@shiela

- Followers 0

- Following 0

- Updates 804

What is the different stepper motor with closed loop stepper motor?

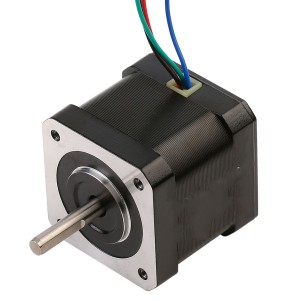

INDUSTRIAL APPLICATIONS: The stepper motor is widely used in many machines and equipment for controlling the movement. They make small, measured movements in order to be positioned exactly where they need to be. But, there is also a type of stepper motor known as a closed-loop stepper motor that provides even more exactitude and accuracy. Let’s take a look at how some of these differences stack up, and why industries are shifting from using regular stepper motors to close-loop stepper motors.

Stepper motors vs the closed-loop stepper motors

Stepper motors work by receiving electrical impulses to move in exact settings. There are no feedback mechanisms to tell whether the follower has reached the correct place or not. On the contrary, a closed-loop stepper motor has feedback sensors that inform the controller how it is doing by having an accurate way of getting to its position. This feedback loop provides more precise control and precision in a closed-loop stepper compared to an open-loop stepper.

What’s so good about closed-loop stepper motors anyway?

Limits to the number of steps can also be quite high in closed-loop stepper motors. One side-effect is that of increased accuracy. As it gets regular feedback on its status, a closed-loop stepper motor has the ability to change the way it moves in real-time so that it will reach that position exactly. This means that closed-loop stepper motors are suitable for tasks where accuracy is crucial, for example in robotics and automation.

Improved reliability is also another benefit of closed-loop stepper motors. Since they are able to sense errors and rectify it on spot, closed-loop stepper motors hardly ever lose steps or stall. This leads to increased and stable operation, minimizing chances of breakdowns and maintenance costs.

Why closed-loop stepper motors are the solution for achieving accuracy and precision

It is the tec It is the technology of closed-loop stepper motors that differentiates them from standard stepper motors. Closed-loop step motors have encoders or resolvers that continually feedback to the drive the position of the motor. This feedback is regularly sent to the motor controller, where it's compared with the target position and adjustments are made to exact movement.

By staying as in touch with itself as it possibly can, a closed-loop stepper motor is able to plan for the differing factors that may result from different loads or outside forces. With the power of real-time adaptability, closed-loop stepper motors can remain on their target position even under difficult circumstances.

Use of closed loop stepper motors in different industries

Closed-loop stepper motors are found in many industries where precise control is required. For instance, within the field of mobility (medical), closed loop stepper motors are utilized in robotic surgery systems to carry out complex operations with great precision. In the aerospace field, a closed-loop stepper motor can be applied to flight control system so as to assure the stability and safety of airplane.

In the industrial sector, these are used in CNC machines which cut and shape materials to produce a final product. Manufacturers can also get tight tolerances and uniform quality by using closed-loop stepper motors.

In general, closed-loop stepper motors have many advantages over conventional stepper motors in terms of precision, reliability and flexibility. Due to their advanced technology and accurate control, closed-loop stepper motors are more and more used in a plethora of industries that demand high precision and performance.