@traspino

- Followers 0

- Following 0

- Updates 338

Category: 7 Costly Mistakes to Avoid in Secant Pile Wall Construction

What are the advantages of JWELL High-speed Energy-saving Pipe Extrusion Line?

By traspino, 2025-08-11

These days, technology goes a long way in making our lives more convenient and streamlined. JWELL Machinery is a professional machinery manufacturer and suppliers of various extrusion and injection machines. Some of their best-selling products include the JWELL High-speed Energy-saving Jwell HDPE630 pipe extrusion line machinery . This amazing machine comes with many benefits that put it at the top of the list for manufacturers worldwide.

Upgraded output performance with fast extrusion speed

The JWELL High-speed Energy-saving Pipe Extrusion Line is not only a cost effective choice, but it increases output as well. What this means is that a manufacturer will be able to create more pipes in less time, resulting in increased productivity and profit. This machine is high speed and allows companies to handle more jobs faster, no making the impending deadline a tough thing to meet without sacrificing quality.

This results in high energy saving and economic production options.

Besides fast production speed, the JWELL High-speed Energy-saving Pipe Extrusion Line can save lot of energy. The machine includes energy-efficient elements that contribute to lowered power consumption during extrusion. Manufacturers can spend less on their utility bills and be more environmentally friendly by using less energy. It is a very economical machine for companies wanting to save money and boost their profits.

Tight quality control ensures superior product performance.

Nothing matters more in the production of pipe than quality, says the Jwell High-speed Energy-saving corrugated pipe extrusion line . This is a machine that has beendesigned to constructpipes with high quality standards. Its rigorous extrusion process guarantees that each pipe is manufactured to the highest quality industry standards for performance and strength. When customers receive a product from themselves, they have confidence that the end user will be satisfied and come back for more.

Increased user friendliness for operation and maintenance.

The JWELL High-speed Energy-saving Pipe Extrusion Line has another advantage of human-centrifugal designed. This equipment is user-friendly; the operation buttons help the operators tune the parameters and follow up with production all the time. Also, keeping it in working order is simplified with the easy principles and simple instructions. With its facilitation of operation and maintenance, JWELL has developed the machine for manufacturers as its aim to maximize uptime and reduce downtime.

Sustainability Green design for sustainable manufacturing process.

Last but not least, the JWELL High-speed Energy-saving Pipe Extrusion Line incorporates an environmentally friendly design for a sustainable manufacturing process. Built from 100% recycled materials, environmental friendly, save the planet, save more with a good conscience clean this machine is energy efficient and it will save our planet. With the JWELL High-speed Energy-saving Pipe Extrusion Line, manufacturers can lower their carbon footprints and add to the sustainability of a cleaner future for the next generation.

Finally, the JWELL High-speed Energy-saving double wall corrugated pipe extrusion line is one of the best machines and provides lots of benefits to the manufacturers. With enhanced productivity and energy savings, the machine is a wise downstream option for businesses who wish to achieve higher levels of efficiency of quality in their pipe production. JWELL High-speed Energy-saving Pipe Extrusion Line is well equipped with high-efficient energy saving system, extrusion system with generally customized designs and high-speed immersion cooling bath, which reinforce its performance.

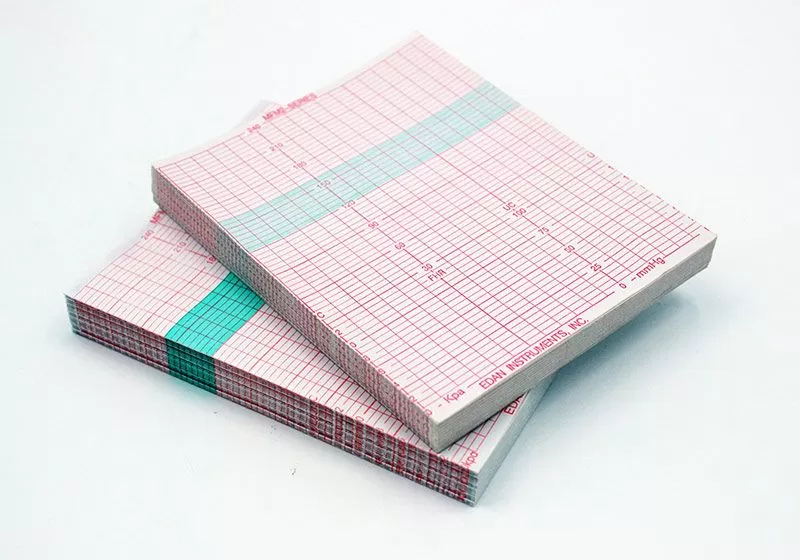

Selecting the appropriate paper for your In-better home ECG machine is essential to ensure readings are delivered and machine operates accurately. The ecg paper you choose to use plays a role in the ECG test you perform, so you want to make sure that you choose compatible paper that is compatible with your particular device.

The importance of selecting the appropriate paper for your home ECG machine

You’ll find that the paper you use is just as important when using your home ecg machine and is one of the key factors in determining the clarity you should hope to achieve. The ECG paper for your ECG machine should be of high quality and compatible to give you reliable readings. The results might be not precise if use paper of wrong type, which will influence for the health management.

Home ECG machine: How to choose the right paper

-

Please check the specifications: before buying paper for your home ECG, please make sure that you can use the paper because the ECG monitor is made by In-better. This will let you find out which type of paper your device will accept, and sizes they print on.

-

Select the right paper: Choose premium thermal paper suitable for hospital use. This paper is heat sensitive and will print crisp ECG tracings resulting in the most accurate readings.

-

Size counts: Make sure the paper you select fits your home ECG machine properly. You really need to have one that is the right size, otherwise your readings won’t be accurate, so make sure to check the size of paper this will require before buying any.

The high paper quality necessary for the accurate ECG measurements at home:

The type of paper that comes with your home ECG paper types machine will be very important in you receiving the proper readings. With your ECG machine you’ll receive the thermal paper you need for the best quality printouts, so that you and your medical professional team members can easily see the fine details of the data.

Preventing common problem, what paper to use for your ECG machine:

-

Avoiding smudging: If using poor-quality paper, you can commonly encounter a smudged print out, which won't be helpful for interpreting ECG results. Selecting premium quality Thermal Paper,you will not have sticky residue, and it will not damage your printer.

-

Compatibility check: Not all home ECG machines are compatible with any type of paper you want to use as you have to consider whether your ECG machine can read the line or scripts well which is why you need to pay attention to that. Please confirm your printer's specifications when using paper other than the supported type.

Here is a complete guide to help you find the right paper for your home ECG device:

-

Research and compare: Did you research different thermal paper that is available to your home ECG machine? Compare paper size, quality and compatibility in form factor to ensure that you are making the right decision for your device.

-

Read customer reviews: Find out what kind of paper to use by reading other In-better home ECG machine user reviews. Thermal Paper Reviews Customer reviews are something, that can be very useful to help ensure that you’re purchasing a high quality and good performance kind of thermal paper.

So when it comes down to it, the quality of your Printable ECG Paper , is an important part of getting accurate readings. With these tips and quality thermal paper, you can easily and effectively perform your ECG tests and manage your health better with clear test resolution. And make sure that you verify the specifications and compatibility of the paper prior to the purchase so that it doesn’t create problem with your machine.

Finding quality green tea for importers: the key to a stable and profitable supply chain

By traspino, 2025-08-11

Green tea is a tasty, healthful drink that many like, myself included. Derived from the leaves of the Camellia sinensis plant, it is famed for its numerous healing qualities. For importers who want to deliver high-quality green tea 41022 for their customers, the search for steady and trustworthy suppliers is important to make sure your supply chain is stable and profitable.

The first step in creating a sustainable importing business is to recognize the significance of sourcing high quality green tea. Good quality green tea is not only richer and more flavorful, it also has more of the healthy antioxidants and nutrients that are responsible for the appeal of true green tea. By selling great green teas, importers can guarantee that their customers are receiving the highest quality product possible.

If you're looking for reliable suppliers of green tea for importing, importers must find suppliers that are credible and can provide them with references of pleased clients. It's also a good idea to go and see the supplier's facilities and their method of production so that you can verify it meets your retail cleanliness needs and high standards of quality. By carefully sourcing suppliers, importers can protect themselves from expensive mistakes and develop a powerful network of reliable partners.

The above points are very important to successful importing of green tea 9371 are few more to successful importing of Green Tea, such as those that give you the edge to provide the market what it needs. Importers will need to have open conversations with their suppliers and communicate product quality and standard delivery terms. Importers should keep the lines of communication open and file reports when problems occur, because they can then take immediate action to guarantee that their customers consistently receive quality green tea.

Keeping profitable with a rich network of green tea growers is also the key to be prosperous importing business. Because importers work with a variety of producers, they can leverage different growing regions and harvest times to provide a continuous supply of green tea year-round. This can help importers to avert shortfalls and price swings that can affect their bottom line.

To assist importers in establishing a solid and profitable green tea supply chain here is: What you should know when sourcing green tea 1.

-

Establish an excellent rapport with your suppliers and keep in regular touch in order to discuss any problems that come up.

-

Expand your network of green tea producing farms so that you always have a steady supply of quality product.

-

Track your suppliers' performance, and be ready to switch if product quality and dependability suffer.

-

Keep up to date on trends and what your customers are looking for so you do not waste materials on products that will not sell.

-

Always be on the search for new supplier or producer opportunities to better grow your network and mitigate the chance of supply chain hiccups.

By adhering to the above tips and working closely with suppliers, importers are able to create a robust, profitable excellent green tea supply chain that is sure to satisfy customers and promote business expansion. Hongda Tea gives 100% to importers to ensure the best green tea product in order to for the importer to have a copetitive and sustaining bussiness.

Air Compressor Air End An air compressor air end is a significant component of air compressor machinery. It makes the air compressor function in order to produce Portable Air Compressor , and can be utilized in various things.

What is an Air Compressor Air End

The air end is the actual component of the air compressor that compresses the air. It's comprised of a bunch of various parts all working together to take in air and compress it into a smaller space. So with this, the air comes out a little bit stronger and you can even use it to power tools, to inflate tires and so on.

Air Compressor Air Ends An Inside Look At What Makes an Air Compressor Air End Work

An air end is a complex assembly consisting of numerous elements that are compressed and sucked air and then it is passed to the rest of the compressor and stored as energy.

The Portable Air Compressor air end consists of different parts that are doing tasks as a unit to effect the air compression. These are the compressor pump, the motor, the cooling system, and the control or operating system. All of these pieces are crucial for ensuring the air compressor is functioning properly and efficiently.

How does Air Compressor Air End Work

When you trigger the switch on an air compressor, the motor is “turned on” and the pump is turned on as well. From the atmosphere, the compressor pump draws air into itself and shoves it into a small space. When the air is compressed, it becomes hotter, and a cooling system helps keep it cool. When the air is sufficiently compressed, it is held in a tank until it is required.

Why the Quality of the Air Compressor Air End Matters

The air compressor air end is very important to have high quality because it guarantees the air compressor works effectively and efficiently.The ability to compress the air fast and efficiently at low energy consumption. This can serve to save on electricity and help ensure that the air compressor does not breakdown anytime soon.

How to Take Good Care of Your Air Compressor Air End

In order to maintain the air end of your air compressor in run-to-shape, you need to inspect and service it frequently. This may be an oil change, getting the cooling system cleaned, and ensuring all the parts are operating. You can help your air compressor air end to last longer and work better, giving you the compressed air you need when you need it, by taking care of it.

Finally, an air compressor air end is an essential component for an air compressor. It does so, by compressing air with many parts cooperating with each other. When you understand how it operates and maintain it properly, you can ensure your air compressor will serve you well for years to come.

Basic PET Sheet Extrusion Fundamentals

PET sheet extrusion is the process of heating and shaping plastic material into thin sheets. These sheets are widely used in packaging, printing and allied industries. The procedure requires materials to be introduced into a pmma sheet extrusion line , whether they be raw ingredients or recycled products, melted, and formed into flat sheets.

PET Sheet Extrusion Process: Step by Step Guide

The production of PET sheet extrusion die begins with the raw material. The materials are preferably pellets or granules. The materials are next fed into an extruder, which heats and mixes them. The result of this is the molten material being forced through a die to take on its desired shape and thickness. The sheets are cooled and then cut into the required dimensions.

Investigating the PET Sheet Extrusion Line Equipment and Machinery

Important machines for the extrusion of PET film are extruders, dies, and cooling systems. Extruders are machines that heat and blend the raw materials into a molten mass; dies are molds that shape the molten material into sheets of a given size and thickness. The sheets are cooled and hardened with a cooler before being cut.

Quality Assurance in PET Sheet Extrusion

Quality control is a main concern during PET sheet extrusion to obtain proper standards in the sheets. Quality control inspection consists of the temperature and pressure gauge readings on the extruder, the thickness or gauging measurements of the sheets and looking for any defects or response to the gauge. Also, periodically maintenance of the equipment is important to maintain the quality.

Advantages and Uses of PET Extrusions Sheets

There are several advantages to PET sheet extrusion including cost savings, high rates of production, and design versatility. PET sheets are lightweight, impact resistant and offer the clarity of other plastic films, allowing for visual contact and for light to pass through. Such applications are packaging materials, food containers and printing substrates. With a wide selection of PET sheet extrusion line, Jwell satisfies customer's requirements for production.

To summarize, PET plastic sheet extrusion line is a flexible, high-production process with a wide range of applications. Potential young readers will be given an overview of the process, view the equipment and machinery that produce the packaging done for PET, learn proper safety and testing standards within the industry, and finally learn about state of the art technology within the field and why it is important. Jwell is dedicated to providing high-quality PET sheet extrusion solutions to industry demand.

If you’ve ever wondered how anything could withstand extreme heat, you’ll want to take a closer look at the durability of a product titled, Inconel 601 bar and UNS N06600 . This kind of metal, specially engineered to stand up under very high temperatures without breaking down.

Resistance of Inconel 601 Bar to High-temperature Conditioning

Inconel 601 bar is a metal that is manufactured to be uber strong, even when it becomes super hot. The implication is that it could work in settings like factories or engines, where the temperature can become extremely high. Inconel 601 bar‘s toughness is due to its connecting several different metals to make it strong.

How Inconel 601 Bar Holds up Against Extreme Heat

When things heat up, most metals just start to melt or become damaged. But not Inconel 601 bar. This unique metal resists temperatures of up to 1250 degrees Celsius and won't break or bend. This makes it an ideal material to use in hot places, like in furnaces or power plants.

Revealing the Far Better Heat-Resistance of Inconel 601 Bar

It's all about the composition when it comes to the incredible heat resistance of Inconel 601 bar and alloy bars . It consists of a combination of nickel, chromium and iron all metals that can withstand high temperatures. And when these metals are mixed, they produce a substance that possesses both strength, but does not corrode under the intense heat.

Realising the Potential of Inconel 601 Bar at High Temperature Applications

Inconel 601 is known for resisting high-temperature applications, in practice most 6061+ 1 bar dennissmith711704 2019-12-17T10:16:15+00:00 Alloy 601 is a durable nickel-iron-Chromium alloy with good physical and mechanical properties. It is typically used within industries such as aerospace or automotive, where the temperature is very high. Inconel 601 bar is used as a material in order for applications to withstand high temperatures.

Unconquerable Heat Resistant Inconel 601 Bar Industry supportive Stainless Steel Alloy

Inconel 601 Bar Really Is An Amazing Material That Resists The World’s Most Severe Temperatures Its resistance to very high temperatures makes it an important component in many industries, enabling the manufacture of products that are durable enough to handle tough conditions. Far and away, Inconel 601 bar is in a class of its own thanks to its impressive heat resistance and strength.

Finally, Inconel 601 bar and Nickel alloy bars is a very durable material, that will last in the extreme heat. It is also heat resistant and can withstand high temperatures without damage which is why it is unavailable and prohibitive for many other hot temperature applications or products. Because of its excellent heat resistance, as well as high tensile and creep rupturing powers, Inconel 601 bar can withstand incredible temperatures and wear over time. So if you next time you come across something that can withstand extreme temperature, then it is Inconel 601 bar.

Want to make sure your ECG recording is clean and smear-proof? There's a new standard in ER specific ECG recording paper, and it's made by In-better! This premium paper is designed to help make certain that your ECG Medical Paper reads are clear, not to mention more legible and easier to interpret, especially in emergency situations.

State of the Art Technology for Clear, Smudge Proof ECG Tracings

In-better ER-specific ECG printing paper adopts latest technology to prevent fingerprint and make every heart beat clear. With this paper, you can trust that all your ECG readings will be clear and accurate.

Fast-Drying Paper Provides Immediate ECG Results in an Emergency

In emergency situations every second counts, so you need ECG paper that dries fast for instant results. In-better Quick-dry technology means your ECG paper readings are ready to be analyzed immediately, so you can make critical decisions for your patients sooner.

Reliability: With fast environments

When you're busy in the ER or everyday in healthcare, your ECG paper needs to be reliable to keep up with the pace. In-better's ER-qualified ECG recording paper provides reliable, clear, and distinct tracings you can trust - even in your harshest testing environment.

Farewell, Smudged ECG Readings Hello, Quick-Dry Technology

No more playing detective on blurry ECG readings. The quick-dry technology of in-ear® make sure your ECG trace is always sharp and however long you wear them. No more messy smudges on the paper and no more frustrating results!

Improve Patient Care with ER-Ready ECG Paper that is Wound for Speed

Using ER-specific ecg paper quick-dry technology from In-better, you can step up the level of care for your patients. With crisp, smear-free recordings, you can feel good about your treatment decisions for your patients.

Finally, In-better ER ECG paper with quick-dry technology is a game-changer for the healthcare professionals who need to have a dependable, reliable and fast ECG reading during an emergency patient care. This paper contains technology that resists smudging and makes sure images are clear. Change to in-better ECG paper and feel the difference.

Hi, you ever want to know how long does it take to charge an electric motorcycle? So, here we go into the charging abyss together.

Knowing how long it takes to charge electric motorbikes

When it comes to charging your Chonghong Electric City Motorcycle , it is good to know that the charge time may vary depending on a few other factors. But a number of factors including the size of the battery, the speed chargers are capable of charging the battery, and the current level of charge in your battery can affect how long it takes to charge an electric ride fully.

Factors Determining how fast electric motorcycles charge

The preventing crime and losing, one of the main factors that may influence how quickly your Chonghong electric motorcycle charges will be the charger. Certain chargers are built to charge faster than others are, so if you’re interested in juicing up your bike as quickly as possible you’ll want to utilize a high-speed charger.

The battery's size can also play a role in how fast your device charges. Of course, longer lasting (and larger capacity) batteries can require a longer time to fully charge, so plan your charging time accordingly.

Fast charging for electric motorcycle riders

Quick-charging your Chonghong Electric Scooter motorcycle If you just need to charge up your Chonghong electric motorcycle as fast as possible, here are a few quick-charging options for you. For example, a few electric motorcycles have fast-charging capabilities meaning you can extend your battery’s life for just a fraction of the time it would take with an ordinary charger.

Some charging stations also provide quick service that can have you on your way in no time. Plug in your electric motorcycle, make yourself a cup of hot cocoa, and in no time you’ll be back on your way.

Electric Motorcycle Models Race to the Bottom (Fastest Charging Times)

When you compare the charging time of the various models of Chonghong electric motorcycles, You must consider the battery size and the charger of charging speed. There are some models which could require longer charge-time as compared to the others, so make sure to do you research before making the switch.

For instance, a smaller Chonghong electric motorcycle with fast-charging may charge faster than a larger model with a regular charger. You’ll just need to be sure you can strike that ideal balance of battery size and charging speed for your use case.

How to get the most out of charging your electric motorcycle

Top tips to get the most from your Chonghong electric motorcycle When charging your electric motorcycle, you'll want to make sure it's using the best technology available to charge it as quickly and as efficiently as possible. One, try to use a fast charger as buildings up some charge quickly will definitely help if you don’t want to stay away from the public anyway.

Also, at least attempt to charge the Electric Motorcycle when there’s less juice left in the battery pack as opposed to when it’s fully drained. This can help shorten charging time and help protect your battery.

And for those instances when you have to charge on the fly finally, you could do worse than to bling yourself with a power bank. With the right tools and a bit of planning, however, you can ensure that your Chonghong electric motorcycle is always prepared for your next great ride.

So there you have it, all you ever wanted to know about charging your Chonghong electric motorcycle. With a little bit of knowledge of charging time, the use of some simple calculations, a few tips and quick charging options, you can ensure that your e-scooter is always ready to go at a moment’s notice. Happy riding!

Ice making machines are essential for concrete cooling. There are variety of ice machines suitable for such work. Icemedal Refrigeration Equipment provides several solutions for ice machine concrete cooling. Read on to learn about the advantages of an ice machine plus considerations when selecting one to help you ensure an efficient concrete cooling process.

The role of ice machines in concrete cooling explained

In order for concrete to maintain its strength and durability, it has to be cured at the right temperature. Ice machines for cooling down the concrete mix could assist with this. When ice is introduced into the mix, it brings down the temperature, slowing down the curing process and eliminating the threat of cracking. Commercial ice machines make the ice, which can be crushed and added to the concrete to help keep it cool in hot weather.

Evaluating various ice machine alternatives for a concrete cooling application

There are different ice machines for concrete cooling. Flake ice makers generate tiny, thin parts of ice which can be very easily included into the concrete batch. Plate ice machines output flat sheets of ice that are crushed prior to being mixed. Tube ice machines: produce cylindrical ice tubes that can also be crushed to use as ice pack to cool concrete.

Advantages of ice makers for cooling concrete

There are several advantages associated with using ice machine maker for cooling concrete. It aids in temperature control of the concrete mix, which is important for ideal curing. Ice machines are also a more reliable and energy-efficient means of cooling than traditional methods. They are able to make ice fast and in huge amounts and are perfect for your big construction projects. Further, employing the ice machine for concrete cooling, may also lead to minimizing cracks and improving the qualities of the final construction.

Key aspects for selecting a concrete cooling ice machine

Factors to Consider When Selecting a Concrete Cooling Ice Machine. Size and Capacity: Think first about the size and capacity for the ice machine. Ensure it is capable of producing enough ice to serve the cooling requirements of your project. And don’t forget the caliber of ice flow the machine churns out. it is often considered to apply the flake ice for the building cooling, what's because the flake ice has excellent performance of fast cooling with the largest contact area with the construction. Also, take into account the ice machine's energy usage and the ease of maintenance to maintain operational efficiency.

Understand top ice machine choice in application for effective concrete cooling operations

The Ice Products through the Icemedal Refrigeration Equipment including ice machine models can ensure efficient concretes cooling functions. Our flake ice machines are built to produce good quality ice which can be used to mix with the concrete. Energy efficient, low maintenance VISIBLE FIXTURES for construction projects. Another use for our plate ice machines is in concrete cooling, as the flat ice sheets we create are easy to crush to the right specifications. Whatever your specific cooling requirements, Icemedal Refrigeration Equipment can fill them with one of their fine ice makers.

In summary, commercial ice machines are key equipment used to cool concrete during works. Icemedal Refrigeration Equipment supplies different types of ice machines for effective concrete cooling. Through understanding what ice machines are, putting their many types up side-by-side, and details on specific features, you should be able to decide what one is right for you! Rely on Icemedal Refrigeration Equipment for your every concrete cooling need.

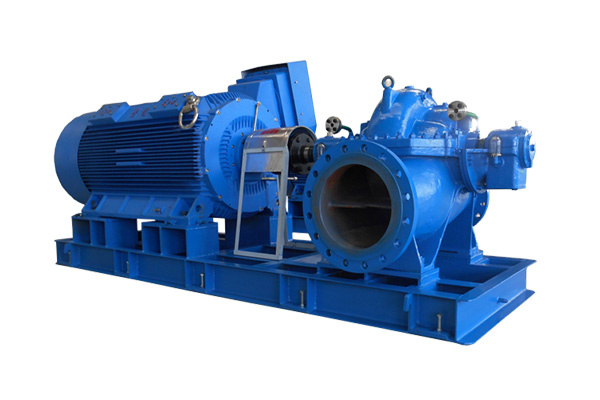

API 610 pumps and API 685 pumps may sound super big and super fancy to regular folk, but in reality, they are just types of pumps that are utilized and applied in different industries for purposes specific to that particular field. When considering which pump is right for your application, it is crucial to understand the differences between these two styles along with your system's requirements.

Knowing the distinctions between API 610 and API 685 pumps:

Api 610 pump serve industry around the world, including oil and gas, petrochemical and refineries, for offshore and onshore applications. They're versatile, dependable and have one of the most popular amplitudes for all-blade tasks.

Conversely, API 685 pumps are intended for use with dangerous or toxic fluids, which are common to industries like chemical processing and pharmaceuticals. These pumps are designed and manufactured to the highest safety measures to keep both the operators and our precious nature safe.

What to consider before choosing between API 610 vs API 685 pumps:

When deciding whether to use an API 610 BB2 horizontal split multistage pump or an API 685 pump, you need to take into account the demands of your application. Factors to take into account include the nature of the fluid being pumped, operating conditions, the degree of safety needed and the cost of the pump.

API 610 vs API 685 Both speed and size of pump will be a matter of co.

API 610 Pumps are even one of the best performance pumped valves and in other words, widely used across various industries. These pumps are suitable for a variety of fluids and operating conditions, making them ideal for many industries.

API 685 Types API 685 pumps, however, are dedicated to dangerous or hazardous fluids. Constructed to stringent safety standards for safe and reliable performance, these pumps support both workers and the environment- the kind of protection that makes them a good choice for applications that involve handling hazardous materials.

Why the correct choice of pump will make or break your application:

It is essential to select the best pumping system for your needs to prevent inefficient and unsafe operations. The incorrect pump will can cause expensive downtime, unsafe conditions, and further environmental issues.

Decision support in the selection of API 610 vs API 685 pumps:

When deciding between api 610 and API 685 pumps, be sure to take a close look at your specific requirements and consult a pump expert for guidance. By researching these 2 types of pumps and keeping a few things in mind, you can make sure that you are getting the right pump for you.

In summary It’s a big decision to choose approach between an API 610 pump and an API 685 pump but knowing the differences between these two types of pump and knowing the unique requirements of the application will make the decision-making easier and in that way you can ensure the efficiency and safety of your operations. And, as always, if you’re not sure what pump is best for your application, consult a pump expert to assist with your selection.