@lynrose

- Followers 0

- Following 0

- Updates 221

Medical Imaging Equipment: Cooling Demands Met by Custom Extrusions

Imaging equipment, such as X-ray machines and MRI scanners, are played the essential role in helping doctors get a look into the human body to diagnose and treat a variety of health problems. Nonetheless, when these machines are running they produce a lot of warmth that can influence their presentation and life expectancy. Custom cooling solutions are typically required to maintain optimum temperatures for proper operation.

Given the risk and logistics involved with medical imaging, it is crucial that all aspects of this field are properly understood including cooling. This requires tight temperature regulation to work correctly and deliver valid results. Remgar creates cooling solutions that fulfill specific medical device needs by utilizing custom extrusions.

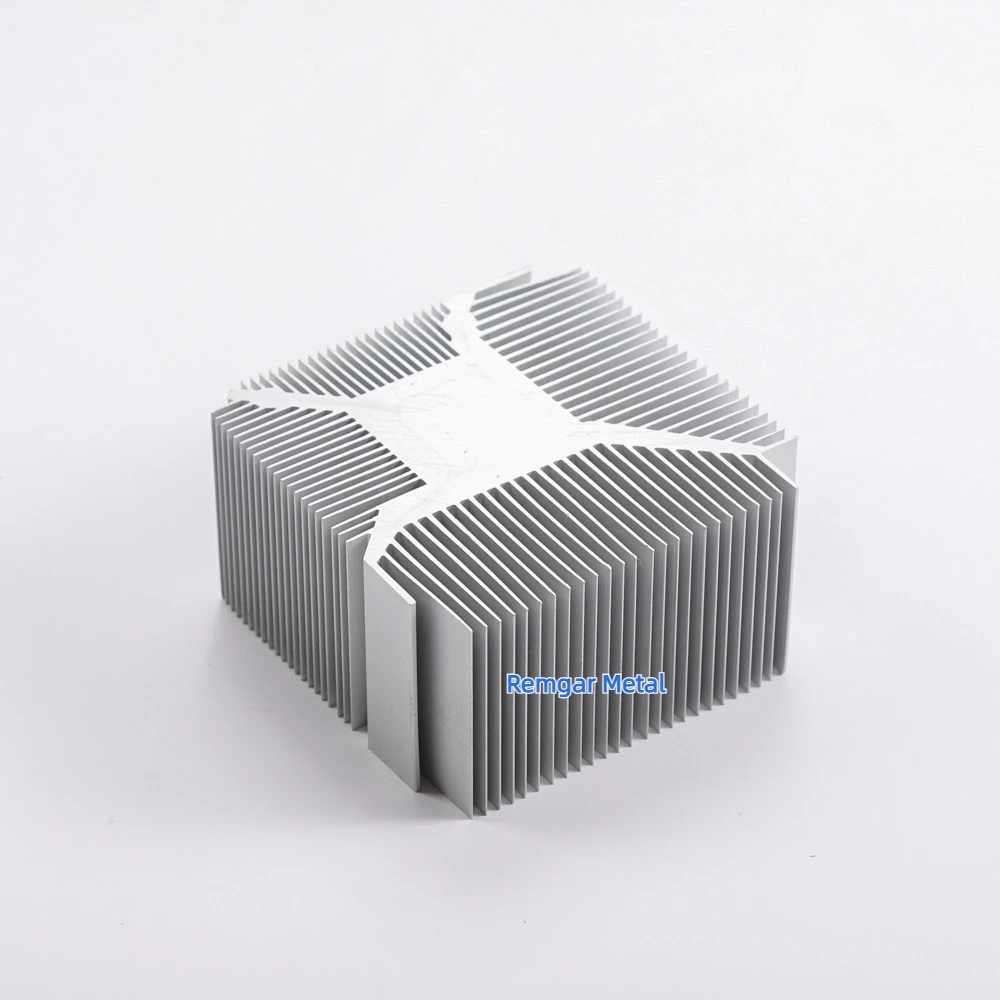

One such solution is custom extrusions, which provide an option for keeping medical devices at the ideal temperature. These are components developed to regulate temperature and allow heat dissipation of medical imaging equipment. If these extrusions are incorporated in the design of machines, manufacturers can be sure that these machines would work efficiently and effectively at all times.

The necessity of custom extrusions in heat sink manufacturer for medical imaging equipment is unquestionable. The combination of these components creates an answer to the cooling problems experienced by medical device makers. Remgar partners with such corporations to create tailor-made cooling solutions that helps them enhance performance and extend the lifespan of their medical equipment.

The performance and lifetime of medical imaging equipment can be optimized with aluminium heat sink manufacturers solutions. Custom extrusions provide a way for manufacturers to keep their devices running at the right temperature. It also makes the images that come out more accurate and it increases the life of your equipment too.

The transformation that custom extrusions are doing for the custom heatsink manufacturer used within the scanning world is profound. The cooling technology that was previously limited to ultra-high-performance applications is now available, putting the expertise of companies like Remgar to work for medical device manufacturers. Why: These custom extrusions are helping drive the next wave of medical imaging equipment design and construction, resulting in far more reliable (and cost-efficient) machines.

In conclusion, custom extrusions are an important part of the equation for cooling medical imaging equipment. Working alongside companies such as Remgar to design bespoke cooling systems, manufacturers can boost the performance and lifespan of their devices. New advancements in medical imaging coil manufacturingMedical Imaging Coil Providing New Cooling Capabilities for Patient CareThese extrusions are transforming the way that the medical imaging industry is able to provide cooling for equipment.