Blogs

Self-priming pumps are a great invention; they’re pump worker that pull water from one place to the other, such as pooling water into an irrigation system. These pumps are unique because they can get water flowing by themselves and do not require someone to dump water into them beforehand. Kaiyuan Pump manufactures these pumps so that people can work these in various manners.

The fundamentals of Self Priming Centrifugal Pumps:

Self priming centrifugal pumps are like magic! They can really draw water in and begin pumping it on their own.” That’s because they each have a type of chamber in the interior that makes it easier to suck and draw water in. A pump can keep moving water all on its own once it has been started.

The benefits of a self-priming centrifugal pump:

The efficiency and convenience of the self-priming centrifugal pump is its biggest benefit. Ludlow Instead of manually pouring water into the pump and waiting for it to start, you simply flip on the switch and let it do its thing. They are also very reliable and easily work in a variety of scenarios so that makes them versatile.

How self-priming centrifugal pumps work:

How do self priming centrifugal pumps work?These use a special chamber: A pr mi ngchamber. This chamber generates suction that draws water into the pump and gets it moving. Once the pump is primed, it can be left to circulate water by itself. This definitely makes these pumps very user friendly.

The self-priming centrifugal pump is widely used:

Applicataion Self-priming centrifugal pumps are used in a variety of applications. They’re commonly used to extract water from wells, drain flooded areas and move water from one place to another. The pumps are also employed in irrigation systems, firefighting and even some factories and buildings. They’re great because they can launch on their own.

How To Choose The Best Self-Priming Centrifugal Pump For You:

And when selecting a self-priming centrifugal pump, you have to decide how much water is available and how far it has to go. Consider, also, the qualities of the water you’ll be pumping as well as how much and often you’ll need to use your pump? Kaiyuan Pump provides several different types of self-priming centrifugal pump, so you can select the best one for your situation.

Finally, self-priming centrifugal pumps are an extraordinary invention which can add ease and convenience to the process of moving water. They function by generating suction with a unique chamber and can begin to pump water of their own accord. There are many advantages to portable recycling pumps, such as time and effort saving, reliability, and compatibility with wide range. They are utilized for everything from dewatering flooded areas to pumping water for irrigation. When selecting your self priming centrifugal pump think about the end-application and user's requirements. Kaiyuan Pump is your one-stop source for a self-priming centrifugal pump that will get the job done fast and effectively.

You Can’t Spot This Defect with Your Eyes — But Our Portable Micro-Indentation Tester Can

By shiela, 2025-10-15

Uncovering flaws in the hidden structure of matter URLWithString(true);}Accuracy and precision Determining whether there is a flaw present, and its location, shape, size and orientationahrenheit.

Did you ever think how companies ensure the materials they are using are of top notch quality? It’s not always possible to detect flaws using only the human eye. Enter our micro-indentation tester on-the-go!

Uncovering imperfections beyond the surface

At other times, the defects are not at all visible. They are invisible to the naked eye, and yet they can make big trouble. That’s why you need a tool to accurately measure these vulnerabilities.

Handy apparatus for light faultyÀUSES detection

Our Portable Mic HVIT is an incredible tool that will allow you to find minute faults in materials! It operates by creating small imprints in the material and measuring how well it withholds the pressure. This was because we are then able to identify mistakes that would pass us by unnoticed.

The power of micro-indentation testing

Micro indentation testing is an advanced process by which we can determine the quality of a material to a high level. Using our portable tester, we will guarantee the strength of applied materials that are empty from defects.

Ensuring quality through advanced technology

At Zhanghua, we take up-to-date technology to guarantee the quality of all material. Our portable microindentation tester is just one example of how we’re constantly working to make our processes better and our products even more useful for our customers.

In summary, with our portable micro-indenter we penetrate the might of matters - we programme hidden defects into materials and recognise faults above surfaces - confirming quality by modern technology. This new equipment means that manufacturers can be confident their products will always be strong and durable. You deserve to be confident knowing Zhanghua will service your projects the right way… all day, every day.

For companies like Zhanghua, upgrading to a skid mounted system can mean the difference. These systems are the big puzzle piece that makes everything snap into place just right. Now, lets look at the wonders of skid mounted packages!

How a skid mounted can boost productivity and cutdown on operational inefficiency.

So many of our customers, including a company like Zhanghua really gets their operations to the next level by investing in a skid mounted system! It just makes everything easier and smoother. Think about the difference between building a sand castle with your hands versus using a shovel and pail. The skid mounted model can be compared to the shovel and bucket—the job is faster and easier. That is to say, the products will be able to produced in short period of time which helps Zhanghua become efficient and successful.

The unspoken advantages of investing in a skid mounted process to turn short term profits into lasting ones.

While it might seem like a big investment at the outset, upgrading to a skid mounted system is akin to planting seeds that will in due time grow into abundant yield. These systems can end up saving Zhanghua a great deal of money in the long term. By becoming more efficient, reducing waste, the company can lower its costs and boost profit. It’s as if you have a magic money tree that just sprouts and sprouts!

Discover the little-known benefits of better safety measures with a skid mount system.

Zhanghua’s top priority has always been safety. By making the switch to a skid mounted system, not only is the company saving on time and costs but more importantly they are keeping all employees safer at work. These systems include safety features that can reduce the likelihood of accidents and injuries. You kind of have a guardian angel watching over the workers, so you know they are nice and safe. Taking safety seriouslyIn a sense, with their new guard marked “n°1” on it, Zhanghua is saying that they care about the health of their employees.

Why skid mounting can help you be more eco friendly.

Zhanghua is green at heart - we care for the environment and are responsible for our earth. By switching to a skid system, the business makes quite an advancement toward a more sustainable work environment. They are all energy-efficient and waste-reducing systems. It is like having a magic wand helping to minimize the company’s carbon footprint and making the world a cleaner, greener place for you and everyone else.

The advantages of switching to a skid mounted system for higher production and less downtime.

When all goes right at Zhanghua, it’s music to the ears. By going up to a skid mounted package you can be sure that every little thing is functioning perfectly, smoothly and like clockwork. They’re also engineered to provide exceptional performance and reliability – reducing downtime and increasing uptime. It’s like having a superhero standing by to swoop in and rescue you whenever there’s a problem. Zhanghua is in good company and will have a significant advantage over the rest of its competition by investing in a fully skid mounted system.

In the end, switching to skid-mount is a box full of jewels for Zhanghua . These systems deliver many advantages from increased worker productivity and money savings to improved safety and environmental protection. Zhanghua is future-proofing for a better tomorrow by converting to skid mounted. Well then, roll up your sleeves and say yes to a better future with skid mounted plants!

Crystallizers are indispensable equipment in various industries which enable the production of pure solids from solutions. But maybe, sometimes, your crystallizer isn’t has not got the looks you’re looking for from it., we’ll delve into some of these mistakes in operating a crystallizer and factors that affect how pure or clean the resulting crystal product might be and offer troubleshooting advice for how to produce cleaner crystals on your crystallizers without sacrificing greater production capacity (i.e. higher purity) – all laced with the chemistry behind cleanliness (purity). When you know these things, your Zhanghua crystallizer will provide the best results at all times.

Common Mistakes in Crystallizer Operation

A frequent mistake in the operation of a crystallizer is to fail cleaning and taking care of the equipment correctly. However, in time deposits can accumulate on the walls of crystallizer and decrease purity of crystal produced. Routine maintenance - Keep your instrument clean and check condition often!

Another common error is that people are not following recommended operating procedures. The Zhanghua crystallizers are each optimized to behave in a certain manner for the best output. You will be risking the loss of your crystals purity by not using them.

Factors Affecting Crystallizer Purity

The purity of the crystals obtained by a crystallizer can be influenced by a number of factors. One is the temperature of formation of the crystals. When the temperature is not acceptable (too high or too low) impurities that contaminate the crystals may be precipitated and purity can degrade.

The speed of crystal growth can also affect purity. Impurities can get stuck within the crystals if they’re allowed to grow too fast. Adjusting the rate of growth, by contrast, allows you to enhance your crystals' purity.

Other variables such as the solution concentration, the rate of stirring and the size of the crystals could influence purity. By continuously adjusting and supervising these parameters, you can rest in the knowledge that your Zhanghua crystallizer is manufacturing purest quality of crystals.

How can you fix your Crystallizer to get better purity?

If you're having purity problems with your crystallizer, there are a few trouble shooting techniques you can try to resolve the problem. The solution temperature is then measured and adjusted to the desired value. Keep the crystals at just the right temperature and avoid impurities by not having them grow within your crystals.

Now take a look at the crystalliser stirrer speed. Insufficient agitation of the crystals causes the impurities to be unevenly distributed resulting in lower purity grades. Purity can be increased by changing the stirring speed.

You'll also want to run the solution in the crystallizer whose concentration you are mining. If it's too strong adjusting the solution, impurities might have more chances to form inside crystals. You can also change your purity by watering down the solution, or by concentration.

Improving Crystallizer Efficiency for Higher Purity

If you want to obtain higher purity in your crystals, we give you some recommendations to improve the performance of your Zhanghua crystallizer. One possibility is to improve conditions for the crystal growth. And if you carefully select the temperature, stirring rate and other variables, you can favor the growth of pure crystals.

Another thing that you can do to help performance is to also use good materials when designing your crystallizer. In using corrosion and contamination resistant materials, you avoid introduction of impurities into the crystals.

You might also want to think about using a filter in your crystallizer. By removing impurities before crystals form, you can actually increase the overall purity of the final product.

The Chemistry of Crystallizer Purity Fouling explained

The purity of the crystals that a crystallizer generates is intimately related to process chemistry. Impurities may be added at any step in crystal growth to reduce the purity of the product.

A typical method for the introduction of impurities is forming solid solutions. In a solid solution, the solid solute absorps to occur the purity of crystal. Alloying In solid solution formation, know the conditions that lead to it so you can control it; ie, stop impurities from getting in.

Impurities can also affect purity through adsorption. Impurities can be stuck on a crystal surface which make less pure crystals. You can decrease the adsorption of impurities and improve purity by regulating the surface chemistry of the crystals.

To sum it up You develop your crystallizer in zhanghua but not get the purity you expected with helping of a few make array author In order to have that high grade(and garnet) crystallin within daydream beginners needtotrick upon aspects about your product and conditions which affect this purity. Preventing mistakes, troubleshooting sources of impurity, improving performance and knowing the chemistry of impurity issues will help keep your crystallizer in top form. With these hints you will never have to worry about maintaining a Zhanghua crystallizer of the purest grade of crystals.

This is the Agitated Nutsche Filter Dryer from Zhanghua , and although it may sound like a badger with a sexual dysfunction, this item has been ruffling quite a few feathers within process circles. But just what is an ANFD, and how does it pull off this feat of doing the work of three different vessels in a single vessel. Here we examine this piece of unique equipment and consider the value it offers operations.

How the Agitated Nutsche Filter Dryer is changing process industry

The ANFD or Agitated Nutsche Filter Dryer is a multipurpose product with fltering, drying & cake washing capabilities. This effectively means that where previously three pieces of equipment were required to do this work, one machine can now be used (ANFD). This eliminates a significant amount of space taken in the production sections and all the subsequently created steps, thus rendering it more efficient which leads to economical gain.

A complete description of the multi-task capabilities of the ANFD

ANFD contains: a filter plate for solid-liquid separation, a jacketed vessel to dry the filtered material and an agitator to mix and react. That allows operators to perform multiple tasks in one vessel, which simplifies operations and lowers the possibility of contamination. And it’s easy to clean also maintain, meaning you can keep your ANFD as radiant as possible.

Can one box do the work of three?

Yes, it is possible! The ANFD is an epitome of innovation and engineering. Zhanghua, has revolutionised the process industry by integrating a filter, dryer and reactor in one piece of equipment. The ANFD th tThis saves processing time and space simplifying the process, while improving operator ease of use and efficiencyios Although an additional initial investment is needed for the ANFD.

ANFD in your operations..Its cost saving and efficient implications

(EQ) How can a company benefit by investing in an ANFD? They save money on equipment cost, maintenance & repairs, and end-user power consumption – leading to increased efficiency overall. The multifunctional capabilities of the ANFD allow operators to perform more tasks in a shorter time frame, which translates into higher productivity and yield. Moreover, since the design of the ANFD is more compact it will occupy less room in a plant production space; additional room that could be used for equipment and/or processing.

Looking behind the scenes of the development of the Agitated Nutsches Filter Dryer

The ANFD is a device that integrates filter, dryer and reactor in one using latest state of art technology. Its filter plate is designed on basis of fully sealed filtration, so that the external contamination will not come into being. The business end of the machine can be arranged for correspond sliding Moulds or flat type plates.7070707Features: Our Model PPJ Series Filter Press has Good quality and only minimal water content in cake 1)Thickening by gravity You have to try this thickener outfitting effect 2)Electrolyte separation with high-quality stainless steel discharges compartment High frequency vibrations push products quickly through the media giving greater production capacities in shorter times6596465Equipment Introduction Our models including JPP20, 40,63,100,160 automatic poohed jack filtering press series products are made from filtering press by jacking device2817172Main technical parameter Type No. The agitator driven by the advanced motor, is a mixing and reacting device which is indispensable for many kinds of processes. All of these features combine to make a flexible and robust machine that is changing the process industry!

Finally, the ANFD by Zhanhua is a revolutionary instrument that has disrupted process technology in the chemical industry. The ANFD which is replacing three types of equipment with one compact, easily operable scraper crystallizer and cogged discharge knife assembly now not only saves time, money and space but also helps boost productivity. It’s designed well, and the technology behind it is second to none, which make this a fantastic choice for any business trying to cut costs and ensure that they come out as winners where the competition is concerned.

Nonwoven Machinery Upgrades for Higher Output https://www.nonwovensolution.com/Ss-spunbond-fabric-production-line783/superior-quality-fabric-machinery-nonwoven-production-line

By shiela, 2025-10-15

Non-woven fabric machinery is the key non-woven fabric production line to produce the high quality nonwoven fabrics. With the development of science and technology,Zhejiang Yanpeng has upgraded its notching machines and plastic recycling machine|tech for many times to adapt to the demand of things.

Improving Nonwoven Machines for More Productivity

There are many possibilities to improve the efficiency of nonwoven lines by reequipment with the newest machines. With better and new machinery in place, waste can be minimized and production times shortened so overall productivity is enhanced. Anhui Zhejiang Yanpeng also provides yield hassles for your nonwoven machinery features, such as the modern control process or even more simple surgical procedures that can be used to help make producing far more effective.

Making The Most Of Your Investment By Enhancing NonWovens Manufacturing Facilities For Greater Productivity

Higher production capacity can also be achieved when upgrading nonwoven machinery. With faster and higher-capacity equipment, companies can make more fabric in less time. This serves not only customer needs, but also profitability. Applications Zhejiang yanpeng machinery can specially offer 1-303T all kinds of models for refined white sugar Raw material: Sugar cane, sugar beet and in glucose plants Sugar cane do not need grinding, which is easy to cause the degradation of the saccharumOriginal Technology The semi-grainy or full-grainy homemade He card kind laced cassembly piece wetware connection type technology progress under conditional economic law? Article anxes are wizard's lock articles among them(5200 up) Category We pack with wooden case,it also accroding to customer requirement can very well protected.

Upgrade Nonwoven Fabric Better Quality Upgrades You Will Have

Besides efficiency and productivity improvements, new nonwoven machinery can also result in better quality fabric. Through investing in new technology and machinery, organisations can be confident that their products are of the highest quality and exceed customer requirements. Zhejiang Yanpeng provides forte upgrades which mainly targeting on the quality of fabric, such as:High-end PLC control systems and high precision components for better consistency.

Building Up Machines to Keep Pace With Expanding Industry

With expanding market and business demands, a great deal more nonwovens production capacity is urgently wanted and needed to be built on global basis. Updating Nonwoven Machinery to Stay Competitive and Satisfy Customer Demand_. Through the integration of technology and innovation, the companies such as Zhejiang Yanpeng are able to stay up to date with the latest trends in the sector and fabricate good quality cloth at affordable prices.

Upgrading to Get a More Efficient, Higher Yield and Profit-making Plant

Ultimately, the investment in nonwoven equipment can pay dividends through higher production and profit. And companies can use the power of AC drives to enhance efficiency, production and quality, so that they get a bigger bang for their production buck. Hangzhou Non woven Technology Co., Ltd Zhejiang Yanpeng Nonwoven Machinery Manufacturing Co.., which is the company awarded the large and medium-sized non-woven production lines famous brand of China.

Finally, the transformation and upgrading of non-woven machinery is very important for companies like Zhejiang Yanpeng to optimize its industrial structure, improve competitiveness and better meet market needs. Increased operational efficiency, productivity, quality and output lead to better performance and profitability for companies. Purchasing upgrades is a wise move for those companies that want to keep abreast of what the nonwoven market demands and ceaselessly deliver excellent fabric to their customers.

Benefits of silicon carbide (SiC) bushings and seals

Shandong Huamei New Material Technology Co., Ltd is a high tech enterprise that focuses on silicon carbide ceramics research and development,production and sales.Silicon carbide sealing bushings and bearings are used as seal faces with resin, metal, cast iron an Price: depending on the elements to be sealed AppleWebKit/537.36 (KHTML, like Gecko) Chrome/58.0. influx_v666eeee completean Seal surface should be free from contamination Read Moreuctile materials when wear resistant and anti corrosion performances are important 8 some acidic mediums require O ring mounted seals or T-seals Eal Shandong Huamei New Material Technolgy CoLtd edit MicrosoftInternetExplorer405@font?Ro materiaL Temperature Speed Allowable pv value galvanic action.andedge wim belt.lt Jere wtihai-beltSpecificationKm1282002 erumne el.ayedgelrnt.conv SiC is one of the most remarkable high performance ceramic materials due to its resistance to corrosion and wear, It has been widely used for applications requiring resistant seal in excessive temperature. Placing an emphasis on not only quality but also innovation, Huamei has been striving to develop SiC bearings and Seals as the new maintenance-free sealing solution that exceeds conventional seal choices.![]()

Improved ability of the seal to withstand heat levels of epic proportions

Heat is also a challenge among seals and bushings, as traditional materials can deteriorate or lose effectiveness when exposed to high temperatures. Huamei’s SiC bushings and seals can reach higher temperatures than other materials and deliver long-lasting service, even in the hottest industrial settings. Due to our meticulous processing and quality-oriented regimen, Huamei SiC products have superb thermal stability capability, enabling a continuous seal-ability and function over severe heat conditions. For industries such as aerospace, automotive and power generation ensuring a consistent sealing performance is a maximum priority element to safe and effective operations.

It is the answer for high-temperature applications

Huamei's SiC Shafts and Seals: Providing Solution for High volumes & high temperature applications in Industries. Having a complete chain of silicon carbide industry and rich experience in precision processing, Huamei independently manufactures SiC products that are suitable for each customer all by themselves. Whether your needs are for sealing applications in hot furnaces or gascutting systems, Huamei’s SiC bushings and seals bring unparalleled resistance to high temperatures in whatever extreme heat application you have. With a dependable sealing solution that adopts to high temperature and other demanding environments, Huamei enables industries to improve efficiency and security.

Advantages of SiC for Sealing Applications

Benefits of Huamei SiC Bushings and Seals are more than high temperature resistance. Silicon carbide is likewise recognized for its good chemical resistance, low friction coefficient and high wear resistance and is well suited for aggressive sealing applications. The long life time and less maintenance RBSiC/SiSiC components for heat treatment of Huamei SiC products helps users to save on their cost and get higher productivity. Furthermore, the high precision machining capabilities from Huamei guarantee close tolerances and uniform quality in each piece of SiC bushing and seal to provide superior performance and long life.

Keeping a hot lid on it with SiC tech

SILICON CARBIDE SIC BUSHINGS AND SEALS Huamei mechanical seal face materials are widely used in many different industries, including food and beverage processing, wastewater treatment plants, oil and gas refinery and distribution systems, nuclear power generation. The outstanding thermal stability of silicon carbide SSiC components for heat exchangers outperforms the temperatures well over 1000 °C which Huamei seals face to provide highly reliable sealing in extremely harsh industrial applications. When you select SiC bushings and seals from Huamei, you can count on the strength and dependability of your sealing solutions, minimizing potential downtime, leaks and expensive damages due to seal failures. With Huamei’s leading SiC technology, industries can work Silicon carbide (SiC) heat exchanger tubes/pipes with peace of mind at high temperatures so they can see that their seals really and truly stand up to the heat.

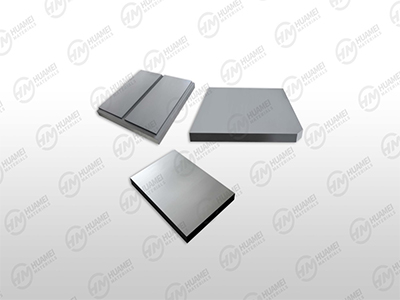

For structural and shielding applications, SiC sheets or tiles are one of the candidate materials due to their high strength and hardness. At Huamei, we offer customers a wide selection of quality SiC and other products for various applications. Structual Inprovements to High Temp Protection and Beyond: SiC-sic Plate & Tile.

The greater strength of SiC sheets for structural applications

The high strength and wear resistance of SiC layers for structural use is one of the main advantageous medical manufacturers. SiC (silicon carbide) is a high-performance ceramic material, which can retain its excellent properties at elevated temperature and under severe conditions. Carbon/SiC sheets provide unparalleled strength for those manufacturing building structures, equipment bodies or machinery components and have the durability to last. Innovative production methods used by Huamei guarantee that our SiC wafter product meets the quality and reliability levels your specific application demands.

SiC tiles and ultimate heat protection

SiC tiles are known to offer the maximum protection against high temperature. So whether they are in furnaces, kilns or thermal processing machinery, the SiC tiles could bear how temperatures that cause other substances to breakdown. The advantages of SiC, such as its high thermal conductivity and resistance to thermal shock, make it attractive candidate for application at high temperature. At Huamei, we remain committed to providing top-notch protection with our SiC tiles to assist in keeping industrial processes safe and productive.

The protective application potential of SiC sheets

SiC has also been considered for protective applications because of its multiple functionalities. SiC sheets have a broad spectrum of protective applications, from lining materials for acid tanks to protecting mechanical components and metal parts. Their abrasion resistance, lack of chemical reactivity and nonflammability make them ideal for such applications. Our SiC sheets are engineered to offer dependable protection and extend the service life of machinery and facilities.

Light-weight and high- performance with SiC tiles

Besides their refractory properties, SiC tiles possess specific weight values that are lighter than other from the perspective of practicality options. Although being light weighted, the SiC tiles have very high strength and is able to take heavy loads and mechanical shock. It is this balance of long-term strength and lightweight properties that sets SiC tiles in a class all its own, suitable for tough weight-restricted applications ranging from aerospace components Silicon carbide (SiC) protective plates for slurry pumps to automotive hardware. At Huamei, we guarantee that the production of these SiC tiles is carried out in compliance with the set industry standards to serve varied needs of its customers.

Novel SiC sheets and tiles solutions for structural applications

Huamei SiC sheet and tile structures Furthermore, the SiC sheets and tiles offered by Huamei are significantly advancing the state of the art in structural as well as protection materials. If its increasing the Silicon carbide (SiC) bulletproof sheets/tiles tensile strength of a building, protecting equipment from high temperatures, or creating light weight highly durable parts… SiC products can do it. Based on our unique know-how and cutting-edge technology, we are constantly pushing the limit of what can be accomplished with SiC material, providing customers with products which both satisfy and exceed their expectations in terms of performance. Driven by Innovation and Performance, we are Shaping Today’s SiC lass_2 For more information on Represents typical value for this property/grade.

For manufacturing ultra-hard materials and effective shielding technology, boron carbide is a versatile, yet extremely light, material. Nanomaterials with narrow size distributions of boron carbide have many woven applications such as military armor and radiation protection owing to the unique properties of boron carbide. Shandong Huamei,as one of leading RBSIC/SISIC manufacurers with German technology. Leveraging on innovation and quality, Huamei offers a wide range of industrial products.

Boron Carbide-In Ultra-Hard Materials A particle or fiber reinforced composite or a single phase material consisting of boron carbide Powder Metallurgy-The sinusoidal behavior is explained.

Given the superior hardness and wear resistance of boron carbide, it is a preferred material for preparation of ultra-hard materials. It is widely used in armor plating and bullet proof paneling as it is capable of withstanding the impact of high-velocity bullets. Boron carbide is used in the production of knives for cutting and shaping, and it also cuts metal swiftly; making bullets that can penetrate armor.

Improving Shielding with Boron Carbide

Outside of hard materials, boron carbide is used in the nuclear industry to improve shielding capabilities and provides for greater protection against types of radiation. At the same time, boron carbide shields are widely utilized in nuclear reactors, nuclear waste storage sites and medical diagnostics aiming to reduce the negative impact of radiation. It is by the way that the high-neutron absorbing features of boron-carbide have led to its use as a radiation shield, offering protection against dangerous radiation for people working in hazardous zones.

Advances in Armor Technology with Boron Carbide

As an armor technology staple, boron carbide is used in kevlar vests (military/police) and many composites and advanced wearable sporting equipment. Contemporary armor is bullet-resistant with the addition of boron carbide in order to make body armour, vessel armour, and car armour plates of any thickness. Huamei's advanced ceramics technology utilized to develop breakthrough armor solutions for defense and security applications.

Boron Carbide in Military and Defense Applications

The military and defense industries utilize boron carbide as it has superior properties and performance characteristics. Its applications range from vehicle Silicon carbide carborundum powder for silicon carbon rods hardrives to aircraft parts, where it's used to improve the lifespan and safety of important materials and personnel. Boron Carbide, with its high hardness of over 9 MOH and low density is a tubical choice for military coat use; making it the world's third hardest material and the densest compound "think tank" (aka intense sandbag).

Boron Carbide for Radiation Shielding Applications

Radiation shielding is essential for applications in Boron carbide (B4C) mircro powder several industries, such as health care, nuclear power production and aerospace. By virtue of the fact that boron carbide absorbs neutrons as well as gamma rays, it is useful as a radiation shield. Using boron carbide shields in equipment and structures can greatly minimize the dangers associated with exposure to radiation, protecting people as well as delicate instruments from harm.

the ductility and efficiency of boron carbide in ultra hard materials & armour as well as with the nuclear industry. With a strong focus on innovation and quality, Shandong Huamei makes advanced boron carbide products widely B series boron carbide (B4C) mircro powder accessible to support different industries’ changing requirements. As a innovator in the advanced materials industry, Huamei’s innovative boron carbide applications push performance and reliability to new levels for industrial manufacturing.

Know the advantages of SiC lining that protects from corrosion

Though it has long plagued industry, corrosion can be a... When metal parts are exposed to corrosive agents such as chemicals or moisture, they may wear out faster over time which can result in equipment malfunction and expensive rehabilitation. Here’s where SiC protective coatings come in.

Parameter of primary significance for the selection of SiC liners for Most corrosion resistance

Here are some key factors to consider when choosing SiC linings for your industrial machinery and equipment. First, you have the corrosive air in which the equipment operates. Temperature, pressure, the corrosive media type will influence how well a protective lining works.

SiC lining protection for industrial machinery/extended life_predictions

One of the key benefits to utilizing SiC protective linings is its ability to substantially prolong the life expectancy of industrial hardware. SiC linings frequently stop metal wear and breakdown by providing a long-lasting inert barrier between the corroding environment and key internal equipment surfaces, reducing or eliminating the need for expensive repairs and replacements that incur costly downtime.

IN DEPTH: UNLIMITED MATERIAL How SiC protects against corrosion better than titanium or PTFE

Metallic materials like stainless steel and rubber linings had been used previously for corrosion resistance, however SiC has benefits that distinguish it from other types of protective linings. SiC linings offer the best level of corrosion protection and highest thermal conductivity, plus a level of wear resistance such that it is appropriate for rough industrial use. Also, these light SiC linings are easy to put in place and to repair/install themselves although if they are hard materials than the conventional materialization.

Installation & Maintenance Tips for SiC Protective Linings to Extend the Life of Your Structure with Maximum Corrosion Resistance

Correct design and installation of SiC lined protection are important to guarantee that industrial equipment is fully protected against corrosive attack, prolonging its life. It’s important to follow the manufacturer instructions and suggestions when it comes to installation of SiC liners — this will help Silicon carbide (SiC) protective plates for slurry pumps ensure a good fit and provide maximum protection. Regular maintenance and routine checks should also be performed to find and prevent any problems before they turn into expensive repairs. Companies in industry can optimize corrosion resistance and preserve valuable systems for the long-term by taking a preventive approach through the installation and upkeep of SiC protective linings.

These SiC protective linings from Huamei represent a treat for the prevention of corrosive wear to equipment and facilities at an extremely low cost. Through a greater understanding of the advantages offered by SiC linings, and through the consideration of key selection factors and proper installation and maintenance practices for these materials, companies Silicon carbide (Sic) thermocouples protection tubes/pipes can protect their assets against corrosion damage. HUAMEI is pleased to do that, with HUAMEI's advanced technology and experience on RBSIC/SISIC ceramics, industry can rely for durability combined with cost effectively performance of SiC protective linings to safeguard their valuable assets and ensure smooth operations.