@pink143

- Followers 0

- Following 0

- Updates 448

What Materials Comprise Commercial Garage Door Braces?

Commercial garage door braces are important parts that help keep big doors strong and safe. These braces stop the door from bending or shaking when it opens and closes. In factories or stores, garage doors are used a lot, so the braces must be tough. At kuntai, we know how important it is to pick the right materials for these braces. The materials need to hold up against wind, heavy use, and sometimes even bad weather. Not all materials work the same, so it’s smart to know what each one can do. This helps make sure the garage door lasts a long time and keeps working well without breaking.

How to Choose the Best Commercial Garage Door Brace Materials for Durability

Picking the right material for garage door braces is not always easy. Durability means the brace will stay strong for a long time, even when it faces heavy use or weather problems. For example, some metals like steel are very strong and do not break easily. But steel can rust if it is not coated or treated right. If you choose steel, it should have a special cover to stop rust. On the other hand, aluminum does not rust, but it is softer and can bend more easily. So, aluminum braces might not hold as much weight but last longer outside without much care. Another material is wood, but it is not very common for commercial braces because it can get weak from water or bugs. Sometimes, braces are made with a mix of materials to get the best of both worlds, like steel covered with a rust-proof layer. At kuntai, we look at all these things when making our braces. We want them to last many years and keep your garage door working smoothly. Also, the weight of the material matters. Heavier materials can give more strength but make the door harder to open. Lighter materials are easier to move but might not be as strong. So, choosing is about balance. Think about where the door is, how often it opens, and what kind of weather it faces. That way, the brace will hold up and keep the door safe every day.

What Are the Most Popular Materials for Commercial Garage Door Braces in Bulk

When buying garage door braces in large amounts, many people want materials that are easy to get and cost less but still work well. Steel is often the favorite. It is strong, easy to find, and can be made in many shapes and sizes. Because steel is popular, companies like kuntai can produce it quickly and keep the price good for customers. Zinc-coated steel is a special type that resists rust better, so it is used a lot when the braces will be outside. Aluminum is also popular for places where rust is a big problem, like near the sea or in very wet areas. Though aluminum costs more, it can save money by not needing repairs or paint. Plastic or composite materials are not common in commercial braces because they are not strong enough for heavy doors. But in some special cases, they might be used where weight is more important than strength. When buying in bulk, it is smart to think about how easy it is to work with the material. Steel can be cut, welded, and shaped in many ways, which helps make many custom brace designs. Kuntai’s experience shows that choosing the right material in large amounts helps save money and time. It also means the garage doors will be safer and last longer. If you plan to buy many braces, it’s good to talk to experts who know the materials well. They can help pick what works best for your needs and budget. That is how kuntai helps customers: providing strong, smart choices for every job.

What Makes Steel the Top Material for Commercial Garage Door Braces?

When it comes to commercial garage door braces, steel is by far the best material to use. This is because steel is very strong and can handle a lot of weight and pressure. Commercial garage doors are usually large and heavy, so the braces that support them need to be tough. Steel provides the strength needed to keep the door secure and working properly for a long time. Another reason steel is popular is because it does not easily bend or break. This means that even if strong winds, heavy rain, or other weather problems happen, steel braces will still hold the door in place. They help protect the garage and everything inside it. Also, steel can last a long time without needing to be replaced. This makes it a good choice for businesses that want to save money in the long run. At kuntai, we use high-quality steel in all our commercial garage door braces to make sure they are strong and durable. Steel can also be treated to resist rust and corrosion, which is important because garage doors are often outside and exposed to rain and moisture. Without this protection, metal parts could become weak and unsafe. Steel braces from kuntai are made with special coatings that keep them safe from rust for many years. All of these reasons make steel the top material for commercial garage door braces. It is strong, long-lasting, and able to protect your commercial space well. When you choose garage door braces made from steel by kuntai, you are getting a product that can handle tough conditions and keep your doors safe and working smoothly.

What Common Material Issues Should Wholesale Buyers Avoid in Garage Door Braces?

When buying garage door braces in bulk, wholesale buyers need to be very careful about the materials used. Many problems can happen if the wrong materials are chosen. One common issue is using low-quality metal that is not strong enough. Some braces might look good at first, but if the metal is thin or weak, the braces can bend or break easily. This puts the whole garage door at risk of falling or getting damaged. Another problem is poor rust resistance. If the metal is not properly treated or coated, it can rust quickly. Rust weakens the metal and makes it unsafe. Wholesale buyers should avoid braces made from metals that do not have strong protection against rust. At kuntai, we make sure every brace is coated with the best rust-resistant materials so they last longer and stay safe. Some braces are also made with metal that has many impurities or poor manufacturing quality. This can cause the metal to crack or fail under pressure. Wholesale buyers should check for signs of poor metal quality, like uneven surfaces or rough edges. These signs may mean the metal is not good enough for commercial use. Another issue is choosing materials that are too heavy or too light. Very heavy braces can be hard to install and may put extra stress on the garage door system. On the other hand, braces that are too light might not provide enough support. Finding the right balance is important. Wholesale buyers should work with trusted companies like kuntai that test their materials carefully to provide braces that are just the right weight and strength. Lastly, some braces may have poor welding or joining methods. Even if the metal is strong, weak welds can cause the brace to break. Wholesale buyers should ask about the welding quality and make sure the braces are made with strong, reliable connections. Avoiding these common material issues helps buyers get braces that keep commercial garage doors safe and working well. By choosing braces made from high-quality steel with good rust protection and strong welds, like those from kuntai, wholesale buyers can avoid many problems and protect their investment.

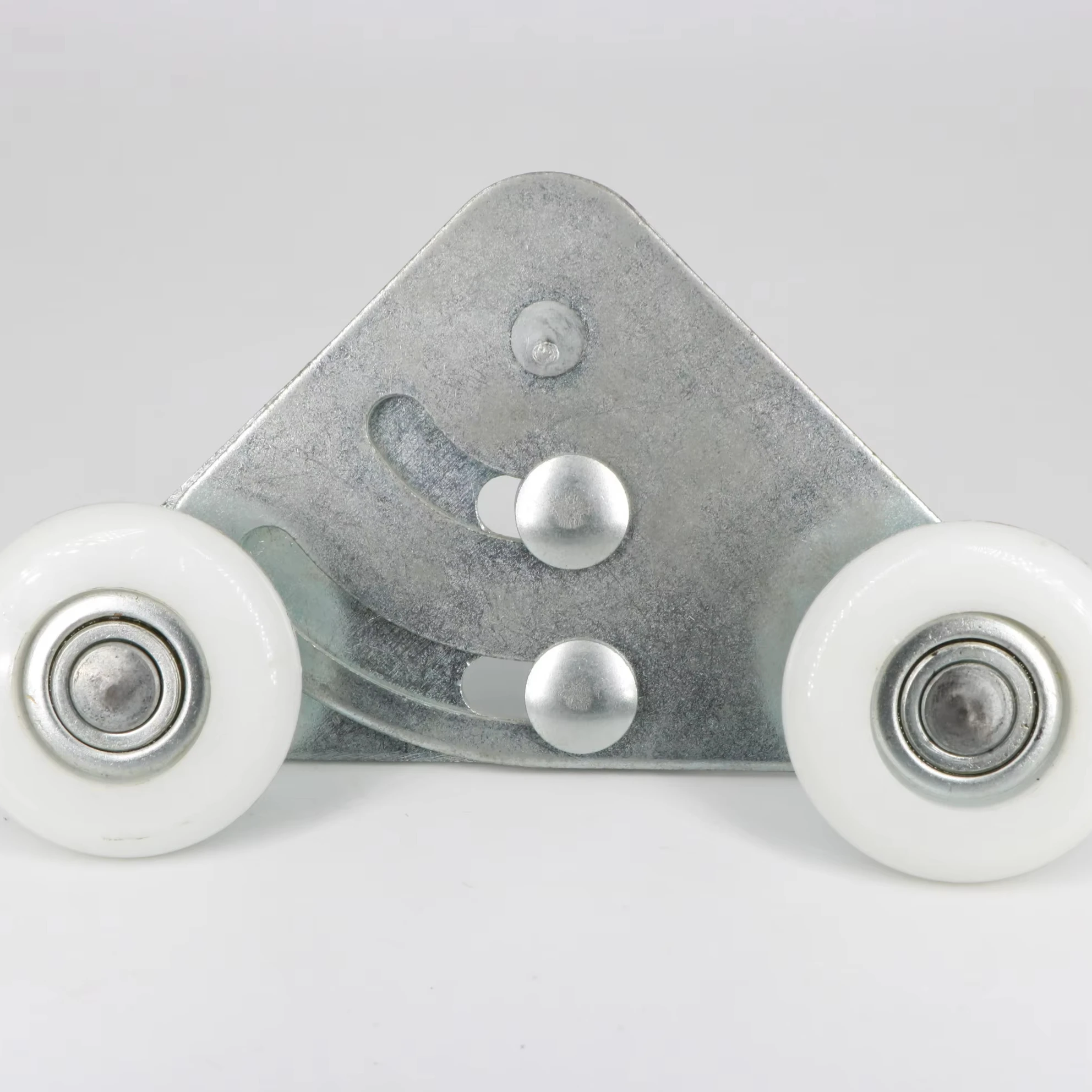

How to Identify Superior Material Quality in Wholesale Commercial Garage Door Braces

Knowing how to spot high-quality materials in wholesale commercial garage door braces is very important. Buyers want to make sure they get braces that will last and do a good job. One way to identify superior material quality is by checking the type of metal used. The best braces are made from strong steel that is thick enough to handle heavy loads. If the metal feels too thin or light, it might not be good quality. At kuntai, we use only thick, strong steel for our braces to ensure they can support big commercial doors. Another way is to look at the surface of the braces. High-quality garage door brace braces have smooth, even surfaces without dents, scratches, or rough spots. These imperfections could mean the metal is weak or not properly processed. Good quality braces also have a clean and even coating that protects against rust. You can often see this as a shiny or matte finish that covers the entire brace. The coating should be smooth and not peeling or flaking. Kuntai’s braces are coated carefully to keep rust away for many years. A third way to check quality is to ask about the manufacturing process. Superior braces are made using modern machines and strict quality controls. This helps make sure each brace is the same size, shape, and strength. You can ask the supplier for garage door panel brace certificates or test results that show the metal’s strength and durability. Kuntai provides these documents to prove the quality of our garage door braces. Also, look closely at the welding or joints where parts are connected. Good quality braces have clean, strong welds without cracks or gaps. Poor welds can cause the brace to break under pressure. Kuntai uses advanced welding techniques to make sure every brace is strong and safe. Finally, buyers can sometimes test the braces themselves. Simple tests like bending or tapping the metal can show if it feels solid Hinges & Brackets or weak. High-quality steel sounds firm and does not bend easily. By using these tips, wholesale buyers can identify superior material quality in commercial garage door braces. Choosing braces made from strong steel, with smooth surfaces, good coatings, and strong welds, like those from kuntai, helps ensure the garage doors will be safe, durable, and reliable for many years.