@xyerraaa08

- Followers 0

- Following 0

- Updates 272

Blog

Innovations in Juice Bottling Lines: Technology to Maintain Flavor and Nutrients

By xyerraaa08, 2025-09-05

Juice Bottling Lines with the Latest Technology

Today juice bottling lines use highly innovative technologies to keep the flavor and key nutrients of the juice from the moment it is bottled up until it reaches customers. These advances in technology have dramatically changed the way juice is packaged and preserved, creating a healthier and tastier range of products for stores everywhere.

Recent Developments In Juice Packaging

That means not every latest innovation in juice packaging can ignore the use of aseptic filling technology. The process consists of sterilizing separately the juice and all materials in contact with it, so as to pack bottles or aseptic bags under a sterile environment. This is done to make sure the juice does not encounter any bad bacteria and other contaminants, staying fresh for a long time without having to lose its essence and nutrients.

Technology has made a lot of transformation in juice bottling process

The juice bottling process has been automated in many ways, thanks to technology in revolutionizing packaging for the juice. Bottles are filled, capped, labelled and packed by automated systems at a faster pace than human labour reducing the chances of contamination. This not only saves time and money but also 100% guarantees fresh juice containing 2 essential nutrients in the bottle.

Science of Retaining Flavor and Nutrients in Juice Bottles

This is because all of the flavor and nutrients in the juice is molecularly bonded to everything else, so turning it into powder without anything getting lost in Juice hot filling line the extraction process requires precise attention to detail. The modern juice bottling lines have quite a number of sophisticated processing methods with flash pasteurization, and cold pressed processes being the most popular due to their ability to retain both flavors as well as the nutrients contained in the juice. The juice is immediately heated quickly (flash pasteurization) to kill harmful bacteria without affecting the flavor or nutrient density. The process of extracting juice from fruits or vegetables without really using any heat, which is what can start to kill off a lot of the nutrients, this type of juicing is called cold pressing instead.

Improve the Juice Bottling Technology for Better Nutrients and Flavor

Juice bottling technology has come a long way since then, but Juice filling machine efforts to keep all of the juicey-ness in one place have led to new methods that help maintain the maximum flavor and nutritional benefits available. For instance, some juice bottling lines now start with nitrogen flushing to drive oxygen out of the bottles before they are capped. This slows oxidation, which can cause the juice to lose nutritional value and flavor. Other innovations will involve making use of UV light treatment to Slap Attack any remaining bacteria and extend the shelf-life without added preservatives.

The essence and nutrients of juice on modern day juice bottling lines have increased a lot. The same goes for how juice is preserved and processed, but thanks to these innovations incorporating new processes in juice packaging and preservation process that have made the change in the industry which has in turn facilitated better products towards consumers. Juice bottling lines rely on state-of-the-art technology and science-based methods to ensure the juice conserves its freshness and nutritious content from time of bottling till consumed.

High-Speed Juice Bottling Lines: Meeting Demand for Popular Juice Products

By xyerraaa08, 2025-09-04

Do you ever marvel over how your most loved juice items are created so quick and efficiently? At least, that has something to do with high speed juice bottling lines! Machines like these awesome ones allow companies such as Modern to handle the high call for some of the most popular juice products. In this article, we turn our attention onto these bottling lines and how they not only work but have helped juice manufacturers live up to what consumers have expected.

So Fast, you buyers are keeping up with the distribution of your favorite juice products…..

With such a high demand for the juice products, Modern has to produce thousands and thousands of bottles in a very short period. This is what fast bottling lines are capable of. They bring and seal hundreds of bottles each moment making sure the shelves are ever filled with your beloved juice. Companies would barely be able to produce consumer favorite juice products without these high-speed bottling lines.

High-speed juice bottling tech:

High-speed juice bottling lines employ sophisticated technology to enable a rapid and efficient operation. Those canning machines have conveyor belts that carry the bottles through the assembly line to be filled with juice, capped and labeled. Computer systems manipulate the entire process that occurs for a large period of time. It is this type of technology that allows Modern and partners to produce premium juices at a high speed.

Living up to consumer expectation promptly by a established assembly line:-

Customers expect their precious juice bottles to be in stock whenever they crave for one. Modern and the high-speed bottling lines also ensure that juice products are always in stock. They provide the makers to comply with the demand of popular juices, and keep their production line on a fast track. This way, consumers are always able to find their preferred juice products on the shelves.

The following article details how automated processes streamline juice bottling operations and boost efficiency.

High-Speed Bottling line is One of the major advantages which it carries with itself is its fully automatic functioning. This implies, from start to finish production is managed by the machines taking away the application of manual work thereby giving greater productivity. Modern and similar companies employ automated processes to help handle the large number of juice products they produce quickly and in a more standardized way. This Beer bottling line also makes certain that each and every bottle of juice produced from that line is manufactured at the highest standard.

How juice makers keep up with evolving trends and market demands thanks to high-speed bottling lines

Trends also change from time to time as consumer preferences change frequently and companies must develop the ability to act on these changes at pace. Bottling at high speeds ensures that juice manufacturers can be nimble; bottling allows for swift production of different products and variations in response to consumer demand. For Water bottling plant companies like Modern, they have used these machines to add multiple new flavors and packaging sizes to cater to their customers.

Ultimately, high-speed juice bottling lines such as the ones Modern operates enable them to meet incredibly high demand for some of the most sought-after juice products on customer shelves today. These Juice hot filling line machines make use of high-end technology and automates process that allows juice manufacturers to produce quality products at a fast pace with less human intervention. High-speed bottling lines are an incredible way to keep pace with consumer demand, and they enable businesses to stay ahead of the constantly changing currents associated with the ebb and flow of trends. The next time you are experiencing a glass of juice, oh so refreshing, remember thank those high-speed bottling lines that made it happen!

Juice Bottling Line Labeling: Ensuring Compliance with Nutritional Information

By xyerraaa08, 2025-09-04

The juice bottles that your favorite Modern brand juice comes in looks like something you totally should be drinking, have these words and numbers printed out on them. Labels designate what the juice is made of and why it is beneficial for you!, we explain: everything about juice bottling lines and interest of this nutritional info on its labels.

Making Sure You Have Accurate Nutritional Labeling

If you grab a bottle of juice from the store, there are numbers — calories, sugar, vitamins. These numbers are crucial as they indicate to you about how good the juice is for your body. For instance, if you notice that one juice has a great deal of sugar in it then maybe you drink that juice too frequently because an excessive amount of sugar is bad for you.

Using the best labeling practices on juice bottles

In order to ensure that juice labels accurately depict their nutritional information, juice bottling lines will need to make sure they are following the best practices when it comes to using labels. That is by selecting appropriate fonts and sizes for the words and numbers on the label, making them readable. This also indicates that the data has to be written on the bottle so it is easily visible thus enabling customers to decide quickly what ingredients are found in this juice.

Complying with governmental nutritional information initiatives

As well as, juice bottling lines also have to make sure that they're adhering to government stipulations set for nutritional data. The government decides the rules and guidelines about what is needed to be written on food and drink labels ensuring that customers get the information they need such as calorie count, number of portions etc. Adherence to the FDA regulations enables juice bottling lines to provide labels that are both accurate and truly reliable.

Improving juice bottling line Labeling process

Indeed, even the way toward naming juice containers can be preposterous if there are various flavors and sizes. Technology is available to streamline labeling, allowing the myriad juice bottling lines to get more juices in more ways. They do this by using machines that print labels directly onto bottles at fast speeds and with high accuracy, so they have the right nutritional information on each one.

Transparency about nutrition content featured on juice labels to satisfy consumer demand.

In 2021, consumers Bottle labelling machine are even more health conscious and careful about what they then put into their bodies. Thus, it is crucial that juice bottling lines accommodate the consumer demand for repeatability in nutritional content on labels. Juice bottling lines who share detailed, easy-to-read information on their juice bottles establish a sense of trust with the consumer and a foundation to believe that they offer healthier options.

So the final answer, is that correct nutritional labeling on juice bottles must be done to give one a clear picture of what they are drinking. Best practices, government regulations, simplifying labeling and transparency demands from the consumer all make sure that juice bottling lines keep their customers informed in order to allow them to live healthy lifestyles.

The next time you buy a bottle of the your favorite Modern brand juice simply look at the label and see for yourself what type of nutrients there are in this fantastic tasting vitamin and mineral enriched drink. I also think you will be shocked how much you can learn about what is in that yummy drink!

Juice Bottling Line for Small Producers: Compact Systems for Artisanal Brands

By xyerraaa08, 2025-09-04

As someone who makes and sells tasty juices on a small scale, you understand the importance of having equipment that is easy to use when it comes to bottling your delicious drinks. That's where Modern comes in! Our small juice bottling line is ideal for the emerging artisanal brand like yours. Keep up and learn how our new production technology can contribute to higher quality and a more efficient juice output in the following long read.

Small Batch Juice Productionplatfrom

When you are preparing small batches of juice any drop is worth. That's where our juice bottling line comes in, built to bring efficiency to your production process as you fill, cap and label bottles with precision. Say Goodbye to Messy Spills and Hello to Ready-to-Go Juices With Our System

An answer for Artisanal Juice Producers

As an artisanal juice maker, you are proud of the product that goes into your bottles. No matter what specific requirements a brand like yours may have, our juice bottling line can be your ideal solution for quick and easy bottling of some wonderful creations. Our bottled line can be used to pre-package many different liquids, like hand-pressed apple juice or cold-pressed green juices.

The Latest Technology for Craft Juice Bottling

At Modern, we believe that technology can be instrumental in enabling small-scale producers to thrive. Lucky for you, we have implemented the most up-to-date features to our juice bottling line that is sure to make your customers pick up, never build a barrier so they simply can't refrain from. With our system, you Beer bottling line are making the leap to automatic filling and capping, customizable labeling options and many more which are need of your juice production.

Cost-effective Juice Filling System

We know that you are a small producer so we understand that you need high quality but still affordable equipment. That is precisely why our juice bottling line has been designed where you get quality Water bottling plant at a cost effective price. Fill your carafes of juice and you can do it without getting out the checkbook a bunch of times.

Boosting Quality and Efficiency for Boutique Juice Brands

Your juice bottling line is the backbone of your juice brand so it needs to be efficient and high-quality for you to have a successful juice brand. Using our small system you will be able to further elevate the quality of your juices and in larger quantities, efficiency. Modern will take your small juice brand right up there with the heavy weights.

In summary, the juice bottling line from Modern is ideal as small scale production Juice hot filling line equipment and aids in improving quality of artisanal juices produced. Our compact line is designed to help you succeed with cutting-edge technology, efficient systems and affordable options. So why wait? Get more out of your juice production with Modern and simplify how you bottle your amazing creations today!

Quality Control in Water Bottling Plants: Testing and Monitoring Protocols

By xyerraaa08, 2025-09-04

Ensuring that things are safe and good [Quality assurance] This is particularly sensitive in water bottling plants, where they use it for ensuring that the water you drink contains no bad ingredients. Cans have been designed specifically so that each can has a specific testing and monitoring protocols in place to ensure the water inside is safe to drink. Get a deeper insight into how water goes through the water bottling plant to ensure that it is fit before reaching us.

Why Are Strict Quality Control Measures at Water Bottling Plants So Important?

Water bottling plants have strict quality controls in place. They want to ensure that the water they place in them is clean and free of contaminants that are dangerous to human health. And to achieve this they are playing by the book of rules and testing the water on every single step. This is to catch any problems before the water gets into the bottles.

The role of testing and monitoring protocols in maintaining the purity of bottled water

Test and monitoring protocols are the special tools you would see in place at water bottling plants to control the quality of the water being bottled. They test the pH level, bacteria levels, and any chemicals in water. This way, the plants can ensure the water is healthy for you to drink. It is how they maintain the purity of the bottled water.

Why must water bottling plants abide by rigorous regulations in terms of quality control

Water bottling plants follow Water bottling plant take stringent regulatory approaches to make the water safe. They need the approval of permits and licenses. And they must report every test they perform on the water. To make it look as though they are complying and ensuring the safety of everyone in the water.

Step-by-Step: The Water Journey In Bottling Plants Through Testing And Monitoring Processes

Before the water is accepted into the plant, it is run through a battery of on-line analyzers to check for things like solid content (suspended solids), pH, spent dyebath color, flow, etc. They first verify where the water is coming from to ensure that it can be safely used. They then pass the filtered water through a filter to remove the dirt. They then check the amount of bacteria, and chemicals that are in there. Then, they bottle that water and ship it out to sell you.

The transparent quality control practices that foster trust in bottled water products

Water bottling plants earn customer trust by virtue of the transparency in their quality control practices. It shows that you take precautions to purify your water. People believe that the water in the bottle or containers is good for them. When you encounter Modem water, you can assure that it is well-processed and monitored to avoid any health risks associated with the Lisp pollution.

Hydraulic components, corrosion resistance is a must! It helps maintain their quality overtime. Rusted or corroded hydraulic components may not function or worse yet they will break down. It can create the hudge loss and money spent behind to resolve. So one of the main reasons you have to consider when buying hydraulic components is corrosion resistance. The post What Are Your Values and Why They Are So Important to Know More About appeared first on Dr. SCHAUFELEXIT.

The Importance of Corrosion Resistant Hydraulic Components

Highly Corrosion Resistance: Hydraulic components including pumps, cylinders, valves, and hoses are exposed to different types of environmental conditions. Valves are components, or devices that have lids, which allow the flow of liquids in machines and vehicles to be controlled. But if they get rusty or corroded, they won't operate properly. This feature not only preserves structural components but also shields them against rusting and other damaging agents (by which I mean, oxidation). This will help ensure they function and endure for years to come.

Corrosion Resistance: The Need of the Hour

Corrosion is a natural process that occurs when metal materials are going to be in contact with water, air, and other substance. This can soften the metal, making it more sensitive to breaking or failing. Corrosion resistance: ability for a material to withstand corrosion. They are chosen for hydraulic components as they are not susceptible to rust or corrosion, materials with high corrosion resistance. When we realize how important it is for corrosion resistance, then we could use the correct material to avoid a poor-performance auxilary items & system.

Why Is Corrosion Resistance for Hydraulic Components Important? Hydraulic components are exposed to various elements, including moisture, chemicals, and high pressure. When they lack adequate corrosion resistance, the components can degrade quickly, thus leading to leaks, failure, and malfunctioning. Additionally, the corrosion damages the hydraulic fluid, which significantly undermines the operation of the system. However, when corrosion resistance is prioritized in their design and maintenance, the components are safe from damage, and their lifespan hydraulic cylinder for dump truck is extended, and the chances of costly repair and replacement reduced. What Are Some of the Impacts of Corrosion Resistance on Hydraulic Systems? Corrosion resistance is a function of the overall effects of hydraulic systems on hydraulic systems. If the components are made with a low corrosion resistance material, they are bound to suffer immediate attack and damage. These attacks cause the hydraulic systems to report leaks, less efficiency, and possible safety hazards. When material and coatings that are resistant to corrosion are used, they ensure the smooth operation of hydraulic equipment. This not only increases the life of machinery but the operation is also safe and dependable. Why 5 stage telescopic hydraulic cylinder for dump truck Is Corrosion Important in The Functionality of Hydraulic Components? The functionality of hydraulic components is core to the functioning of machinery and equipment. It is because corrosion resistance ensures that rust and corrosion are kept away. It means enhanced corrosion resistance technology such as stainless steel, coatings, seals, etc. ensures hydraulic components highly intact and operational for longer. It means the equipment will experience fewer downtimes, less repair and replacement – saving time and maximizing return on investment.

To sum up, corrosion resistance is indispensable to maintenance, life cycle and security of hydraulic components. Hydrauloslugs 4 stage dump truck cylinder can help keep your hydraulic hygienfal and functioning for the long term by providing corrosion protection in a controlled environment. Junfu hydraulic is applied corrosion resistance to the design and production of its hydraulic components,providing better quality and workmanship than anyone.Compare our prices! AND HYDRAULIC LIFE CYCLE Improving the lifespan of our customers hydraulic systems, through investment in corrosion resistant materials and technology.

Maximize Throughput with Rotary Dryers from Shandong Tianli Energy Co., Ltd

By xyerraaa08, 2025-08-16

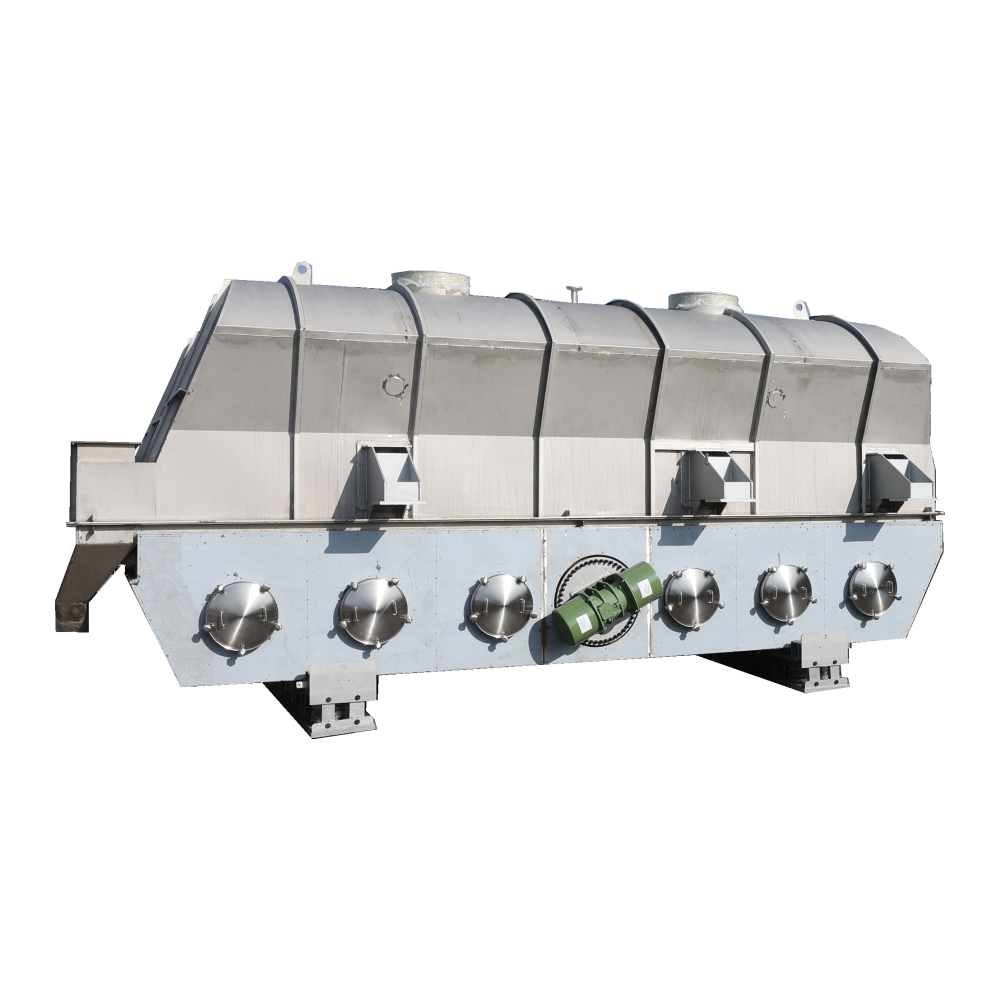

Rotary Dryers for Improved Productivity

The rotary dryers are basically machines and help a lot in drying of large materials for the industry. They operate by revolving various types of materials in a spinning drum as heated air passes through, driving away moisture and drying the materials. Rotary dryers can allow businesses to boost their production capacity and efficiency per hour, per day, or for a certain timeframe.

Maximize Your Processes with The Rotary Dryers of Shandong Tianli Energy Co., Ltd

Shandong Tianli Energy Co., Ltd — Leading Manufacturer In Rotary Dryers To Improve Your Operation Gardus — Our rotary dryers are made of high quality materials, and we design them to last. With the help of our rotary dryers, you can count on a faster, custom tailored process to your drying needs.

High Capacity Rotary Dryers for Maximum Output achieved

If you want to get max output for your business then you must use rotary dryers from Shandong Tianli Energy Co., Ltd. We fabricate rotary dryers that allow for quick and efficient disposal of large quantities of materials after the drying process. Our rotary dryers will solve your problem here, as rotary dryer they are ideal for all types of industrial plants with minimum maintenance and affordable quality provides high productivity so that you can full Fertri in line with the demand queue:-

Dryer Optimization for Productivity and Profitability (by Shandong Tianli Energy Co., Ltd.)

Shandong Tianli Energy Co., Ltd's rotary dryers can help take the quality of your enterprise up a notch, thereby increasing productivity and profits. With rotary dryer, you can count on having precision-engineering and system that is capable to work efficiently and smoothly. Our rotary dryers reduce downtime and increase output, allowing rotary steam tube dryer you to spend more time fishing- not processing.

Shandong Tianli Energy Co., Ltd: Rotary Dryers that are Making your Drying Process a Breeze

Rotary dryer of Shandong Tianli Energy Co., Ltd can help you, our rotary dryer is specially designed to optimize your drying process and enhance production efficiency. Our rotary dryers come with intricate features for controlling temperature, airflow and drying time. Let our rotary dryers reduce waste and improve quality of your end products.

To sum up, if you are looking to increase the productivity and efficiency of your operations, rotary dryers rotary steam dryer from shandong tianli energy co.ltd. is a perfect option for your industry. Our premium rotary dryers enable you to: produce more with less, do the job right the first time, gain energy and maintenance savings, maximize output capacity, improve productivity and profitability and reduce downtime. Get yourself a Shandong Tianli Energy Co., Ltd rotary dryers today and elevate your business.

If you are searching for a supplier to supply with the right strapping rolls so that it helps you in packaging immunely. Then you come to the right place by Enjoy Packaging! We realize how daunting a task researching for the right custom strapping roll sourcing supplier can be, and that is why we make every effort to simplify it in terms of cost of time and money so you do not have to waste unnecessary frustration comparing other companies.

Efficient Strapping Roll Procurement Solution

When you are looking for strapping rolls to cater your packaging requirements, then you must be sure that the quality of products supplied is top gear and prices should be competitive too. By working with our reliable and trusted supplier, Enjoy Packaging, you can simplify your sourcing process by directly getting the custom strapping rolls that you require. Our expert team will first analyze and then listen to what your needs are give best solutions for packing.

Developing Robust Relationships with Custom Strapping Manufacturers

We personally take care of the needs of our customers and this is why we, at Enjoy Packaging, believe in forging lasting partnerships with those around us. Together with your help we learn more about what you really need, allowing us to develop customized solutions that are exactly the right fit for you. We seek to make you effective and efficient by custom strapping rolls with our supplier partnerships. By forming a partnership with Enjoy Packaging, you can feel confident that you have a team of professionals dedicated to your business.

Reducing Complexity in Your Supply Chain with Custom Strapping Roll Sourcing

Managing Your Supply Chain Can Be a Headache Enjoy Packaging is here to streamline your supply chain; offering you all of the custom strapping rolls that your company relies on in one convenient location. It is a more targeted procurement process that allows you to find the products quickly whenever you need them, this way saving your time and resources. Have any type of Strapping Roll requirements, We are the one stop solution provider for all your needs from Tapes to Corrugated boxes we provide simplified supply chain solutions to make your business easy.

Customized Strapping Roll Solutions

We provide custom solutions for your strapping roll needs as every business is unique and has its packaging demands. Enjoy Packaging offers custom sizes, colors Strapping roll and materials so you can pack your goods with care Our team of professionals is committed to providing you better strapping roll solutions and this in return help you package products with peace-of-mind.

Improving Speed and Evenness by Working with Custom Strapping Roll Suppliers

When it comes to your custom strapping roll needs be sure to PP strapping partner with Enjoy Packaging to help improve efficiency and quality in your packaging process. We have devised a list of goods tailored for your unique demands and our experts will work closely with you throughout the entire process. The difference between Proofgrade materials and additives you buy on the side are that our suppliers provide long-lasting products that can be trusted to last and achieve competitive results. Enjoy Packaging Can Offer the Perfect Solution for Custom Strapping Rolls With Our Streamlined Practice.

To sum up it all, you can feel free to rest your faith in Enjoy Packaging as the ultimate provider of custom PET strapping strapping rolls. Our fast time-to-market, strategic partnerships and personalized solutions can streamline your packaging services to improve operations and logistics efficiencies. Reach out to us today and learn how we can relieve you of your packaging requirements through our tailored strapping roll products.