@xyerraaa08

- Followers 0

- Following 0

- Updates 272

Microchannel Heat Sink Technology: Advancements via Precision Extrusion

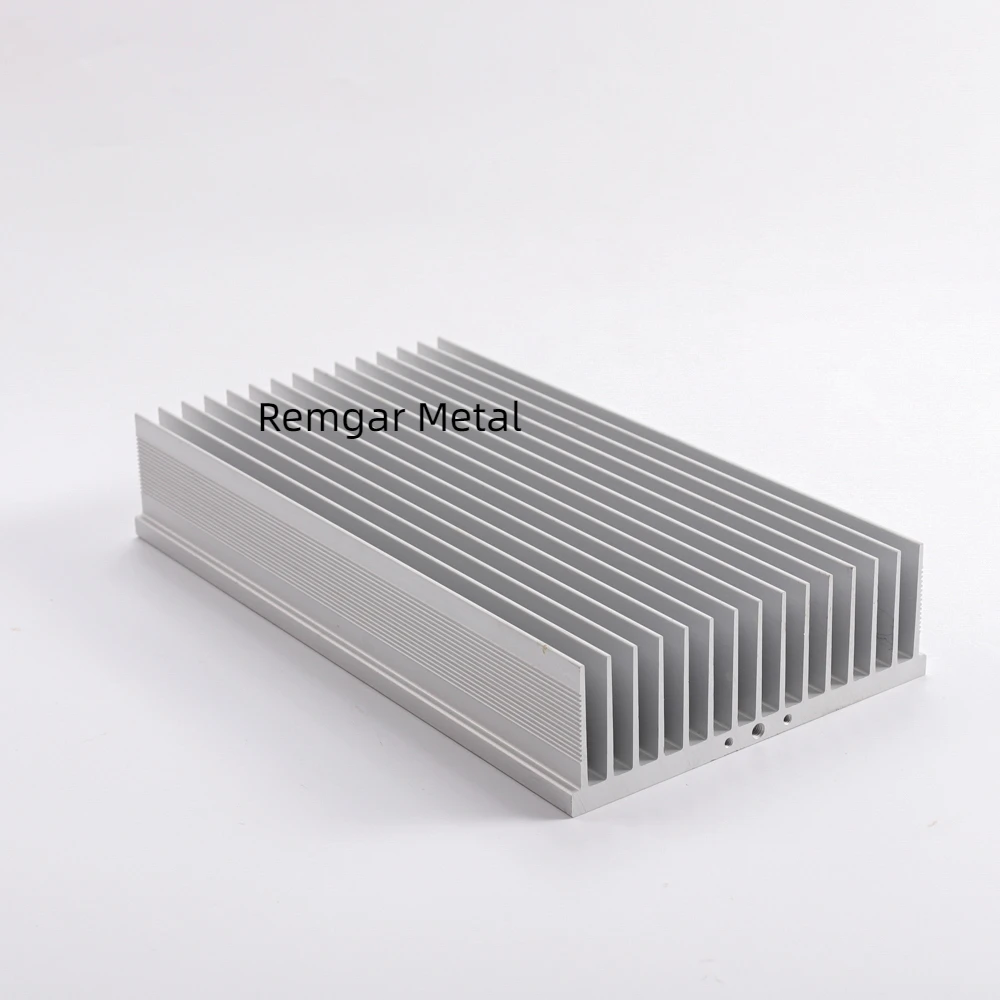

If you’ve used a computer or laptop, you’ve probably noticed that the newest technology keeps getting better and better, particularly when it comes to the gadgets keeping all those electronic devices cool. One of the most interesting improvements in cooling technology is microchannel heat sink technology. But what is a heat sink? A heat sink is a type of hardware used to help electronic devices run cooler by removing heat from them. Microchannel heat sink technology takes this idea of a heat sink and employs tiny “micro” channels to assist dissipate heat. Microchannel heat sink technology works by incorporating thousands of small channels within the heat sinks. These channels allow the heat to spread more evenly and produce a great amount of cool airflow across the heatsink. The smaller the channels, the more surface there is for the heat to dissipate, resulting in more effective cooling. As a result, a heat sink using microchannel technology keeps a device cooler for more extended periods, increasing its life expectancy and contributing to enhanced performance. Precision extrusions enable the design of very specific, thorough contours. This is exactly what is required when designing tiny channels in an aluminum heat sink. These tight controls enable precise requirements control over flow, which promotes improved cooling. Utilizing precision extraction for your heat sink components allows the creation of device-specific designs, ensuring the best matching.

This is exactly what is required when designing tiny channels in an aluminum heat sink. These tight controls enable precise requirements control over flow, which promotes improved cooling. Utilizing precision extraction for your heat sink components allows the creation of device-specific designs, ensuring the best matching.

Advances in Microchannel Technology for Improved Thermal Management

Overheating can cause devices to slow down, or even stop functioning entirely. Enter thermal management – everything is about keeping the temperature low heat sink manufacturer so it keeps running flawlessly. With microchannel technology, thermal management is even more streamlined by facilitating cooler operation. The small channels and precision design of microchannel heat sinks can enable devices to perform at their peak temperature, avoiding overheating which affects the performance speed.

PREMIUM QUALITY EXTRUSION FOR SUPERIOR HEAT SINKS

When to use a Precision Extrusion for Heat Sink Fabrication This custom heatsink manufacturer makes precise calibration and improved thermal cooling performance possible in heat sink designs. Additionally, precision extrusion can create different shapes and sizes of heat sinks that make the process more convenient for several electronic devices. When it comes to thermal management, this level of customization means that each heat sink is optimized for its unique cooling application.

ADVANCING COOLING SYSTEMS WITH MICROCHANNEL TECHNOLOGY

With the continued advances in technology, this need will only grow. Microchannel Heat Sinks technology will play an ideal role in the cooling systems which are useful for high performance and thermal management of electronic devices. As aluminium heat sink manufacturers heat sinks continue to evolve with the help of precision extrusion, it is highly likely that we can look forward to more sophisticated and stronger cooling solutions in the coming years. Remgar is a leader in this exciting new technology, driving the future of cooling systems through experience and precision.