@lynrose

- Followers 0

- Following 0

- Updates 221

Controlling Shrinkage in Aluminum Gravity Casting: Techniques for Dimensional Stability

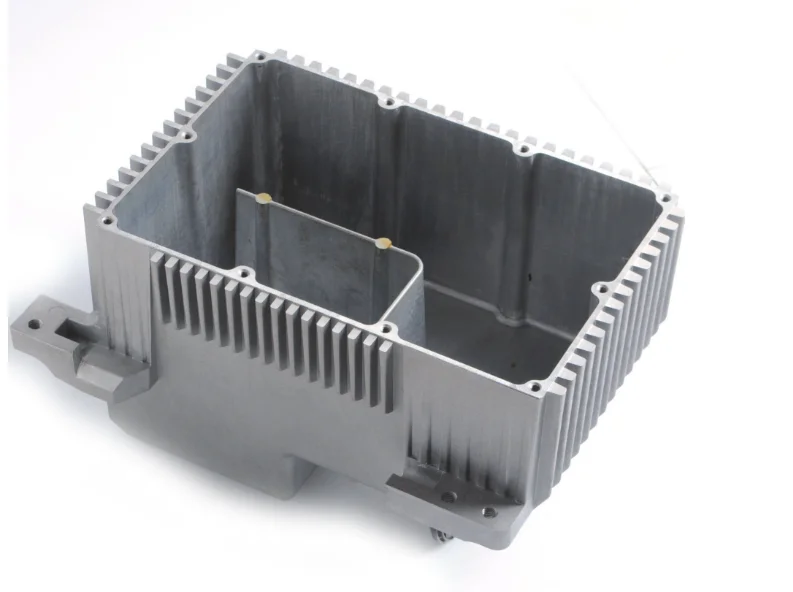

Aluminum is important as well because it is strong, light and formable. Gravity casting is the process by which we can shape aluminum one of those ways. Gravity Casting is where we pour molten aluminum into molds and let it cool and harden. One of the problems we face when gravity casting aluminum is shrinkage.

The Impact of Shrinkage on Aluminum Gravity Casting

As a note, some shrinkage occurs as the Aluminum Die Casting and hardens in the mold, making it slightly smaller than what we intended initially. This is a huge problem because it will alter the final measurements of your product and that thing might not, end up fitting right. Shrinkage can lead to additional defects like cracking or warping, which in turn may render the end-product too fragile for use.

Ideas To Reduce Shrinkage In The Aluminum Casting Process

There are few techniques available to reduce the shrinkage in Aluminum Gravity Casting g. One of those methods is controlling the temperatures of molten aluminum so that it molds and cools in the correct way. This can be done by planning the mould in part flow design so that there is ample space for gasses to escape and also decrease using gas release vents that gives passage for them from cavity section. These are the techniques that will help us to get, at our plants, the proper dimensions of our aluminum products and prevent their defects generated through the shrinkage.

Dimensional Stability in Aluminum Gravity Casting

It is necessary for the aluminum gravity casting to ensure that no distortion occurs when delivering; it should be stable in size, and have a minimum of dimensional stability. In order to achieve dimensional stability, the cooling and hardening of the aluminum must be carefully controlled. Ensuring that the aluminum cools down evenly and at the proper pace can help prevent shrinkage, as well as guarantee our products are correctly sized.

Solving Shrinkage Problems in Aluminum Castings

Conclusion Shrinkage is the biggest problem in Steel Investment Casting that create lots of challenges, but if we used the perfect techniques and strategies then all these challenges will be solved with a great ability. Shrinkage is a challenge were the mold must be properly designed for it. A further issue is detecting the temperature of melted aluminum so that it will no longer cool fully and hardens. Identifying and addressing these challenges will result in higher-quality aluminum products while keeping shrinkage defects out of the equation.

Quality And Efficiency By Shrinkage Control In Aluminum Gravity Casting

Through the use of our shrinkage control techniques we can enhance both part quality, and overall efficiency within all or aluminum gravity casting processes. Reducing shrinkage will help prevent defects and ensure our product dimensions are correct. This allows us to avoid re-work or scrap due to shrinkage related issues, cutting down on time and cost. In the end, with careful shrinkage control we are able to produce high quality aluminum products that provide us and our customers the reputation of Pengxin as a manufacturer you can depend on for new solutions.

In summary, aluminum gravity poured casting shrinkage is widespread; however, by understanding its influences and applying successful measures for controlling it, dimensional consistency may be achieved and our product quality and efficiency will rise. By facing the shrinkage puzzle and keeping our eyes on dimension control we do not only fulfill Pengxin´s requirements, but also deliver aluminum product of very high quality.