Blogs

Striking the right balance of quiet operation for bedrooms and nurseries.

When it’s time to create a calm, soothing atmosphere in your bedroom or nursery, you want to have a cool mist humidifier that imparts the right amount of mist, and ensures that your diffuser is easy to adjust, and is not making noise that will keep you and your baby awake. It’s often a delicate dance of staying quiet while still actually being effective at adding moisture to the air. At NURFIODUR, we know the value of selecting a model that does not wake you, or your baby up. We're going to see how you can choose the best humidifier diffuser for peace in your home.

Finding the best models that won’t wake up you or your baby.

Choosing the right humidifier diffuser to ensure that noise is dialed down as low as possible will also aid in creating an ambient, sleep environment for your bedroom or nursery. You're looking for a quiet model, one that will work all through the night ensuring you and your baby get plenty of rest. NURFIODUR NURFIODUR quiet humidifier diffuser is the ideal choice for achieving the desired humidity level in your house without compromising the peaceful and relaxing atmosphere in the room. When you select a model that's designed to be virtually silent, you'll create a calm environment that promotes deep REM sleep for everyone.

Selection of a humidifier diffuser to guarantee a peaceful sleep for the whole family.

When choosing a humidifier diffuser for a bedroom or a nursery, it’s essential to take noise level into account. Noisy and disruptive, a loud humidifier can prevent you from sleeping soundly, and make it difficult for your baby to sleep as well. NURFIODUR noise reduction humidifier diffusers have a very low noise, almost silent operation, which can make you relax and enjoy a extremely comfortable sleep. Opt for a model with quiet performance, so you can sleep sound while everyone in the house breathes easily.

Discovering The Newest In Noise Reduction For Peace & Quiet.

Latest technological breakthough produces the powerful cool mist ring and humidifier averaging a noisy 30 dB so quiet it won't interfere with your sleep or work. NURFIODUR's Humidifier&Aroma Diffuser new models have noise reduction properties that allow quiet use for bedrooms and baby rooms. When you see the newest noise-reducing technology, you'll want to grab a humidifier diffuser That not only adds moisture in air, but also create a quieter, comfy cozy environment in your home. With NURFIODUR smart systems, you can breathe in ideal humidity without any noise annoyances ever again.

Choose a silent humidifier diffuser that makes a relaxing environment in your baby room.

If you want to have a relaxing environment in your Aroma Diffuser baby room, then you will find a silent humidifier diffuser necessary. The soft whisper of a quiet machine can help your tiny human drift off without having to live in a dry, stale Humidifier environment. NURFIODUR has a line of silent humidifier diffusers just for nurseries so your baby can slumber soundly. When you select a model with quiet function, you can create a quiet environment for your baby to enjoy a good sleep. Features + Invest in a NURFIODUR humidifier diffuser, and take the guesswork out of creating an ideal sleep environment for your baby.

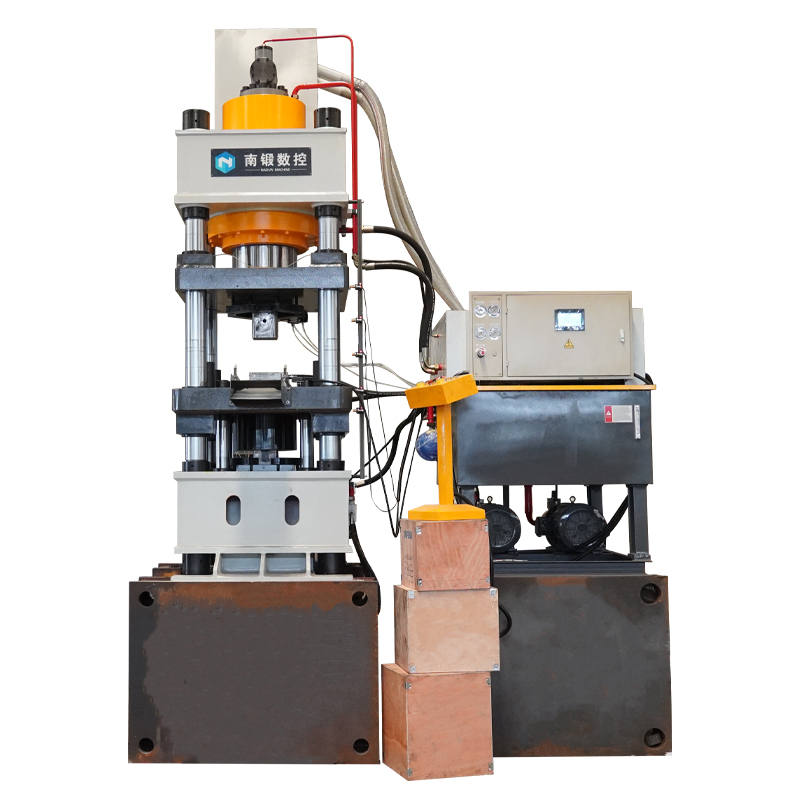

Knowing about the various types of salt brick making machines is vital if you are planning to purchase one for your business. So, given these options in the market, you need to know the core differences in order to make your decision. From manual-operation machines to full automation, each type has its own production requirements and performance levels. By learning differences, you‘re going to be able to select a salt brick making machine that will work good for what you need it for and that costs a good price.

Things to consider when buying a salt block machine

There are a few considerations when you need a salt block machine. First, decide to what volumes you want to produce. No matter what your scale of operation or output needs, selecting a suitable machine is a priority. And also, consider how much automation you want. Manual devices might allow more control, they’re also more work, and fully automated ones can simplify everything but are more expensive. It's important to examine the quality and life of the machine if it can meet the demands of salt bricks production.

Features and specifications of different types of salt brick making machines compared

It is crucial to compare the features and specifications of various salt block making machines so you can decide which one is right for you. Consider production capacity, forming pressure, power consumption and degree of automation. Some units have bonus features such as adjustments for brick sizes, or even more advanced safety innovations. These are all attributes you should examine closely, so that you get a machine that meets your production needs and also improves efficiency and safety in your operation.

How to get the best manufacturer of Salt Brick Making Machine?

It’s very important for you to find a good and reliable salt brick making machine manufacturer to guarantee the quality and the functionality of your investment. Choose the manufacturer that has experience in the industry and that has satisfied customers to prove it. Think about an item they are perhaps experienced in the production of salt brick making machine and dedication to quality plus customer satisfaction. Also ask about post-purchase support, warranty and spare parts to keep your machine running for years to come.

How to Make Informed Purchase Decisions on Salt Block Brick Making Machines

A salt brick making machine hydraulic brick press is a large purchase and one that should only be made wisely after exhaustive consideration and reasearch. Consider your production needs and budget, while also looking at the big picture to help you determine the most effective machine for you. Weigh up things like production capabilities, degree of automation, quality requirements, and the manufacturer's reputation and you're bound to make an educated choice. By hydraulic brick press machine doing so through the investment of your time to learn about the types of machines, compare what they offer and who makes them, comfort in making the choice of a salt brick making machine that will take production to a new level and ensure for a good life in the progression of your business.

In remission of salt bricks manufacturing process for feeding livestock

Nadun Salt Brick Making Machines do not require the operator to press, save time, easier and more convenient for feeding and feeding livestock.Curing method nadun curing in order to make livestock salt bricks with a prototype standard of uniform quality (no hollows, no wrinkles, no patron), technically easy to wash brick, good strength, salt thickness symmetrically, these two things will be equally messy for the brick, to keep the animals healthy and give birth to a well-grown healthy growp. With our modern equipment, farmers can now easily produce consistent salt bricks to supplement their animals nutrients in a more productive way! A system like Nadun helps to automate so much of this work which actually requires a great deal of hard work and time for farmers, and gives them back time to do other things.

Boost productivity in the production of industrial salt bricks

Not only useful to animal farmers, Nadun’s automatic salt brick press machines can also address the requirements of such end users as industrial units looking to manufacture salt bricks for a variety of commercial purposes. Our machines allow companies to increase productivity and resource utilization to fulfill demand of salt bricks in mining, construction, chemical processing, and many other industries. Providing powerful production efficiencies, Nadun enables industrial manufacturers to produce more, with greater reliability and efficiency.

Automated Salt Brick Press Accurate cutting down on manlabour costs in insightfulimenions.

There are many important benefits of using Nadun automatic salt block press machines which include lowering the cost of work for livestock farmers, as well as, for industrial manufacturers. Our machines automate the production of salt bricks, doing the job of human hands and making businesses more efficient. This is one if the features of the NADUN TECHNOLOGIES machines that saves our customers thousands of dollars a year in added production, and this makes NADUN Machines the right investment for any shop looking to maximize its production operation!.

Variety of option for salt brick sizes and shape for custom design

At Nadun) we know every customer is different and so the size and shape of your salt brick count. That’s why we have customizable options that will allow hydraulic brick press farmers and industrial producers to make their salt bricks however they wish. Whether you require big, rectangular shaped salt blocks for cattle or smaller, round salt bricks to be used in industrial environments, we can tailor our equipment to fulfill your precise requirements. This flexibility allows our customers to manufacture salt bricks that are tailored to meet feeding and manufacturing needs.

Solid and durable performance for consistent salt brick production

In salt brick production, it’s all about uniformity. Nadun hydraulic brick press machine offers automatic salt brick press machines that are long-lasting and dependable, ensuring consistent quality with every use. Our products are made using industry best standards and find extensive use in commercial areas and homes for uninterrupted work processes. With Nadun machinery customers are now guaranteed of reliable and efficient salt brick production to cater for their feeding and manufacturing requirements.

New Technology for the Salt Blocks Production

Efficiency and precision are critical in the industrial space. If you are involved in salt brick production, the right equipment can be the key to your success. This is where Nadun can help with the latest salt brick making machines available which have been developed and engineered to efficiently produce and maximize output. With cutting edge technology our industry leading service is sure to provide the tools you need to grow your business.

Reliable Manufacturers Offering High-Standard Salt Brick Making Machines

At Nadun we are commited to giving you the best. Our team of professionals that use our precision high-quality salt brick machine for long enjoying its work. We have decades of product expertise and know what our customers want, ensuring they receive the best results. What this mean?others can't compete!Our commitment to this policy is immediately obvious in everything we do. With Nadun, you can depend on a dependable, high quality product that will elevate your production.

Trusted Partners for Your Salt Brick Manufacturing Requirements

“Nadun” is your reliable partner for all your salt brick making services as a leading recipe for a successful industrial producer. Small or Large, New or Established Business, we have everything you need to Thrive. Our range of products are created to help save you time and allow your to work more efficiently, putting the customers needs and other tasks ahead of your paintwork. With Nadun by your side, you can be confident knowing you have the best equipment available to allow your business to flourish and continue to surpass your competition.

Exclusive Salt Brick Making Machine Supplier in the Industry

As one of salt brick making machine manufacturers, Nadun has been a brand. Our company is well reputed for it’s excellentqualityproducts, innovative technology and hydraulic brick press customer orientedapproach. We have become known for the quality of our products as well as exceeding the expectations of our customers. At Nadun, you can be assured that you are working with a company that cares about providing you with the highest level of quality service for all your salt brick making requirements.

Optimize Your Production Line with the Superior Salt Brick Making Machines

In our fast moving world, efficiency is everything. That’s why Nadun provides a variety of salt brick machines that are designed to optimize your production process and increase your yield. Our machines are built with hydraulic brick press machine cutting-edge technology so you can take the marketplace with ease. Whether you want to accelerate production, exercise greater quality control or minimize downtime, Nadun has your solution. Elevate your operation and reach new levels of success with our top of the line salt brick making machines.

Improving OEM Performance and Effectiveness with Bespoke Hydraulic Tire Presses

In the tire making business, for Original Equipment Manufacturers (OEMs), to survive in the scene of competition, the efficiency and productivity are the leading issues. OEM Customized Solutions Nadun has thorough knowledge about the special requirements of OEMs regarding hydraulic tire press solutions which improve productivity and tire quality. These products are configured to the specific needs of individual OEM, achieving easy integration with their production.

Custom Hydraulic Presses

Specialist hydraulic presses from Nadun machine tools have been developed to help tire OEMs do just that. Constructed for precision and engineered for reliability, these presses use global industry leaders high-end materials and state-of-the-art technology to place them among the top performing presses. For making, molding, vulcanizing and finishing tires - our hydraulic presses are capable of everything from bead to bead.

Satisfying OEM Tire Production Requirements with Bespoke Hydraulic Press Solutions

OE makers find themselves in the predicament of trying to meet quantity production with quality performance. Nadun's specialty hydraulic press systems are the solution to this problem, providing OEMs with a cost-effective solution to increasing production capability without sacrificing product quality. Because we tailor our hydraulic presses to the specific requirements that OEMs may have, we are able to streamline that OEM’s manufacturing process and enable them to achieve the best results possible.

OEM Hydraulic Tire Presses Customized for You

Having more than 10 years of market expertise, nadun's built-to purpose hydraulic tire press systems are developed with the needs of the OEM tire maker in mind. Our dedicated team of professionals collaborates closely with each OEM to help them gain a clear understanding of their production objectives, as well as the challenges they face so that we can create custom solutions that fit their unique requirements. Whether it’s fostering greater production rates, enhancing product quality or minimizing downtime, Hydraulico’s bespoke hydraulic tire press solutions are thoughtfully engineered to support OEMs in achieving their goals in a competitive industry.

Custom Hydraulic Press Solutions for OEM Tire Manufacturers to Power Innovation and Quality

Invention and excellent quality is the favorite slogan Solid tire press machine of Naluj hydraulic presses offered to OEM tire makers. Because we build the latest technology and industry best practices into all of our hydraulic presses, we work with OEMs to help them innovate and remain competitive in the tire industry. This means every hydraulic press that we manufacture is of the highest quality and is guaranteed to last, giving OEs a resilient and superior solution for their tire production requirements. Thanks to Nadun’s tailor-made hydraulic press solutions, tire manufacturers can innovate, become more productive, and increase their tire quality.

Factors to See Price of Bricks Making Machine:

There are multiple factors that contribute to the price difference of a salt brick making machine. Size and power is a major consideration. It could be that the larger machines will be more expensive, but will make more salt bricks at a time. Another issue is the materials the machine was made of. Machines constructed from durable materials may also cost more. Furthermore, the model of the machine may also influence the price. A few well-known-name companies may have a higher cost, but like all things in life, reputation and quality control can sometimes be worth it.

the cost of salt brick making machine:

In viewing the price for making salt bricks machines, there is a lot that goes into it. The acquisition cost is only one aspect of the total cost. Other expenses to consider are the maintenance and repair costs. Some machines are more heavily maintained than others and can therefore will be more expensive in the long run. Energy usage is a factor as some machines have better energy efficiency which will reduce the cost of running the system. Once you pop all of these costs, you can begin to see a better picture of the total investment necessary for a salt brick making machine.

Prices of Salt Brick Making Machine to Consider for Affordable Options:

It is good to compare prices of the salt brick making machine among various manufacturers. Though some machines might come with a higher price tag, they may actually save you cash down the road with low maintenance and energy costs. The budget of course, is the key to the equation as well, what may work initially may actually represent substantial savings over a period of time. Furthermore, searching for any promotions, discount, or package deals that are offered out there by the manufacturers can enable you to find a better price on one of these salt brick making machine. When looking at the prices and features of several machines, you may discover the best value for your application.

How to Find the Best Salt Brick Making Machines – Buying Guide:

If you want to get the best deal on salt brick making machines, there are a few things that you do well to remember. First, try not to purchase through middlemen who increase the costs of products. Fuck next manufacturer could give even better prices and discounts, particularly on large purchases. You can also read customer reviews and feedback on different machines to ensure you’re getting a solid buy for a decent price. Also, visiting industry trade hydraulic brick press shows or expos can often offer a chance to haggle over prices or find new affordable machines. With a little initiative and knowledge on your part, you can increase your chances of finding the best deals when shopping for salt brick making machines.

Select the Perfect Salt Bricks Making Machine at the Perfect Price:

While deciding on a salt brick making machine in your own budget, reflect on your precise needs and requires. Compare production capacity, size, and the other characteristics of various models and choose the suitable one based on your budget. Be sure to account for all potential costs, including upkeep, repairs, and energy, in your budget. It's important to hydraulic brick press machine find that happy medium between price and quality to make sure you’re getting a decent machine that won't break the bank. If you take your time and analyze your choices, and then you focus your attention on the most suitable salt brick making machine, you’ll make a great purchase that will pay off in the long run.

Air brake chambers are critical components to keeping vehicles safe and on the road. It’s important to maintain them so that they function correctly., and we'll discuss the reasons to maintain air brake chambers, the process of checking and maintaining them, how you can help extend the life of brake chambers, how to troubleshoot common issues, and how to ensure air brakes and the whole braking system remains safe and fully operational.

Knowing the Significance of Air Brake Chambers Having the Air Brake System in the vehicle is the best thing to consider.

Air brake chambers exert pressure on brakes to assist vehicles come to a safe stop. If the air brake chambers aren't maintained, they can break and lead to crashes. Air brake chambers need to be maintained properly regularly to ensure that they can work as they should and keep everyone safe on the road.

How To: Inspect and Maintain Air Brake Chambers Guide to Air Brake Chambers Inspection and Maintenance:

-

First, be sure to turn off the vehicle and keep it parked somewhere safe.

-

Check air brake chambers for leakage, cracks or damage.

-

Inspect the brake lining for wear.

-

Wipe Air-Brake Chambers Wipe the air brake chambers clean with a soft rag.

-

To fix anything you find wrong, spring for a pro mechanic.

Ways To Prolong the Working Service Life of an Air Brake Chamber:

-

Keep air brake chambers free from dirt and other contamination.

-

Monitor them often to detect any problems early.

-

Follow the manufacturer's maintenance schedule.

-

Don’t overbrake; heavy braking ousts air brake chambers a lot quicker.

Troubleshooting Air Brake Chambers: Common Problems And Remedies:

-

Leaks: Air seeping out of the chambers could indicate a crack or loose fit. Take it to a mechanic to have it inspected and repaired.

-

Bad Brakes: Your brakes should never lose effectiveness, which may signal the need for replacement of your brake lining. Replace it with new at your earliest opportunity.

-

Too Much Noise: Does your car make a loud squealing or grinding noise each time you apply the brake? It could be an indication that the brake lining is worn.

-

Overheating: When the air brake chambers become overly hot, it may be a sign that there is an issue with the braking system. Take it to an expert.

Reduce Risk and Improve Performance in Air Brake Systems:

-

Use all safety precautions when dealing with air brake chambers.

-

Stay on top of maintenance and inspections to detect problems early.

-

Ensure that repairs and replacements are made with parts and materials of the same grade of quality as those used in the original construction.

-

Educate train drivers and mechanics on the appropriate maintenance of air brake chambers.

In summary, maintaining air brake chambers is important in maintaining safety on the roads. By using the information below, you can make your air brake chambers last a very long time and work well. Always remember to take safety and routine maintenance first, so that you prevent accidents and make sure everyone in the road stays safe.

Brake pad are vital parts in your JINQUANFLEET car for safety. They are instrumental in your car being able to come to a stop when you step on the brake pedal. With bad brake pads, your vehicle wouldn’t stop as quickly and it wouldn’t stop as safely, increasing your risk of getting into a car wreck.

The centrality of brake pads to car safety:

Brake pads produce friction against the brake rotors, slowing the wheels and ultimately your car. This is one of the most important steps to ensuring your safety and the safety of others on the road. A vehicle that doesn’t have good brake pads may not stop in time, or it may not stop at all, increasing the chance of accidents.

Some signs that you need to replace your brake pads:

There are a few tell-tale signs that it’s time to change your brake pads. One of the most common is a screech or grinding noise that you hear when you hit the brakes. This rather indicates that the brake pads are thin with worn out and they have to be replaced. Lack of stopping power is another sign, you can tell if it suddenly feels like your car takes longer to come to a stop. If you notice any of these symptoms, you should have your brake pads checked and replaced if needed.

Various brake pads and their advantages:

There are various types of brake pads that are currently on sale in the market with their respective advantages and disadvantages. Organic brake pads are produced using materials such as glass, rubber, and kevlar, to create a smooth and low noise braking effect frogleg. Semi-Metallic Breaking Pads Semi-metallic breaking pads are comprised of metal fibers in combination with other elements, creating a sturdier and longer lasting heat and wear-resistant. Ceramic disc brakes are made of ceramic fibers (and other ingredients, including chopped glass) to improve comfort without sacrificing performance. There are advantages to both types of brake pad so make sure to pick the right one for your vehicle.

Proper way of maintaining and taking care of your brake pads :

Like everything on your motorcycle, if you don't properly maintain and care for your brake pads, they won't last as long and they won't work as well. It is critical that a skilled mechanic inspects your brake pads routinely for wear and tear. Maintaining your brake pads clean and debris free can also help keep them effective. Also try to avoid heavy braking and really hard stops, the wearing on your pads is far more accelerated. When you pay attention to your brake pads, you can help to maintain them so that your car stops when you need it to.

Frequently asked questions about brake pads answered:

- How long do brake pads usually last?

Do you ever wonder how long brake pads last? Brakes have a lifespan that ranges from 30,000 to 70,000 miles, depending on what you drive and how you drive and whether or not you have performance brake pads.

- Can I change brake pads myself?

Although some car enthusiasts might be able to change brake pads themselves, visit a mechanic to have the job is done properly.

- Do I have to replace all four brake pads at the same time?

It is advisable to change all four brake pads at the same time, so as to achieve even braking on all four wheels.

In Summary, The brake pads are very important to your JINQUANFLEET vehicle’s safety. By knowing the significance of brake pads, knowing when it is time to replace them, selecting the perfect type of brake pads, caring for and maintaining the brake pads, and dealing with related queries, you can make certain that your car stops safely and successfully when you need it to. “Always take care of yourself and others on the road by maintaining your brake pads,” she adds.

Are you up for an explosive and good time? Have fun while taking your work with you wherever you go with Hotop's incredible backpack made for remote work and limitless adventure. We are going to learn all about the amazing features of this awesome backpack!

The best for digital nomads and remote workers:

Whether you are a digital nomad exploring the world or a remote worker in need of a change of pace, Hotop’s backpack is the companion you need to have with you on all your adventures. Sturdily constructed and having comfortable straps, you can carry along your laptop, tablet and other office supplies effortlessly. No More Big Bulky Bags Whether you are going out for a stroll or prefer to move freely and light!

Made for both work and play:

Who said you can’t have fun and do business at the same time? Hotop’s space-saving backpack allows you to tackle work, then play, without cumbersome bags. This backpack has various pockets and compartments so you can organize all work and personal belongings. So, whether you’re out in the field or wandering around a new city, you’re covered with this backpack.

Get it here and never be disorganized and unproductive again:

You'll never have to worry about being disorganized when you're on the go with Hotop's genius backpack . No more digging through your bag to find what you’re looking for – this backpack has a place for everything, with pockets and compartments for your laptop, tablet, phone, and other necessities. With your things in their place, you can keep your head down and work out without hassle, wherever your travels take you.

Get out and explore while heading to school and store your gear in a bag that is perfect for an adventurous lifestyle- Pack and go:

Adventure ready with Hotop's backpack that is built to travel with you. Whether it's out in the mountains, taking a stroll to your local coffee shop or a new city, this backpack is ready. Constructed of durable, water-resistant material with a robust design for even those rainy days. So then, go on, be adventurous – Hotop has your back!

Get the perfect mesh of functionality and fashion with this remote work must-have:

You can now feel the perfect combination of function and fashion with Hotop backpack. From the neat design to the practical inclusions, this is essential kit for the remote worker or digital nomad. Beauty And Utility Hotop have made a backpack to meet your needs aesthetically and utility-wise. Then why not go the extra mile with Hotop’s remote work essential.

Final Verdict: Hotop’s Backpack Perfect for Working Remotely and Exploring Eternally Hotop’s remote work and infinite exploration designed backpack is a must-have for digital nomads or working remotely on the go. By its unique design, you can enjoy you're working and playing while on the road with this backpack. So why wait? Order your Hotop backpack now and take it on your next journey with you!

The preparation of good quality PET (Polyethylene Terephthalate) sheets can be a difficult process. But guess what? But with parallel twin-screw technology from JWELL Machinery, it’s not as difficult as it seems! Think of this technology as a kind of super-powered blender that mixes things perfectly to form smooth, clear and strong plastic sheets. Think of making a humongous pancake, except instead of using a frying pan, you have a special machine that molds it perfectly. That is the conception of how our jwell PET sheet extrusion line makes it, but it is plastic as opposed to pancake batter. Amazing the way technology can take raw resources and turn them into something useful like packaging or containers.

GETTING THE MOST FROM PARALLEL TWIN-SCREW TECHNOLOGY

When it comes to producing copious amounts of PET sheet in a short amount of time, the parallel twin-screw is the best friend one could ever hope to have. This technology enables our machines to operate super fast and make a lot more sheets than older machines. You’ve heard those rare folks who are excellent at multitasking? And so consider these screws the ultimate multitaskers. They can mix, heat and shape in one fell swoop. So if you have hundreds, or even thousands, of sheets to make in no time, this technology has your back. It seems to me that, based on what I have seen, the efficiency is unequaled. It’s nearly magical to watch it zip right through the cycle from raw materials to finished sheets, not breaking a sweat. Believe me, it’s every bit as cool as it sounds.

High performance in extruding PET sheet with the latest parallel double screw system (SD-75H)

Quality matters. A lot. No one is looking for a weak or hazy PET sheet. State of the art parallel twin screw technology is used to ensure every sheet coming out of Jwell's line is the best in the world. This technology ensures the ingredients are mixed so thoroughly that the sheets come out crystal clear and very strong. It’s like making a perfect smoothie, where all the ingredients blend seamlessly. There’s an art to it, and this machine has it down pat. I watch the sheeting come out, and you can feel the difference it’s soft, strong and just beautiful. It’s the equivalent of staring at a masterpiece in the making, except with sheets of plastic.

Expanding production with a high output parallel twin-screw extrusion line

Now, let’s discuss how to ramp up production. Machine speed If you’re a factory owner or somebody who has to produce a lot of PET sheet making machine factory , you’ll need a machine that can keep up with the demand. Enter our high output parallel twin-screw extrusion line. This is not just a machine for accelerating production; it is a machine for supercharging it. Picture a race car on the track, speeding ahead of all the other cars. That’s how our production line works - making sure you have less waiting with more sheets. It’s like having a stealth weapon for your line, ready to tackle any obstacles in your way.

Keep ahead in the world with our PET sheet extrusion line.Undefeated

In the manufacturing industry it is so important to be ahead of your competition. Outpace the pack with JWELL Machinery’s advanced machineries for your PET sheet extrusion line. This is the best machine packed to the max with the latest technology to give you the upper hand at all times. Others may following onto you, but with our ahead tech, you will always be ahead. You can picture it as being in a race, being in the car with the fastest engine is hard for others to pass. That’s the sort of edge you gain with our equipment.

Improving efficiency and quality with a high output parallel twin-screw extrusion arrangement

Efficiency and quality both count. You can’t have one without the other if you wish to succeed in producing PET sheet food packaging extrusion . With JWELL's efficient parallel twin-screw extrusion system,you will have both! The system is a kind of finely tuned instrument, a melody of speed and precision. Since, it knows how to make the best sheets without wasting time or resources. For me to see how well it works is like going to a play with great lines and actors, and everything just goes along smoothly. And it’s not just about making more, it’s about making better and that’s exactly what this system achieves.