@pink143

- Followers 0

- Following 0

- Updates 472

Blog

CombineTech is proud to introduce cutting-edge battery technology solutions for industrial machinery. Our innovative batteries are designed to enhance the performance and efficiency of a wide range of industrial applications. From powering heavy equipment to providing reliable energy storage solutions, our batteries are at the forefront of modern industrial technology.

Cutting-Edge Battery Technology Solutions for Industrial Machinery

CombineTech's cutting-edge battery technology solutions offer a variety of benefits for industrial machinery. Our batteries are designed to provide long-lasting power, ensuring uninterrupted operation of equipment in demanding industrial environments. With advanced energy storage capabilities, our batteries can optimize the performance of machinery, leading to increased productivity and reduced downtime.

Moreover, our cutting-edge batteries are equipped with smart features such as remote monitoring and predictive maintenance, allowing for proactive management of battery health and performance. This helps in preventing unexpected breakdowns and minimizing repair costs, ultimately improving overall operational efficiency. Additionally, our batteries are lightweight and compact, making them easy to install and integrate into existing industrial systems.

Furthermore, CombineTech's battery technology solutions are environmentally friendly, with a focus on sustainability and energy efficiency. By using our batteries, industrial companies can reduce their carbon footprint and contribute to a cleaner, greener future. Our commitment to innovation and quality ensures that our batteries meet the highest industry standards, providing reliable power solutions for a wide range of industrial applications.

Wholesale Battery Tech for Industrial Applications

In addition to offering cutting-edge battery technology solutions for industrial machinery, CombineTech also provides wholesale options for businesses looking to incorporate our batteries into their operations. Our wholesale battery tech packages are designed to meet the unique needs of industrial applications, offering cost-effective solutions for companies looking to upgrade their energy storage systems.

Whether you are a small manufacturing facility or a large industrial operation, CombineTech's wholesale battery tech options can help you improve the performance and efficiency of your machinery. Our expert team can work closely with you to assess your specific requirements and recommend the best battery solutions for your needs. With our extensive experience in industrial manufacturing, we understand the importance of reliable power sources in driving business success.

By partnering with CombineTech for wholesale battery tech, businesses can benefit from our expertise in supply chain logistics, OEM procurement, and strategic sourcing. Our commitment to quality and innovation ensures that you receive top-of-the-line battery technology solutions that are tailored to your unique industrial applications. Trust CombineTech to power your industrial machinery with cutting-edge battery technology that delivers exceptional performance and value.

When it comes to powering industrial machinery, having top-quality battery technology is essential. CombineTech offers cutting-edge battery solutions designed specifically for use in industrial settings. These advanced batteries are reliable, long-lasting, and efficient, making them the perfect choice for powering heavy-duty machinery in factories, warehouses, and other industrial environments.

Where to Find Top-Quality Battery Tech for Machinery

Finding top-quality battery technology for industrial machinery can be challenging, but CombineTech makes it easy. Our batteries are known for their high performance and reliability, making them the ideal choice for powering a wide range of industrial equipment. Whether you need batteries for forklifts, cranes, or other machinery, CombineTech has you covered. Our batteries are designed to withstand the rigors of industrial use, providing consistent power when you need it most. With CombineTech, you can be confident that your machinery will always be powered up solar battery storage and ready to go.

Affordable Wholesale Battery Solutions for Machinery

CombineTech offers affordable wholesale battery solutions for industrial machinery, making it easy to keep your equipment powered up without breaking the bank. Our wholesale prices make it cost-effective to outfit all of your machinery with high-quality batteries, ensuring that your operations run smoothly and efficiently. With CombineTech solar energy battery storage , you can get the power you need at a price that fits your budget, allowing you to focus on what matters most – keeping your business running smoothly.

Best Battery Tech for Industrial Machinery

When it comes to the best battery technology for industrial machinery, CombineTech stands out from the competition. Our batteries are designed to deliver optimal performance, long life, and reliable power, making them the perfect choice solar power and battery storage for powering even the most demanding machinery. With CombineTech batteries, you can trust that your equipment will always have the power it needs to get the job done. Don't settle for subpar battery technology – choose CombineTech for the best in cutting-edge battery solutions for industrial machinery.

Enhance Retail Efficiency with Sunlanrfid RFID Garment Labels

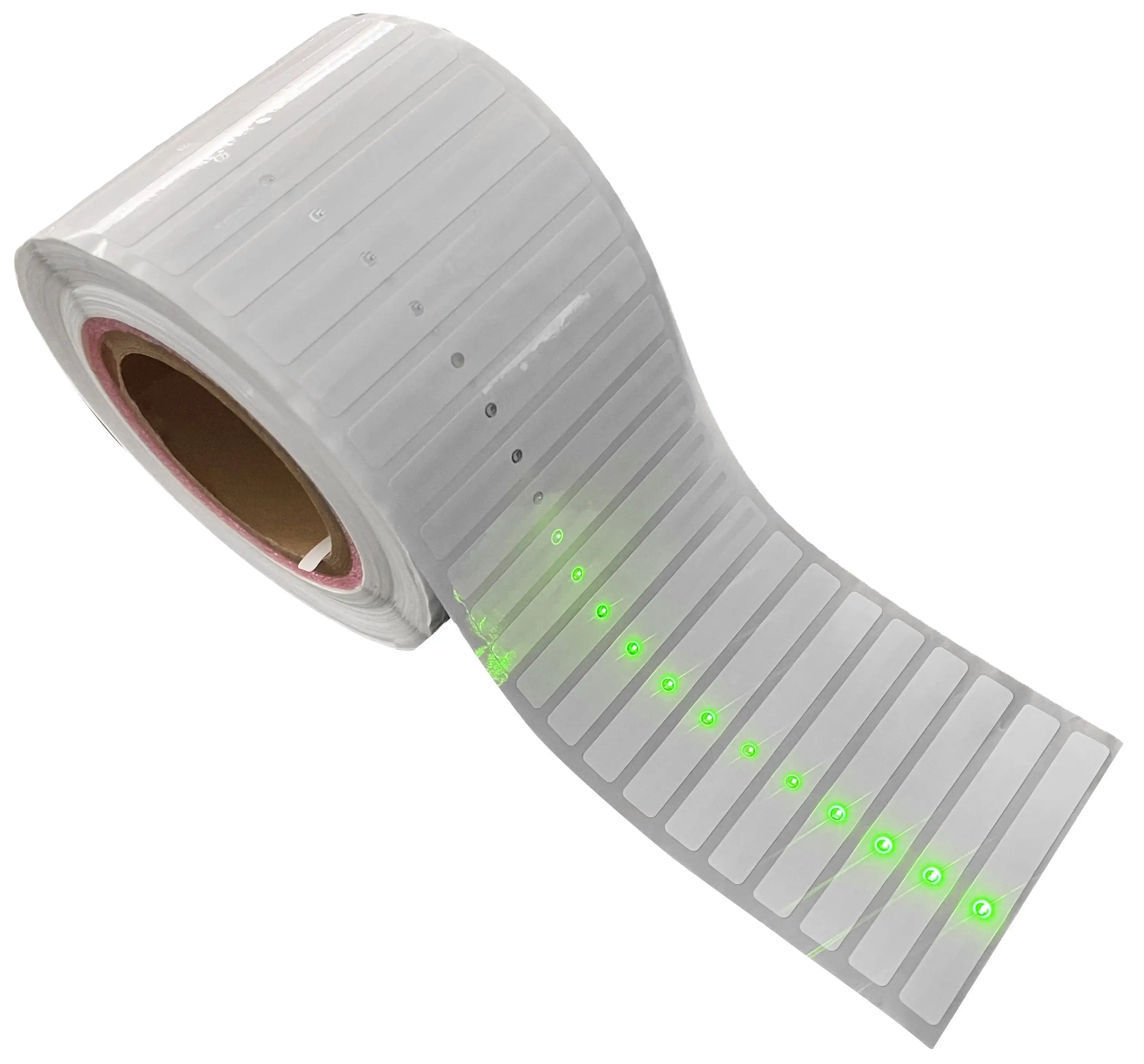

Sunlanrfid's RFID garment labels are revolutionizing retail inventory management by providing a smart and efficient way to track and monitor products. These labels use radio frequency identification technology to store and transmit data, allowing retailers to easily keep track of their inventory in real-time. By utilizing Sunlanrfid's RFID garment labels, retailers can streamline their operations, reduce errors, and improve overall efficiency in managing their inventory.

Unlock Inventory Optimization Secrets with Sunlanrfid Technology

Sunlanrfid's cutting-edge RFID technology unlocks the secrets to optimal inventory management in the retail industry. By implementing Sunlanrfid's RFID garment labels, retailers can gain valuable insights into their inventory levels, track product movements, and identify trends to make informed decisions. This technology enables retailers to optimize their inventory levels, reduce stockouts, minimize overstock situations, and ultimately improve their bottom line. With Sunlanrfid's RFID technology, retailers can unlock the full potential of their inventory management system and stay ahead of the competition.

Revolutionize Retail Management with Sunlanrfid RFID Solutions

SUNLANRFID's RFID garment labels are changing the game for retail management. These small, powerful labels are equipped with radio frequency identification technology that allows retailers to track their inventory with ease. By simply scanning the labels, retailers can access real-time information about their stock levels, location of items, and even monitor trends in customer purchases. This technology streamlines the inventory management process, reducing the risk of human error and ensuring that items are always in stock when customers need them.

Stay Ahead of the Competition with Sunlanrfid Inventory Management

In today's rfid clothes tag competitive retail landscape, staying ahead of the competition is crucial. SUNLANRFID's RFID solutions give retailers the edge they need to succeed. By optimizing inventory management with RFID garment labels, retailers can improve efficiency, reduce costs, and enhance the overall shopping experience for customers. With real-time data at their fingertips, retailers can make informed decisions about restocking, pricing, and marketing rfid for clothes strategies. This level of insight allows retailers to anticipate customer demands and adapt quickly to changing market conditions, giving them a significant advantage over competitors.

Discover the Power of Sunlanrfid for Wholesale Inventory Management

For wholesalers, managing inventory can be a complex and time-consuming process. SUNLANRFID's RFID solutions simplify wholesale inventory management by providing accurate, up-to-date information about stock levels and item locations. With RFID garment labels, wholesalers can track their inventory in real-time, streamline order fulfillment, and reduce the risk rfid laundry tag of stockouts. This level of visibility and control allows wholesalers to optimize their operations, improve customer satisfaction, and ultimately increase profitability. By harnessing the power of SUNLANRFID's RFID technology, wholesalers can take their inventory management to the next level and achieve greater success in the competitive wholesale market.

Tenfront is your go-to source for all your auto parts needs, providing a wide range of products to keep your vehicles running smoothly. With a focus on quality and customer satisfaction, Tenfront ensures that you get the best parts at competitive prices. Whether you are a small repair shop or a large dealership, Tenfront is the trusted supplier you can rely on.

How to Save Big on Wholesale Auto Parts

When it comes to saving money on wholesale auto parts, Tenfront has you covered. By purchasing in bulk, you can take advantage of discounted prices and special deals that will help you maximize your savings. Whether you need engine parts, brakes, or filters, buying wholesale from Tenfront can help you cut costs and increase your profit margins.

Not only does buying wholesale from Tenfront save you money, but it also ensures that you have a reliable supply of high-quality parts on hand whenever you need them. This can help you avoid costly delays and keep your customers happy. With Tenfront as your wholesale auto parts supplier, you can rest assured that you are getting the best value for your money.

Discover the Latest Trends in Auto Parts

As the auto industry continues to evolve, so do the trends in auto parts. At Tenfront, we stay up-to-date with the latest advancements in technology and materials to provide our customers with the most innovative products on the market. From eco-friendly options to smart technologies, we offer a wide range of cutting-edge auto parts to meet the changing needs of our customers.

One of the latest trends in auto parts is the shift towards electric vehicles. As more and more people switch to electric cars, the demand for electric vehicle parts is on the rise. At Tenfront, we have a selection of electric vehicle parts to help you stay ahead of the curve and cater to this growing market.

In addition to electric vehicle parts, Tenfront also offers a variety of other trending auto parts, such as advanced safety features, connectivity solutions, and Engine System performance enhancements. By staying informed about the latest trends in auto parts, we can ensure that our customers have access to the most up-to-date products to keep their vehicles running smoothly.

Unlock Exclusive Wholesale Deals on Auto Parts

At tenfront, we pride ourselves on offering exclusive wholesale deals on a wide range of auto parts. Whether you are a mechanic, car enthusiast, or own an auto repair shop, we have everything you need to keep vehicles running smoothly. By purchasing in bulk from us, you can save money and ensure that you always have the parts Solenoid Valve you need on hand. Our user-friendly website makes it easy to browse our extensive inventory and place orders quickly. With our competitive prices and top-notch customer service, tenfront is the ultimate destination for all your auto parts needs.

Why Tenfront is the Go-To Choice for Auto Parts Buyers

There are many reasons why tenfront is the go-to choice for auto parts buyers. Not only do we offer exclusive wholesale deals, but we also provide high-quality products from trusted brands. Our team of experts is dedicated to helping you find the right parts for your specific needs and budget. We understand the importance of having reliable auto parts, which is why we carefully select each product in our inventory. Additionally, our fast shipping and excellent customer support ensure that you have a seamless shopping experience with us. When you choose tenfront, you can trust that you are getting the best value for your money.

Common Questions About Wholesale Auto Parts Answered

If you are new to purchasing auto parts wholesale, you may have some common questions. One Cylinder Head Gasket of the most frequently asked questions is about the quality of wholesale auto parts. At tenfront, we guarantee that all of our products meet high standards of quality and reliability. Another common question is about the ordering process for wholesale auto parts. Our website makes it easy to search for specific parts, add them to your cart, and complete your purchase securely. If you have any questions or concerns along the way, our customer service team is here to help. By choosing tenfront for your wholesale auto parts needs, you can have peace of mind knowing that you are getting top-notch products at unbeatable prices.

Rice Bran: Unlocking Hidden Nutrition from Everyday Rice

Rice bran is a powerhouse of nutrients that often goes unnoticed in our daily meals. Zhunong Mizhen is dedicated to bringing awareness to the health benefits of rice bran and how it can improve your overall well-being. By incorporating rice bran into your diet, you can unlock a wealth of essential nutrients that support a healthy lifestyle.

Discover the Health Benefits of Rice Bran

Rice bran is the outer layer of the rice grain that is removed during the milling process. While it may seem like a byproduct, rice bran is actually a treasure trove of nutrients that can benefit your health in numerous ways. One of the key components of rice bran is fiber, which is essential for digestive health and can help regulate blood sugar levels. Additionally, rice bran is rich in antioxidants, such as vitamin E and gamma-oryzanol, which can help protect your cells from damage caused by free radicals. These antioxidants play a crucial role in reducing inflammation and lowering the risk of chronic diseases.

Moreover, rice bran contains essential micronutrients like iron, zinc, and magnesium, which are vital for maintaining a healthy immune system and supporting overall well-being. These nutrients play a crucial role in various bodily functions, from energy production to immune response. By incorporating rice bran into your diet, you can ensure that your body is getting the necessary nutrients it needs to function optimally. Additionally, rice bran is a good source of plant-based protein, making it an excellent option for individuals looking to increase their protein intake without relying on animal products. Whether you sprinkle it over your morning oatmeal or mix it into your favorite baked goods, rice bran is a versatile ingredient that can easily be incorporated into your daily meals.

How Rice Bran Can Improve Your Health

Incorporating rice bran into your diet can have a significant impact on your overall health and well-being. One of the key benefits of rice bran is its ability to support heart health. The antioxidants found in rice bran can help lower cholesterol levels and reduce the risk of heart disease. Additionally, the fiber in rice bran can help lower blood pressure and improve overall cardiovascular health. By adding rice bran to your diet, you can take proactive steps to protect your heart and reduce the risk of heart-related issues.

Furthermore, rice bran can also contribute to weight management and digestive health. The fiber in rice bran helps promote feelings of fullness, which can prevent overeating and support weight loss efforts. Additionally, the fiber acts as a prebiotic, feeding the beneficial bacteria in your gut and promoting a healthy digestive system. By including rice bran in your meals, you can support a healthy weight and improve your overall digestive health. Overall, rice bran is a nutrient-dense ingredient that can enhance the nutritional value of your meals and support your health in numerous ways. By incorporating rice bran into your diet, you can unlock hidden nutrition from everyday rice and reap the benefits of this powerful ingredient.

Incorporating Rice Bran into Your Everyday Meals

Zhunong Mizhen rice bran is a nutritious ingredient that can easily be added to your daily meals. You can sprinkle it on top of salads, mix it into yogurt or smoothies, or even use it as a coating for baked chicken or fish. Rice bran is a great source of fiber, antioxidants, and essential vitamins and minerals. By incorporating Zhunong Mizhen rice bran into your everyday meals, you can boost the nutritional value of your diet and support your overall health and well-being.

Why Rice Bran is the Latest Health Trend

Rice bran has been gaining popularity as a health trend because of its numerous health benefits. It is a rich source of antioxidants, which can help protect your cells from damage caused by free radicals. Rice bran is also high in fiber, which can help support healthy digestion and keep you Rice Bran feeling full and satisfied. Additionally, rice bran is a good source of essential vitamins and minerals, such as vitamin E, magnesium, and zinc. With all of these health benefits, it's no wonder that rice bran is the latest health trend that everyone is talking about.

The Rising Popularity of Rice Bran in Wholesale Markets

In recent years, the demand for rice bran has Feed Grade Rice Bran been steadily increasing in wholesale markets. This is due to the growing awareness of its health benefits and nutritional value. Many food manufacturers and retailers are now incorporating rice bran into their products, such as bread, cereal, and snack bars. Additionally, more people are seeking out rice bran as a standalone ingredient to use in their own cooking and baking. As the popularity of rice bran continues to rise, it is becoming easier Food Grade Rice Bran to find and purchase this nutritious ingredient in bulk quantities at wholesale markets. Whether you are a food manufacturer looking to create healthier products or a consumer looking to improve your diet, rice bran from Zhunong Mizhen is a versatile and nutritious ingredient that can help you unlock hidden nutrition from everyday rice.

YHWY provides highly professional engineering support for XCMG machinery, ensuring that our customers receive top-notch service and assistance for their equipment. Our team of skilled engineers is dedicated to offering the best solutions for maintenance, troubleshooting, and upgrades to keep XCMG machinery running smoothly and efficiently.

Professional engineering support for XCMG machinery:

Our team of expert engineers at YHWY is well-versed in the intricacies of XCMG machinery, allowing them to provide specialized support and assistance for all types of equipment. Whether it's troubleshooting a complex issue, conducting routine maintenance, or implementing upgrades, our engineers have the knowledge and experience to handle any situation with precision and efficiency. By relying on our professional engineering support, XCMG machinery owners can rest assured that their equipment is in good hands and will perform at its best.

High quality service for XCMG machinery:

In addition to our professional engineering support, YHWY is committed to delivering high-quality service to our customers with XCMG machinery. Our dedication to excellence means that we go above and beyond to ensure that every aspect of our service meets the highest standards. From prompt response times to thorough inspections and detailed reports, our service for XCMG machinery is designed to exceed expectations and provide our customers with peace of mind. By choosing YHWY for engineering support and service, XCMG machinery owners can trust that their equipment is in the best possible hands for optimal performance and longevity.

Top-notch engineering support for XCMG machinery

When it comes to ensuring the optimal performance and longevity of XCMG machinery, having access to highly professional engineering support is essential. At YHWY, we understand the importance of providing top-notch engineering support to our customers who rely on XCMG machinery for their business operations. Our team of skilled engineers is well-versed in the intricate workings of XCMG machinery and can provide expert guidance and assistance to address any issues that may arise.

From routine maintenance and troubleshooting to more complex repairs and upgrades, our engineering support services are designed to keep XCMG Products machinery running smoothly and efficiently. By entrusting your machinery to our team at YHWY, you can rest assured that you are receiving the highest level of expertise and care to keep your operations running smoothly.

Wholesale engineering support for XCMG machinery

At YHWY, we offer wholesale engineering support for XCMG machinery to cater to the needs of businesses with multiple units of XCMG machinery. Our wholesale engineering support packages are designed to provide cost-effective solutions for businesses looking to maintain and optimize their fleet of XCMG Crane Parts machinery without breaking the bank.

Whether you have a small fleet or a large number of XCMG machinery units, our team at YHWY can customize a wholesale engineering support package to meet your specific needs. With our expertise and dedication to excellence, you can trust that your XCMG machinery will receive the highest level of care and attention to keep your operations running smoothly and efficiently.

Where to find reliable engineering support for XCMG machinery

If you are in need of reliable engineering support for your XCMG machinery, look no further than YHWY. Our team of skilled engineers is dedicated to providing the highest level of expertise and care to keep your XCMG Grader Parts machinery running smoothly and efficiently. With our commitment to excellence and customer satisfaction, you can trust that your machinery is in good hands with YHWY.

Whether you are in need of routine maintenance, troubleshooting, repairs, or upgrades for your XCMG machinery, our team at YHWY is here to help. Contact us today to learn more about our engineering support services and how we can help you optimize the performance and longevity of your XCMG machinery.

XURON's Independent DTF R&D Capability is paving the way for innovative solutions in the manufacturing industry. With a focus on Wholesale Buyers, XURON is redefining the landscape of manufacturing with its cutting-edge research and development capabilities. By taking an independent approach to DTF R&D, XURON is setting itself apart as a leader in the field, offering unique and tailored solutions to meet the specific needs of wholesale buyers.

Innovative DTF R&D Capabilities for Wholesale Buyers

XURON's innovative DTF R&D capabilities are designed to cater to the needs of wholesale buyers across various industries. By leveraging advanced technologies and strategic partnerships, XURON is able to develop customized solutions that optimize production processes and enhance overall efficiency. From supply chain logistics to digital transformation, XURON's DTF R&D team is constantly pushing the boundaries of what is possible in the manufacturing world. By staying ahead of industry trends and anticipating future demands, XURON is able to offer wholesale buyers a competitive edge in today's fast-paced market.

XURON's Independent Approach

XURON's independent approach to DTF R&D is a key factor in its success. By avoiding reliance on external partners and instead focusing on in-house expertise, XURON is able to maintain full control over the research and development process. This allows for greater flexibility and agility in responding to changing market demands, ensuring that XURON remains at the forefront of innovation. Additionally, XURON's independent approach enables the company to protect its intellectual property and maintain a strong competitive advantage in the industry. By combining a commitment to independence with a dedication to excellence, XURON is setting a new standard for manufacturing companies looking to drive sustainable growth and success.

Exploring the Benefits of XURON's Independent R&D

XURON, a leading company in the manufacturing industry, is proud to offer independent DTF (Design, Test, and Fabrication) R&D capabilities. This means that our team of experts can create innovative solutions and products from start to finish without relying on external resources. By investing in our own research and development, we can stay ahead of the curve and bring cutting-edge technology to our customers.

One of the key benefits of XURON's independent R&D capabilities is the ability to customize products to meet specific needs. Our team can work closely with clients to understand their requirements and develop tailored solutions that address their unique challenges. This flexibility allows us to create products that are truly one-of-a-kind and stand out in the market.

Additionally, having Dtf machine independent R&D capabilities means that XURON can react quickly to changes in the industry and market demands. We are not limited by external factors or dependencies, allowing us to stay agile and responsive to evolving trends. This agility is crucial in today's fast-paced business environment, where being able to adapt quickly can make all the difference.

Stay Ahead of the Competition with XURON's DTF Capabilities

In the competitive manufacturing industry, staying ahead of the competition is key to success. XURON's DTF capabilities give us a significant advantage over other companies by allowing us to innovate faster and more efficiently. Our independent R&D team is constantly exploring new technologies and processes to push Direct to film printer the boundaries of what is possible in manufacturing.

By leveraging our DTF capabilities, XURON can bring products to market quicker and with higher quality. This means that our customers can benefit from the latest advancements in technology and stay ahead of their competitors. Our commitment to innovation and excellence sets us apart in the industry and ensures that we are always at the forefront of manufacturing trends.

Enhancing Your Product Line with XURON's Manufacturing Expertise

XURON's extensive manufacturing expertise is another key advantage that sets us apart from the competition. Our team has years of experience in developing and producing high-quality products for a wide range of industries. This wealth of knowledge allows us to offer valuable insights and guidance to our clients, helping them enhance their product lines and achieve their business goals.

Whether you are looking to improve an existing product or develop something entirely new, XURON's Dtf transfer printer manufacturing expertise can help you every step of the way. From concept design to final production, our team is dedicated to delivering exceptional results that exceed expectations. With XURON by your side, you can trust that your product line will be in good hands and reach its full potential.

High-Performance Special Labor Protective Clothing is essential for keeping workers safe in various industries. This type of clothing is designed to provide protection against different workplace hazards, such as chemicals, flames, and sharp objects. Safety Technology offers a wide range of high-performance special labor protective clothing for wholesale buyers, ensuring that workers have the necessary protection to carry out their duties safely and efficiently.

High-Performance Special Labor Protective Clothing for Wholesale Buyers

Safety Technology understands the importance of providing high-quality protective clothing to wholesale buyers. Our range includes items such as flame-resistant coveralls, chemical-resistant suits, and cut-resistant gloves. These products are designed to meet the specific needs of different industries, ensuring that workers are protected in various work environments. For example, our flame-resistant coveralls are made from durable materials that can withstand high temperatures, making them ideal for workers in industries such as welding and metal fabrication. Additionally, our chemical-resistant suits provide a barrier against hazardous substances, keeping workers safe when handling chemicals or working in contaminated areas.

How to Choose the Best Labor Protective Clothing for Your Needs

When choosing labor protective clothing, it is essential to consider the specific hazards present in your workplace. For example, if you work in an environment where there is a risk of exposure to flames, it is crucial to select flame-resistant clothing that meets industry standards. Similarly, if you work with sharp objects, cut-resistant gloves can help prevent injuries. Safety Technology offers a range of options to suit different needs, ensuring that workers have the right level of protection. It is also important to consider factors such as comfort and fit when choosing protective clothing, as workers need to be able to move freely and comfortably while wearing their gear. By selecting the right protective clothing for your needs, you can ensure that workers stay safe and productive on the job.

Common Issues with Labor Protective Clothing and How to Address Them

When it comes to labor protective clothing, there are a few common issues that workers often face. One of the main issues is that the clothing may not provide enough protection against hazardous materials or environments. This can lead to injuries or health problems for workers. To address this issue, Safety Technology has developed high-performance labor protective clothing that is designed to provide maximum protection against a wide range of hazards. Our clothing is made from durable materials that can withstand the toughest conditions, ensuring that workers stay safe on the job.

Another common issue with labor protective clothing is that it may not be comfortable to wear for long periods of time. This can make it difficult for workers to focus on their tasks and can lead to decreased productivity. To address this issue, Safety Technology has designed our high-performance clothing to be lightweight and breathable, ensuring that workers stay comfortable and can move freely while wearing our clothing. By addressing these common issues, Safety Technology is able to provide workers with the protection they need without sacrificing comfort or mobility.

Why Our High-Performance Labor Protective Clothing is a Must-Have

Safety Technology's high-performance labor protective clothing is a must-have for any worker who wants to stay safe on the job. Our clothing is designed to provide maximum protection against a wide range of hazards, including chemicals, flames, and sharp objects. With our clothing, workers can feel confident knowing that they are protected no matter what challenges they may face on the job.

In addition to providing fire retardant clothing superior protection, Safety Technology's high-performance clothing is also incredibly durable and long-lasting. Our clothing is made from high-quality materials that can withstand the toughest conditions, ensuring that workers can rely on their protective gear day in and day out. By investing in our high-performance clothing, workers can save money in the long run by avoiding the need to constantly replace worn-out gear.

The Benefits of Investing in Quality Labor Protective Clothing

There are many benefits to investing in quality labor Flame retardant clothing protective clothing from Safety Technology. One of the main benefits is that our clothing can help prevent injuries and accidents on the job. By providing maximum protection against a wide range of hazards, our clothing can help keep workers safe and reduce the risk of workplace incidents.

In addition to safety benefits, our high-performance clothing can also help improve worker morale and productivity. When workers feel safe and comfortable in their protective gear, they are able to focus on their tasks and perform at their best. This can lead to increased efficiency and higher quality work, benefiting both workers and employers alike.

Overall, investing in quality labor protective clothing from Safety Technology is a smart Flame resistant workwear choice for any business or worker. With superior protection, comfort, and durability, our high-performance clothing is a must-have for anyone who wants to stay safe and productive on the job.

Nanjing Sundge Chemical New Material Co., Ltd: Pioneering Excellence in Chemical Innovation

By pink143, 2025-11-13

Nanjing Sundge Chemical New Material Co., Ltd is an organization that is leading focuses on the development, production, and sale of innovative chemical services and products. The business has been solutions that are supplying are top-quality meet the growing needs of the chemical industry for quite some time. With its advanced research and development practices, cutting-edge technologies, and consumer that is outstanding, Sundge Chemical has proven itself to be a preeminent leader into the field of chemical innovation

Benefits

One of the advantages of utilizing Sundge Chemical services and products is their superior quality. Their products or services are designed to be extremely cost-effective, efficient, and easy to utilize. Sundge Chemical's advanced technologies, materials, and manufacturing processes are utilized to make sure that their products or services meet the quality standards which can be highest in the industry

Innovation

Innovation is at the core of Sundge Chemical's business model. The corporation's R and D department is continually exploring ideas which can be new technologies, and processes to improve product performance and efficiency. Their solutions that are innovative helped to change the face of the chemical industry, and they continue to set standards that are brand new breakthrough technologies and applications

Safety

Sundge Chemical places a priority that is high security and sustainability that is environmental. They adhere towards the strictest safety criteria and regulations, and all sorts of of their items are tested to ensure they're clear of harmful contaminants and substances. In addition, the business is committed to reducing its effect that is environmental and tirelessly to produce eco-friendly products and manufacturing processes

Use

Sundge Chemical items are versatile and will be properly used across a range that is wide of. They are used in the manufacture of plastics, pigments, coatings, resins, and other xylitol sugar materials. Sundge Chemical has an product that is extensive which includes adhesives, sealants, coatings, and other functional materials. These products not just fulfill the needs of their customers but help to improve also performance, security, and sustainability

How to Use

Sundge Chemical items are made to be easy to use. They come with clear instructions on how to handle and apply the item safely and efficiently. The company also provides support that is xylitol sweetener technical guidance to its customers to make certain that they get the best possible results from their products. In addition, Sundge Chemical offers training and support that is on-site help customers optimize their production procedures and achieve efficiency that is maximum

Service

Sundge Chemical is dedicated to providing client service that is excellent. The business's team of experts is obviously ready to offer advice and help to customers, whether it's responding to questions that are artificial sweeteners xylitol technical assisting to solve problems, or product that is providing. Sundge Chemical also offers solutions that are tailor-made to meet the specific needs of their clients

Quality

Quality is the cornerstone of Sundge Chemical's business. The company's items are manufactured to the highest criteria, and each product is rigorously tested to ensure that it meets or exceeds industry standards. The business has established a reputation for delivering quality that is superior, and its commitment to quality is evident in all aspects of their business

Application

Sundge Chemical's items have range that is broad of across multiple industries. Their products are used on the market that is construction that is automotive, electronics industry, and several others. Whether their products are used to improve performance, reduce costs, or manufacturing that is optimize, Sundge Chemical's revolutionary solutions give you the perfect foundation for success

Conclusion

To conclude, Nanjing Sundge Chemical New Material Co., Ltd can be an ongoing business that is exemplary is leading the way in chemical innovation. The business's dedication to quality, innovation, safety, and client service sets it apart from its competitors. Sundge Chemical continues to offer the industry with cutting-edge technologies and solutions that meet the evolving needs associated with the market. By having an product that is considerable, and a customer-centered approach to company, Sundge Chemical is the industry leader in chemical innovation