuring the smooth operation of production lines. These reels are used for a variety of applications, such as spraying lubricants, cleaning parts, and providing hydraulic power to machines. Without custom high-pressure hose reels, auto assembly plants would face challenges in maintaining equipment, ensuring worker safety, and meeting production deadlines. These specialized reels help streamline operations, reduce downtime, and improve efficiency in auto assembly plants. By investing in custom high-pressure hose reels, auto assembly plants can enhance productivity, reduce maintenance costs, and improve overall operational performance.

When it comes to choosing the right Custom High Pressure Hose Reels for your industrial needs, there are a few key factors to consider. First and foremost, you'll want to think about the specific requirements of your application. For example, if you're working in an auto assembly power washer hose reel plant, you may need a hose reel that can handle high pressure and is durable enough to withstand frequent use. Additionally, you'll want to consider the size and weight of the hose reel, as well as any special features that may be necessary for your particular application. By taking the time to carefully assess your needs, you can ensure that you choose a hose reel that will meet your requirements and provide reliable performance.

When it comes to purchasing Custom High Pressure Hose Reels for your industrial needs, wholesale options can be a cost-effective solution. Buying in bulk can often result in significant savings, allowing you to get the equipment you need at a lower price. Additionally, purchasing wholesale can also provide you with pressure washer hose reel access to a wider range of options, ensuring that you can find the perfect hose reel for your application. By exploring wholesale options, you can save money and get the equipment you need to keep your operation running smoothly.

In terms of top trending features in Custom High Pressure Hose Reels for industrial use, there are a few key characteristics to keep an eye out for. One popular feature is automatic retraction, which allows the hose reel to retract smoothly and easily after use. This can help to prevent tangles and ensure that the hose is always stored neatly and securely. Another trending feature is adjustable tension control, which allows you to customize the amount of resistance when pulling out the hose. This pressure washer hose and reel can be particularly useful in applications where precise control is necessary. Additionally, features such as corrosion-resistant materials and high-pressure ratings are also important considerations when choosing a hose reel for industrial use. By selecting a hose reel with these top trending features, you can ensure that you get a durable, reliable, and efficient solution for your specialized industrial application.

Garage doors are more than just big doors on a home or building. They must work well and be safe. This is why the parts that make up garage doors, called hardware, need to follow certain rules. These rules help make sure the doors last long and don’t break easily. ASTM is a group that creates these rules to keep hardware strong and safe. At kuntai, we know how important it is to use hardware that meets these rules because it protects people and buildings. Let’s talk about the ASTM rules that guide garage door hardware and why they matter so much for buyers and sellers.

What ASTM Standards Are Essential for Wholesale Garage Door Hardware Buyers

When buying garage door hardware in large amounts, it’s important to know which ASTM rules apply. These rules focus on safety, strength, and quality. For example, ASTM F2200 is a key rule that covers rolling steel doors and their parts. This includes hinges, brackets, and rollers. It tells buyers what tests the hardware must pass to be safe. Some tests check if the metal parts are strong enough to hold the door’s weight without bending. Other tests make sure springs won’t snap and cause harm. Buyers need to look for hardware that follows these rules so they get parts that won’t fail quickly. At kuntai, we always check that our products meet ASTM standards before sending them out. This not only keeps the door working well but also protects users from accidents. Imagine if a garage door spring breaks suddenly; it can be dangerous. ASTM rules help stop this from happening by requiring strict testing. Wholesale buyers should also know that ASTM covers the materials used, like steel or aluminum. Hardware must resist rust and wear because garage doors face weather every day. When buyers choose ASTM-approved products, they get peace of mind knowing the hardware was tested many times. This saves money on repairs and keeps customers happy. Kuntai believes that following ASTM standards is part of being a professional company. It shows respect for safety and quality. Without these rules, buyers might get cheap, weak parts that don’t last. So, knowing and choosing ASTM-approved hardware makes a big difference in the long run.

What Wholesale Garage Door Hardware Needs to Comply with ASTM Regulations

Wholesale garage door hardware must follow many ASTM rules to be sold and used safely. One important part is durability. Hardware like hinges and tracks must not break after opening and closing the door thousands of times. ASTM tests make sure parts can handle this kind of use. For example, hardware is put through “cycle testing,” where it moves back and forth many times. If it breaks too soon, it fails the test and can’t be sold. This is very important because garage doors are used daily. Another rule covers how hardware fits together. ASTM says parts must fit correctly so the door works smoothly and doesn’t get stuck. If parts don’t fit well, the door might fall or stop working. Kuntai always checks the size and shape of parts to avoid this problem. Safety is a big part of ASTM rules too. For example, cables and springs must have protection so they don’t snap and hurt people. Some hardware also needs to meet fire resistance rules for places where safety is extra critical. Materials must be tested for rust resistance because garage doors face rain, snow, and sun. ASTM requires hardware to last in these tough conditions. Wholesale sellers must keep records that hardware meets these rules. This helps prove that products are safe and legal. If hardware doesn’t meet ASTM rules, it risks being banned from sale. That can make big problems for sellers. Kuntai’s team works hard to meet every ASTM requirement before shipping products. We believe this hard work keeps our customers safe and satisfied. It also helps build trust because buyers know they are getting quality. Meeting ASTM regulations is not only about rules; it’s about caring for people who use garage doors every day. Without these rules, hardware can fail, causing damage and injuries. That’s why we take ASTM compliance seriously and always push for the best.

What Common ASTM Standards Govern Durability of Garage Door Components

When we talk about garage doors, we want them to last a long time and work well every day. This is why there are special rules called ASTM standards. ASTM stands for the American Society for Testing and Materials. These rules help make sure that the parts of a garage door, like springs, rollers, and tracks, are strong and can stand up to daily use. For example, ASTM standards set tests to check if the springs can open and close the door many times without breaking. They also look at how well rollers move smoothly on tracks, even after a lot of use. At kuntai, we follow these important ASTM rules closely. This helps us create garage door hardware that does not wear out quickly. The standards also cover how metals and other materials used in the door parts resist rust and damage from weather. This means that garage doors made with ASTM-approved parts can handle rain, wind, and sun without falling apart. By using ASTM standards, kuntai ensures that our garage door hardware is safe and lasts for years. This is very important because garage doors are used every day in homes and businesses. When the door parts are strong and durable, people do not have to fix or replace them often, which saves money and keeps everyone safe. So, ASTM standards are like a promise that the garage door hardware you get from kuntai will be tough, reliable, and ready to work well for a long time.

How ASTM Compliance Affects Wholesale Garage Door Hardware Pricing and Value

When buying garage door hardware in large amounts, like for stores or builders, price and value are very important. ASTM compliance means that the products meet the strict rules set by the ASTM organization. This compliance can affect the price and value of the hardware in several ways. First, products that follow ASTM standards often cost a bit more to make because they require better materials and extra testing. At kuntai, we make sure all our garage door parts meet these rules. This means our customers get high-quality products that work well and last longer. While the initial price might be higher, the value is greater because the parts do not break or wear out quickly. This saves money in the long run because replacements and repairs happen less often. Also, buyers trust ASTM-compliant products more. When companies garage door assembly like kuntai sell hardware that meets these standards, customers feel confident they are getting good products. This trust can help sellers sell more and keep customers happy. In wholesale markets, ASTM compliance can make hardware stand out from cheaper, lower-quality options. It shows that the hardware is tested for safety, strength, and durability. This can make a big difference when people choose which products to buy. So, while ASTM compliance might raise the price a little, it also adds value by offering better performance and longer life. For kuntai and its customers, this balance is very important. It ensures that the garage door hardware bought in bulk is both affordable and top quality, making it a smart choice for anyone needing many parts.

What Are the Key ASTM Testing Requirements for Garage Door Hardware

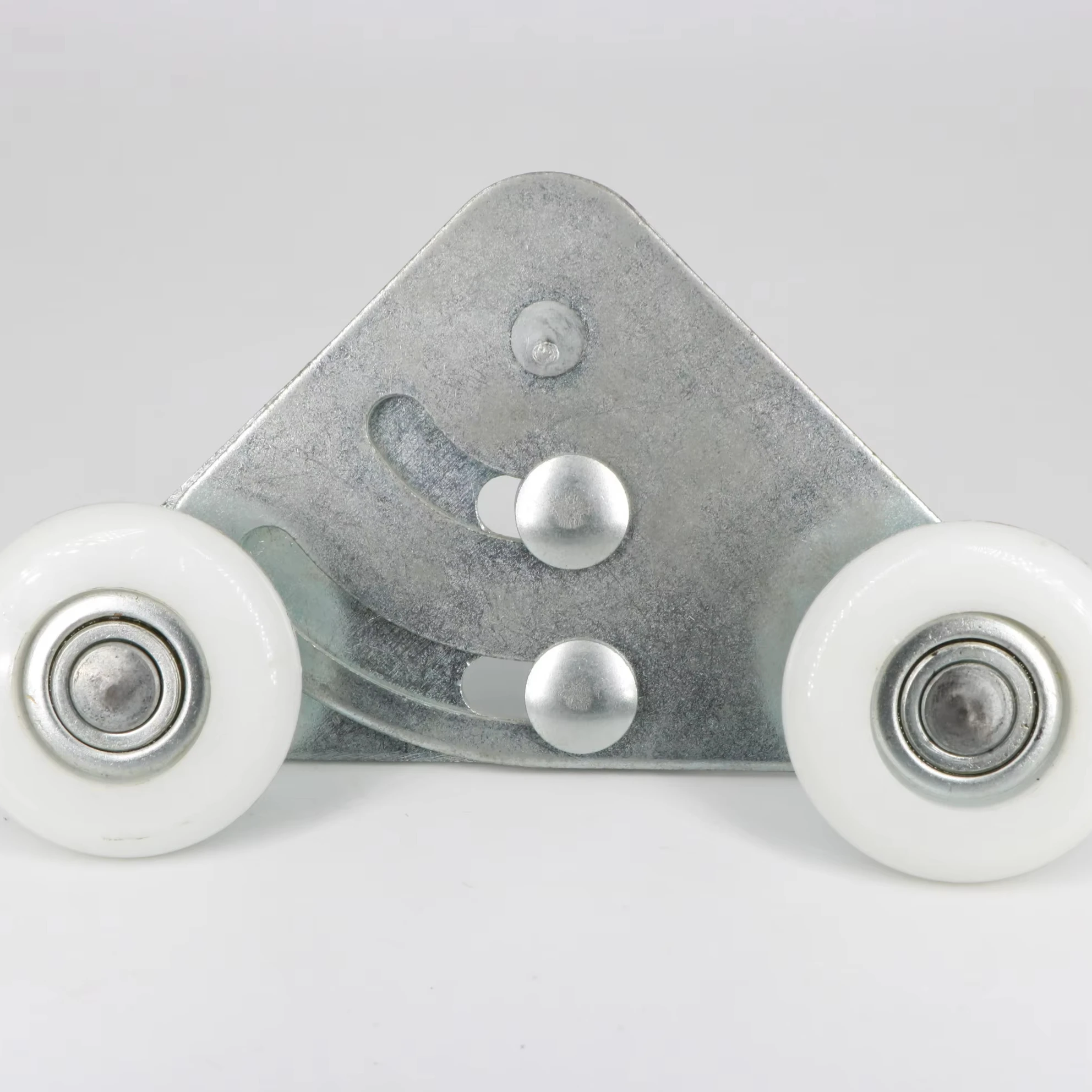

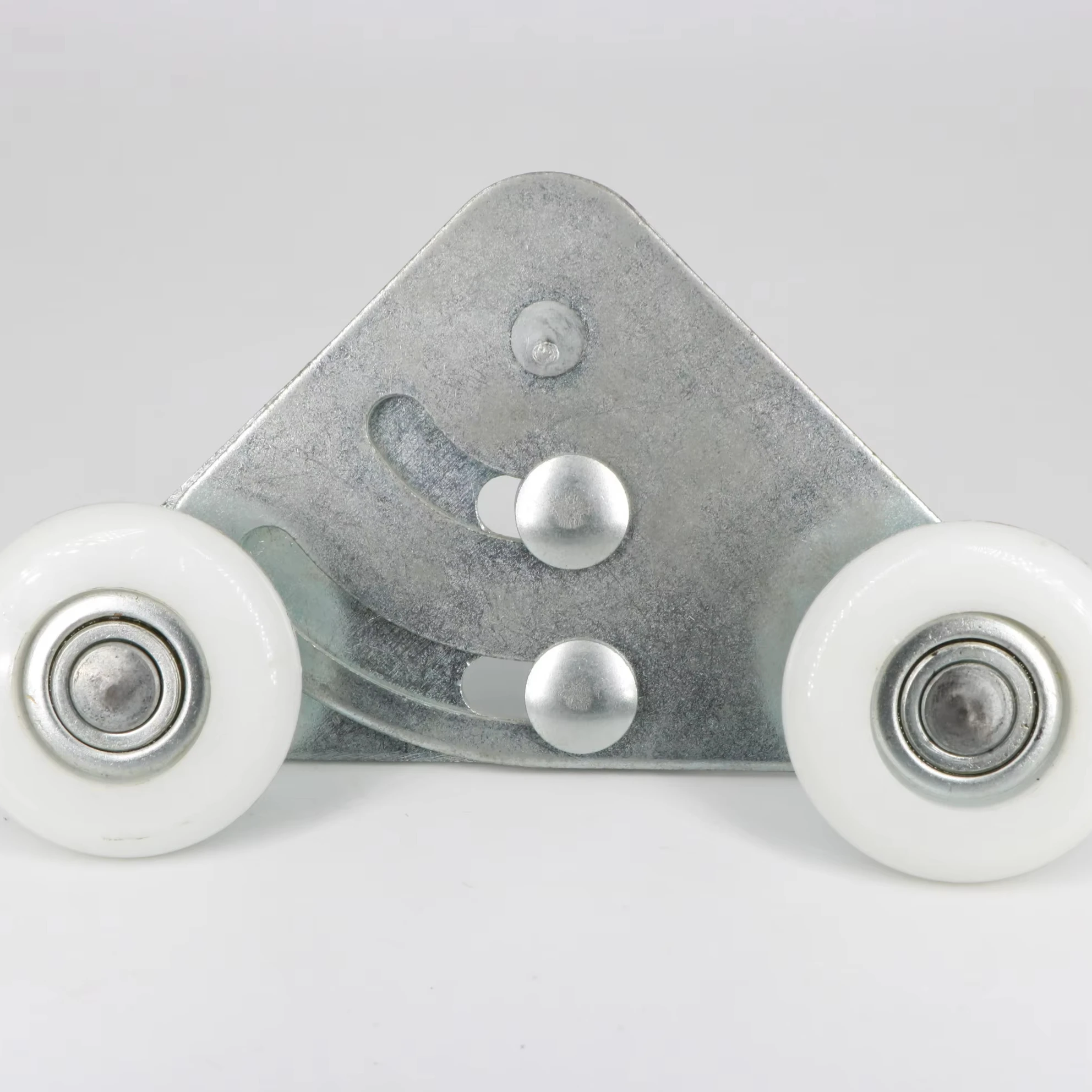

ASTM has many testing rules to make sure garage door roller assembly garage door hardware works safely and well. These tests check different parts like springs, hinges, and rollers to see how strong and reliable they are. One key test is the cycle test. This test opens and closes the garage door many times to see if parts like springs and rollers can handle everyday use. If they break or stop working well during the test, they do not meet ASTM standards. Another important test is the load test. This checks how much weight the parts can hold without bending or breaking. Garage doors are heavy, so hardware must be strong enough to support their weight safely. ASTM also requires corrosion resistance tests. These tests expose metal parts to salty or wet conditions to see if they will rust or weaken over time. Rust can make parts unsafe and cause the door to stop working. At kuntai, we carefully follow all these testing rules. Our hardware goes through tough cycle, load, and corrosion tests before it leaves our factory. There are also safety tests to make sure the hardware will not cause accidents. For example, some tests check if springs release energy safely to avoid hurting a garage door nylon roller people during repairs. ASTM standards require all these tests to protect users and make sure garage doors open and close smoothly for many years. By meeting these key testing requirements, kuntai guarantees that our garage door hardware is safe, strong, and built to last. This gives customers peace of mind knowing their garage doors will work properly and safely every day. Following ASTM testing is one of the most important ways we ensure quality and safety in every part we make.

Sectional doors are made up of several panels connected by hinges. When these doors open or close, they move along tracks that sometimes curve. The hinges between the panels must work just right so the door follows those curves without getting stuck or damaged. At kuntai, we know how important it is for these hinges to be strong and flexible. They let the door bend and turn smoothly along the curved tracks. Without the right hinges, the door would be hard to operate and might break. So, hinges are a key part that helps sectional doors work well, especially when the tracks are not straight.

How Sectional Door Hinges Enable Smooth Track Curve Navigation

Sectional door hinges are special because they allow each panel to move independently while still connected. Imagine the door as a chain of small pieces joined together. When the track curves, each panel needs to turn a bit to follow the path. The hinges at each joint let the panels bend in different directions. This flexibility is what makes it possible for the door to smoothly “slide” along curved tracks. If the hinges were stiff or fixed, the door would not be able to follow the curve and might get stuck or cause damage. At kuntai, we design hinges that move easily but still hold the panels tightly. The hinges have pins and plates that rotate and slide, giving the door the right amount of movement. Sometimes the hinges also have rollers or bearings to reduce friction. This helps the door open and close quietly and with less effort. A good hinge must handle the weight of the door panels while letting them twist and turn. When installed properly on curved tracks, these hinges help the door maintain its shape and avoid gaps or misalignments. For example, if a garage door has a gentle curve in its track, each hinge will rotate slightly to fit that curve. If the curve is sharper, the hinges can bend more, adjusting the angle between panels. This way, the door follows the track perfectly without extra stress on the parts. The design of sectional door hinges means they can work on many different types of curves, whether wide or tight. At kuntai, we test our hinges in many conditions to make sure they last long and perform well. This means fewer repairs and happier customers who can rely on their doors day after day.

What Makes Sectional Door Hinges Ideal for Curved Track Applications

Sectional door hinges are ideal for curved tracks because they combine strength, flexibility, and durability. These hinges are made from strong materials like steel that will not bend or break easily. At the same time, they are built to allow smooth movement between panels. This balance is hard to achieve but crucial for curved track doors. If the hinge is too soft, it may wear out quickly or become loose. If it is too rigid, it won’t allow the door to bend properly along the curve. Kuntai’s expertise lies in creating hinges that meet these needs perfectly. We pay close attention to the shape and size of the hinge parts, making sure the pins fit tightly but still rotate freely. The hinges are coated to resist rust and corrosion, which is important because doors often face weather changes. Another important feature is how the hinges connect to the panels and the door frame. They must be easy to install and adjust, so the door fits the track well. Our hinges come with mounting holes and guides that help installers align everything exactly right. When the door moves, the hinges spread the force evenly across all panels. This prevents any single part from bearing too much load, which can cause damage. For curved tracks, this even force distribution is key to keeping the door running smoothly for years. Also, sectional door hinges reduce noise and vibration during operation. This makes the door less annoying to use and helps protect the whole mechanism. By choosing hinges like those from kuntai, customers get a product that is made to handle the challenges of curved tracks. These hinges bring comfort and reliability to doors that must move in more complex ways than straight doors. Because of this, sectional door hinges are the best choice when your door needs to work on a curved path, whether in homes, warehouses, or factories.

Where to Find Wholesale Sectional Door Hinges for Curved Tracks

If you are looking to buy sectional door hinges that work well with curved tracks, finding the right place to get them is very important. At kuntai, we offer a wide range of wholesale sectional door hinges designed especially for doors that follow curved tracks. Buying wholesale means you can get many hinges at a lower price, which is great if you have several doors or want to keep extra parts for the future. When searching for hinges, it is important to find a supplier who knows about curved tracks and how hinges should work with them. Kuntai’s hinges are made to fit smoothly on curved tracks, which helps the door open and close easily without getting stuck or making noise.

You can find wholesale sectional door hinges from kuntai either by visiting our website or contacting our sales team. We provide detailed information about the different types of hinges that fit various track curves. Whether your track curves gently or sharply, kuntai has hinges that can handle those shapes. Since curved tracks need hinges that can bend and move correctly, buying from a company like kuntai ensures you get strong and reliable parts. Our hinges are tested for quality and designed to last a long time, even with daily use. If you want to save money and get quality hinges that fit curved tracks well, buying from kuntai wholesale is a smart choice.

Besides selling good hinges, kuntai also helps customers by answering questions and giving advice on how to install the hinges on curved tracks. This support can be very helpful if you are new to sectional doors or if the door track has a tricky curve. So, if you need sectional door hinges for curved tracks, buying wholesale from kuntai is easy, affordable, and reliable. This will help your doors work better and last longer.

How to Choose Sectional Door Hinges That Perfectly Fit Track Curves

Choosing the right sectional door hinges for curved tracks is very important because the hinges help the door follow the track smoothly. At kuntai, we understand that not all hinges are the same. When you pick hinges, you need to think about the shape and size of the curve in your door track. Some curves are gentle and wide, while others are tight and sharp. Hinges from kuntai come in different designs to fit these different curves, making sure that the door moves easily and does not get stuck.

First, look at how much the track bends. If the curve is small, you will need hinges that can bend sharply without breaking or making the door hard to move. Kuntai makes strong hinges with special joints that allow bending in tight spaces. For wider curves, you might need hinges that can hold the door firmly while still giving it some flexibility. Kuntai offers these kinds of hinges too, so you can pick the best fit.

Second, consider the weight of your door. Heavy doors need stronger hinges. Kuntai’s sectional door hinges are made from tough metal that can handle heavy doors without bending or wearing out quickly. This helps keep your door safe and working well for a long time.

Third, think about how easy it is to install the hinges. Kuntai designs hinges that are simple to attach to your door and track. This saves time and makes sure the door fits perfectly on the curved track.

Lastly, check if the hinges come with extra features like rust resistance or lubrication. These features help the hinges last longer and work smoothly. Kuntai’s hinges often include these helpful features.

By choosing the right sectional door hinge from kuntai that matches your track curve, door weight, and installation needs, you make sure your door opens and closes with no problems. This keeps your home or building safe and your door working well every day.

Troubleshooting Common Problems with Sectional Door Hinges on Curved Tracks

Even though sectional door hinges from kuntai are made to work well on curved tracks, sometimes problems can happen. Knowing how to fix common issues can help your door stay in good shape and last longer. Here are some easy tips to troubleshoot problems with sectional door hinges on curved tracks.

One common problem is that the door gets stuck or does not move smoothly along the curved track. This can happen if the hinges are not the right size or if they are loose. Check the hinges to see if they fit the curve properly. If they look bent or worn out, you might need to replace them with garage door assembly new kuntai hinges that match your track curve better. Also, make sure all screws and bolts holding the hinges are tight. Loose parts can make the door hard to move.

Another problem is noise when opening or closing the door. This can be caused by dry or rusty hinges. Kuntai’s sectional door hinges come with good materials that resist rust, but if your hinges get dirty or dry, you can use some lubricant on the moving parts. This helps the door move quietly and smoothly.

Sometimes, the door might not line up right on the curved track. This garage door roller assembly can happen if the hinges are installed too high or too low. Check the position of the hinges and adjust them if needed. Kuntai provides clear instructions to help place the hinges correctly, so following those steps can fix this problem.

If the hinges get damaged or bent, it is best to replace them quickly. Using broken hinges can cause bigger problems for your door and track. Buying replacement hinges from kuntai ensures you get parts that fit your curved track perfectly.

By understanding these common problems and how to fix them using kuntai sectional door hinges, you garage door nylon roller can keep your door working well and avoid costly repairs. Regular care and checking your hinges help your door open and close smoothly every day.

Garage doors might seem simple, but they have many parts working together to keep them safe and strong. One very important part is the metal brackets. These small pieces of metal do more than just hold things in place. They help share the weight of the garage door evenly. Without these brackets, the door could become weak or even break. At kuntai, we make sure our metal brackets are tough and reliable so your garage door works smoothly and lasts a long time. Understanding how these brackets work can help you see why they matter so much.

What Are Garage Door Metal Brackets and Their Importance in Load Distribution

Garage door metal brackets are strong metal pieces that connect different parts of the garage door. They are usually made of steel or another heavy metal. These brackets hold the door panels, tracks, springs, and other parts firmly together. The most important job of these brackets is to spread the weight or load of the garage door evenly. When you open or close the door, a lot of force and pressure happens. If the brackets were weak or missing, all that pressure would fall on just one spot. This could cause the door to bend, get stuck, or even fall down. Imagine trying to carry a heavy box with one hand—it's hard and unsafe. But if you use both hands, the weight feels lighter and easier to carry. The brackets work like those two hands, sharing the door’s weight so no single part gets too tired or breaks. At kuntai, we design our metal brackets with special care. We test them to handle different weights and pressures. For example, some garage doors are very big and heavy, like those in warehouses or big shops. Our brackets can handle those heavy loads without bending or breaking. Small home garage doors also need strong brackets because even a small failure can cause big problems. Besides just holding weight, these brackets help the door move smoothly. They keep the parts lined up so the door doesn’t wobble or get stuck. If the brackets are not strong enough, you might hear creaking noises or see the door shake when it opens or closes. That’s a sign the brackets are struggling. From my experience working at kuntai, I have seen many cases where replacing old, weak brackets with our strong metal ones makes a huge difference. The door works quieter, smoother, and feels safer. So, metal brackets are not just small pieces of metal—they are the hidden heroes that keep your garage door strong and balanced.

Where to Find High-Quality Garage Door Metal Brackets for Wholesale Purchase

Finding good metal brackets for garage doors can be tricky if you don’t know where to look. Many places sell brackets, but not all are made well. Some might look strong but break fast. Others might not fit right, causing more problems than they solve. If you want brackets that last and work perfectly, you need to find a trusted supplier. At kuntai, we offer high-quality garage door metal brackets made with care and tested to meet tough demands. Buying from us means you get brackets made from strong metals, with exact shapes and sizes. This makes installation easier and the door safer. We sell our brackets in large quantities for businesses or installers who need many parts at once. Wholesale buying from kuntai saves money because you pay less for more pieces. Also, we ship fast so you don’t wait long before your project can start. Our team knows that every customer has different needs. Some want brackets for small homes; others need heavy-duty brackets for big doors. We help each customer find the right bracket for their garage door type and size. We also provide advice on how to install them properly. During my time with kuntai, I have talked with many customers who were happy they chose us. They tell me our brackets last longer and make their garage doors safer. Some even say their business runs smoother because they don’t have to fix broken brackets all the time. So, if you need strong metal brackets that do their job well, kuntai is a good place to start. You get quality, support, and fair prices all in one. Don’t settle for less when it comes to safety and strength. Choose brackets that make a difference.

Common Issues with Garage Door Metal Brackets and How They Affect Load Distribution

Garage door metal brackets are very important parts of a garage door system. They help hold different pieces of the door together and make sure the weight of the door is spread out evenly. When these brackets have problems, it can cause big troubles with how the door works. One common issue is that the metal brackets can bend or break if they are weak or old. When a bracket bends, it cannot hold the door parts in the right place. This makes the door heavier on one side, causing uneven load distribution. Uneven load means some parts of the door carry more weight than they should. This can make the door hard to open or close and can wear out other parts faster.

Another problem is when the brackets get loose. Over time, screws and bolts can become loose because of the door moving up and down many times. Loose brackets don’t hold the door parts tightly. This also changes how the weight spreads across the door. If the load is not spread out correctly, it puts extra stress on the garage door opener and the springs. This can lead to these parts breaking sooner than they should. Sometimes, rust or dirt can build up on the metal brackets. Rust makes the metal weaker and can cause the bracket to crack. Dirt can stop the brackets from moving smoothly, which affects how the door works.

At kuntai, we understand how important strong and well-maintained metal brackets are for your garage door. If your garage door metal brackets have any of these problems, it’s important to fix or replace them quickly. This will help the door stay balanced and work safely. Good load distribution helps the door last longer and keeps your garage safe.

How to Select the Best Garage Door Metal Brackets for Heavy-Duty Load Support

Choosing the right metal brackets for a garage door is very important, especially if the door is heavy or used a lot. Heavy-duty load support means the brackets must be very strong and able to carry a lot of weight without bending or breaking. When selecting metal brackets, the first thing to look for is the material. Strong metals like steel are usually best because they can hold heavy loads and last a long time. At kuntai, we make sure our metal brackets are made from high-quality steel that can handle tough conditions.

The size and shape of the brackets also matter. Bigger brackets can spread the weight better, which helps keep the door balanced. The shape should fit well with the door parts so everything stays tight and secure. If the brackets don’t fit well, the load won’t be spread evenly, and the door might get damaged. Another important factor is the thickness of the metal. Thicker brackets are stronger and less likely to bend. However, very thick brackets may be heavier and harder to install, so it’s important to find the right balance.

Also, check the bracket’s design features. Some brackets come with extra support ribs or special coatings to prevent rust. These features help the brackets stay strong for a long time, even in bad weather. At kuntai, we design our metal brackets with these features to give you the best heavy-duty load support. When buying metal brackets, always ask about their weight capacity. This tells you how much weight the bracket can safely hold. Choosing brackets with a higher weight capacity than you need is a smart way to make sure your garage door stays safe and works well over time.

What Wholesale Buyers Need to Know About Garage Door Metal Bracket Materials

For wholesale buyers, knowing garage door roller assembly about the materials used in garage door metal brackets is very important. The material affects how strong and long-lasting the brackets will be. Most metal brackets are made from steel, but steel comes in different kinds. Some steel is stronger and resists rust better than others. At kuntai, we use high-grade steel for our brackets to make sure they can handle heavy loads and resist damage from weather. Choosing the right material means your customers will get a product that works well and lasts a long time.

Another material to think about is the coating on the metal brackets. Coatings like zinc or powder coatings protect the metal from rust and corrosion. Rust can make brackets weak and unsafe. Wholesale garage door nylon roller buyers should look for brackets with good coatings because they need to stay strong for many years, even in wet or humid places. At kuntai, all our metal brackets come with special coatings that keep them safe from rust and wear.

Buyers should also consider the manufacturing process. Metal brackets made with good techniques are more reliable. For example, brackets that are welded or stamped precisely will hold up better under heavy use. Poorly made brackets might have weak points that can break. Wholesale buyers want to choose suppliers like kuntai who focus on quality and strength garage nylon rollers in every bracket.

Finally, buyers should think about the variety of metal brackets offered. Having different sizes and styles helps meet the needs of many customers. Kuntai provides a wide range of brackets so wholesale buyers can offer the right product for any garage door. Knowing about materials, coatings, and quality helps wholesale buyers make smart choices and offer the best garage door metal brackets to their customers.

Garage panel door parts come in different weight classes because the weight of the door affects how the parts work together. Heavier doors need stronger and sometimes bigger parts to handle the extra stress, while lighter doors can use smaller or lighter parts. This is important because if the parts are not right for the weight, the door might not open or close properly, or it could even break faster. At kuntai, we carefully design our parts to match each weight class, helping doors last longer and work smoothly. Weight classes help make sure every part fits the door’s size and strength needs.

Common Issues When Selecting Garage Panel Door Parts Based on Weight Class

Sometimes people pick parts for garage doors just by guessing or copying what they used before, without thinking about the door’s weight class. This causes problems like parts wearing out fast or even breaking. For example, if a heavy door uses springs made for a light door, those springs will stretch or snap quickly because they aren’t strong enough. On the other hand, if a light door has parts made for heavy doors, the door may feel too stiff or hard to open. Another issue is that some parts might not fit well if they don’t match the door’s weight, causing the door to get stuck or make noise. This happens a lot with rollers and hinges that are not built for the door’s weight. Also, people sometimes forget that garage doors move a lot during the day. If parts are not matched to the weight, they can get damaged sooner than expected. From what I have seen working with kuntai, one of the biggest mistakes is ignoring the door’s weight when ordering parts in bulk. This leads to returns and delays, which costs time and money. So, knowing the correct weight class and using parts designed for it prevents many headaches and keeps the doors running smooth for years.

How to Choose the Right Weight Class for Garage Panel Door Parts in Large Orders

When ordering a lot of garage panel door parts, it’s very important to pick the right weight class for each part. First, you must check the weight of the doors you are working with. This might mean weighing a door or checking the manufacturer’s specs. At kuntai, we recommend sorting doors into groups by weight before choosing parts. This helps avoid mixing up parts made for different weights. Next, look at the parts’ specifications carefully. Heavy doors need springs with more strength and cables that can hold more weight. Rollers and hinges should also be stronger and sometimes larger. For lighter doors, parts can be smaller or lighter, which saves money and makes the door easier to use. Another thing to watch for is the quality of the parts. Even if they match the weight, cheaper parts might fail faster. Kuntai parts are made with good materials to handle their weight class well and last longer. When placing large orders, it’s smart to ask for advice or samples before buying everything. This lets you check if the parts work well with your doors. Also, keep records of each weight class and part type you order. This helps track what works best and avoids mistakes in the future. From my experience, careful planning and choosing the right weight class saves time, reduces problems, and keeps customers happy.

Where Weight Class Impacts Garage Panel Door Parts Shipping and Cost Efficiency

When we talk about garage panel door parts, the weight class of these parts is very important. Weight class means how heavy or light the parts are. At kuntai, we know that the weight of each part can change the way we ship them and how much it costs. If a part is heavy, it will cost more money to move it from one place to another. This is because heavier items need bigger trucks, more fuel, and sometimes special equipment to load and unload them safely. On the other hand, lighter parts are easier and cheaper to ship because they take up less space and need less effort to handle. Shipping costs can add up quickly if the parts are very heavy, so understanding the weight class helps kuntai plan the best way to send the parts to customers. We want to make sure you get your garage door parts on time without paying too much for shipping. Also, when the parts are sorted by weight, it helps us pack them better. For example, we can put lighter parts on top and heavier parts at the bottom inside the boxes. This way, the parts don’t get damaged during the trip. It also helps us use space inside the truck more wisely. If the parts are not sorted by weight, the truck may have empty spaces, which means we are not using the space well, and shipping becomes less cost-efficient. So, weight class is a big part of how kuntai manages shipping. By knowing the weight class of garage panel door parts, we save money and time, and we pass those savings on to you. This makes buying from kuntai a smart choice if you want good quality parts that arrive safely and without extra shipping costs.

What Are the Benefits of Buying Garage Panel Door Parts by Specific Weight Classes

Buying garage panel door parts by weight class has many good reasons. At kuntai, we organize parts by their weight so that customers can choose exactly what they need without confusion. One big benefit is that you can find the right part faster. When parts are grouped by weight, you don’t have to guess if a part will be too heavy or too light for your garage door. This saves you time and helps you avoid mistakes. Another benefit is that parts in the same weight class often match better with each other. For example, if you buy a heavy panel, you will want other heavy parts like hinges or rollers that are strong enough to hold it. If you mix heavy parts with light parts, the door might not work well or could break faster. Kuntai makes sure that parts sold together by weight class fit well and last longer. Buying by weight class can also save you money. When you get parts that work well together, you don’t have to fix problems or buy replacements too soon. This means fewer extra costs in the future. Also, shipping is cheaper when parts are grouped by weight because the order can be packed more efficiently, like we explained earlier. Another good point is safety. If you buy parts that are too heavy for your door’s system, it can be dangerous. The door might fall or not open properly. By choosing parts by weight class, kuntai helps you avoid these risks and keeps your garage safe. So, buying garage panel door parts by specific weight classes from kuntai is smart because it helps you get the right parts faster, saves money, and keeps your garage door working safely for a long time.

How Weight Class Influences Garage Panel Door Parts Compatibility and Installation

The weight class garage door panel hinges of garage panel door parts is very important when it comes to making sure parts fit together well and are easy to install. At kuntai, we pay close attention to this because a garage door is made up of many parts that must work as a team. If the parts are not matched by weight, the door might not open or close smoothly. For example, a heavy garage door panel needs strong springs and sturdy rollers to hold it up. If you use light parts with a heavy panel, those parts might break or wear out quickly. This means you will have to fix or replace parts often, which can be frustrating and expensive. On the other hand, if you use parts that are too heavy for a light door panel, the door might be harder to open and garage panel door hinges could strain the door opener or the person opening it. Kuntai makes sure parts are grouped and sold by weight class to help customers avoid these problems. When parts are compatible in weight, installation is also easier. Installers don’t have to guess if a spring will hold the door or if a hinge can support the panel’s weight. This saves time and effort. Also, the door will work better and last longer because all parts share the load properly. Another way weight class affects installation is by safety. Heavy parts that are not installed correctly can cause accidents. By matching parts by weight, kuntai helps installers follow the right steps to keep everyone safe. Lastly, using the correct weight class helps with panel lift garage door hinges balancing the door. A well-balanced door opens and closes smoothly, which protects the parts from damage. This means fewer repairs and a longer-lasting garage door. In summary, weight class is a key factor in making sure garage panel door parts fit well, are safe to install, and help your door work perfectly. Kuntai’s focus on weight classes means you get parts that match and make your garage door the best it can be.

Commercial garage door braces are important parts that help keep big doors strong and safe. These braces stop the door from bending or shaking when it opens and closes. In factories or stores, garage doors are used a lot, so the braces must be tough. At kuntai, we know how important it is to pick the right materials for these braces. The materials need to hold up against wind, heavy use, and sometimes even bad weather. Not all materials work the same, so it’s smart to know what each one can do. This helps make sure the garage door lasts a long time and keeps working well without breaking.

How to Choose the Best Commercial Garage Door Brace Materials for Durability

Picking the right material for garage door braces is not always easy. Durability means the brace will stay strong for a long time, even when it faces heavy use or weather problems. For example, some metals like steel are very strong and do not break easily. But steel can rust if it is not coated or treated right. If you choose steel, it should have a special cover to stop rust. On the other hand, aluminum does not rust, but it is softer and can bend more easily. So, aluminum braces might not hold as much weight but last longer outside without much care. Another material is wood, but it is not very common for commercial braces because it can get weak from water or bugs. Sometimes, braces are made with a mix of materials to get the best of both worlds, like steel covered with a rust-proof layer. At kuntai, we look at all these things when making our braces. We want them to last many years and keep your garage door working smoothly. Also, the weight of the material matters. Heavier materials can give more strength but make the door harder to open. Lighter materials are easier to move but might not be as strong. So, choosing is about balance. Think about where the door is, how often it opens, and what kind of weather it faces. That way, the brace will hold up and keep the door safe every day.

What Are the Most Popular Materials for Commercial Garage Door Braces in Bulk

When buying garage door braces in large amounts, many people want materials that are easy to get and cost less but still work well. Steel is often the favorite. It is strong, easy to find, and can be made in many shapes and sizes. Because steel is popular, companies like kuntai can produce it quickly and keep the price good for customers. Zinc-coated steel is a special type that resists rust better, so it is used a lot when the braces will be outside. Aluminum is also popular for places where rust is a big problem, like near the sea or in very wet areas. Though aluminum costs more, it can save money by not needing repairs or paint. Plastic or composite materials are not common in commercial braces because they are not strong enough for heavy doors. But in some special cases, they might be used where weight is more important than strength. When buying in bulk, it is smart to think about how easy it is to work with the material. Steel can be cut, welded, and shaped in many ways, which helps make many custom brace designs. Kuntai’s experience shows that choosing the right material in large amounts helps save money and time. It also means the garage doors will be safer and last longer. If you plan to buy many braces, it’s good to talk to experts who know the materials well. They can help pick what works best for your needs and budget. That is how kuntai helps customers: providing strong, smart choices for every job.

What Makes Steel the Top Material for Commercial Garage Door Braces?

When it comes to commercial garage door braces, steel is by far the best material to use. This is because steel is very strong and can handle a lot of weight and pressure. Commercial garage doors are usually large and heavy, so the braces that support them need to be tough. Steel provides the strength needed to keep the door secure and working properly for a long time. Another reason steel is popular is because it does not easily bend or break. This means that even if strong winds, heavy rain, or other weather problems happen, steel braces will still hold the door in place. They help protect the garage and everything inside it. Also, steel can last a long time without needing to be replaced. This makes it a good choice for businesses that want to save money in the long run. At kuntai, we use high-quality steel in all our commercial garage door braces to make sure they are strong and durable. Steel can also be treated to resist rust and corrosion, which is important because garage doors are often outside and exposed to rain and moisture. Without this protection, metal parts could become weak and unsafe. Steel braces from kuntai are made with special coatings that keep them safe from rust for many years. All of these reasons make steel the top material for commercial garage door braces. It is strong, long-lasting, and able to protect your commercial space well. When you choose garage door braces made from steel by kuntai, you are getting a product that can handle tough conditions and keep your doors safe and working smoothly.

What Common Material Issues Should Wholesale Buyers Avoid in Garage Door Braces?

When buying garage door braces in bulk, wholesale buyers need to be very careful about the materials used. Many problems can happen if the wrong materials are chosen. One common issue is using low-quality metal that is not strong enough. Some braces might look good at first, but if the metal is thin or weak, the braces can bend or break easily. This puts the whole garage door at risk of falling or getting damaged. Another problem is poor rust resistance. If the metal is not properly treated or coated, it can rust quickly. Rust weakens the metal and makes it unsafe. Wholesale buyers should avoid braces made from metals that do not have strong protection against rust. At kuntai, we make sure every brace is coated with the best rust-resistant materials so they last longer and stay safe. Some braces are also made with metal that has many impurities or poor manufacturing quality. This can cause the metal to crack or fail under pressure. Wholesale buyers should check for signs of poor metal quality, like uneven surfaces or rough edges. These signs may mean the metal is not good enough for commercial use. Another issue is choosing materials that are too heavy or too light. Very heavy braces can be hard to install and may put extra stress on the garage door system. On the other hand, braces that are too light might not provide enough support. Finding the right balance is important. Wholesale buyers should work with trusted companies like kuntai that test their materials carefully to provide braces that are just the right weight and strength. Lastly, some braces may have poor welding or joining methods. Even if the metal is strong, weak welds can cause the brace to break. Wholesale buyers should ask about the welding quality and make sure the braces are made with strong, reliable connections. Avoiding these common material issues helps buyers get braces that keep commercial garage doors safe and working well. By choosing braces made from high-quality steel with good rust protection and strong welds, like those from kuntai, wholesale buyers can avoid many problems and protect their investment.

How to Identify Superior Material Quality in Wholesale Commercial Garage Door Braces

Knowing how to spot high-quality materials in wholesale commercial garage door braces is very important. Buyers want to make sure they get braces that will last and do a good job. One way to identify superior material quality is by checking the type of metal used. The best braces are made from strong steel that is thick enough to handle heavy loads. If the metal feels too thin or light, it might not be good quality. At kuntai, we use only thick, strong steel for our braces to ensure they can support big commercial doors. Another way is to look at the surface of the braces. High-quality garage door brace braces have smooth, even surfaces without dents, scratches, or rough spots. These imperfections could mean the metal is weak or not properly processed. Good quality braces also have a clean and even coating that protects against rust. You can often see this as a shiny or matte finish that covers the entire brace. The coating should be smooth and not peeling or flaking. Kuntai’s braces are coated carefully to keep rust away for many years. A third way to check quality is to ask about the manufacturing process. Superior braces are made using modern machines and strict quality controls. This helps make sure each brace is the same size, shape, and strength. You can ask the supplier for garage door panel brace certificates or test results that show the metal’s strength and durability. Kuntai provides these documents to prove the quality of our garage door braces. Also, look closely at the welding or joints where parts are connected. Good quality braces have clean, strong welds without cracks or gaps. Poor welds can cause the brace to break under pressure. Kuntai uses advanced welding techniques to make sure every brace is strong and safe. Finally, buyers can sometimes test the braces themselves. Simple tests like bending or tapping the metal can show if it feels solid Hinges & Brackets or weak. High-quality steel sounds firm and does not bend easily. By using these tips, wholesale buyers can identify superior material quality in commercial garage door braces. Choosing braces made from strong steel, with smooth surfaces, good coatings, and strong welds, like those from kuntai, helps ensure the garage doors will be safe, durable, and reliable for many years.

When it comes to finding the best wear-resistant bearings for your industrial needs, look no further than CIXIHOTO. Our robust bearing solutions offer superior wear resistance, ensuring that your machinery operates smoothly and efficiently. With a focus on quality and durability, our bearings are designed to withstand the toughest conditions, increasing the lifespan of your equipment and reducing the need for frequent replacements.

How to find the best wear-resistant bearings for your industrial needs

Finding the best wear-resistant bearings for your industrial needs can be a daunting task, but with CIXIHOTO, the process is made simple. When selecting bearings for your machinery, it is essential to consider factors such as load capacity, speed ratings, temperature resistance, and lubrication requirements. CIXIHOTO offers a wide range of bearings that are specifically designed to meet the demands of various industries, ensuring optimal performance and longevity.

Our team of experts at CIXIHOTO can help you identify the right bearing solutions for your specific applications. With decades of experience in the industry, we understand the unique challenges that come with industrial manufacturing. By taking the time to assess your needs and requirements, we can recommend bearings that will enhance productivity and efficiency in your operations.

In addition to providing high-quality bearings, CIXIHOTO offers comprehensive support services to ensure that your equipment runs smoothly. From installation assistance to maintenance and repair, our team is dedicated to helping you get the most out of your bearing solutions. With CIXIHOTO, you can trust that your machinery is in good hands, allowing you to focus on growing your business and meeting your production goals.

Boost productivity with our superior wear-resistant bearings

One of the key benefits of using CIXIHOTO's superior wear-resistant bearings is the significant boost in productivity that they provide. By investing in high-quality bearings that offer superior wear resistance, you can reduce downtime and maintenance costs, leading to increased overall efficiency in your operations. With CIXIHOTO's bearings, you can rest assured that your equipment will perform at its best, even in the most demanding environments.

In addition to boosting productivity, our wear-resistant bearings also contribute to a safer work environment. By minimizing the risk of equipment failure and breakdowns, you can create a more reliable and secure workplace for your employees. This not only improves overall productivity but also enhances employee morale and satisfaction.

Furthermore, CIXIHOTO's superior wear-resistant bearings are designed to deliver consistent performance over time, ensuring that your machinery operates at peak efficiency for extended periods. With our bearings, you can maximize the lifespan of your equipment and minimize the need for costly repairs and replacements. This long-term reliability and durability make CIXIHOTO the go-to choice for businesses looking to optimize their industrial operations and achieve sustainable growth.

Wholesale options for top-of-the-line wear-resistant bearings:

At CIXIHOTO, we understand the importance of having durable and long-lasting bearings for industrial use. That's why we offer wholesale options for our top-of-the-line wear-resistant bearings. Our bearings are designed to withstand heavy loads, high temperatures, and harsh environments, making bearing sleeve them the perfect choice for a wide range of applications. Whether you need bearings for mining equipment, agricultural machinery, or manufacturing processes, our wholesale options provide cost-effective solutions without compromising on quality.

Common issues with traditional bearings solved with our robust solutions:

Traditional bearings often face issues such as corrosion, wear, and premature failure, leading to costly downtime and maintenance. At CIXIHOTO, we have developed robust solutions to address these common issues and provide our customers with bearings that offer superior wear resistance and longevity. Our bearing sleeve types bearings are made from high-quality materials and undergo rigorous testing to ensure they meet the highest standards of durability and performance. With our robust solutions, you can trust that your equipment will run smoothly and efficiently, reducing the need for frequent replacements and repairs.

Where to buy durable bearings in bulk for industrial use:

If you are looking to buy durable bearings in bulk for industrial use, look no further than CIXIHOTO. We offer a wide range of high-quality bearings that are designed to meet the demanding requirements of various industries. Whether adapter bearing sleeve you need bearings for heavy machinery, conveyor systems, or automotive applications, we have you covered. Our bearings are available in bulk quantities at competitive prices, making it easy for you to stock up on the supplies you need for your operations. With CIXIHOTO, you can trust that you are getting reliable and long-lasting bearings that will keep your equipment running smoothly for years to come.