Blogs

A guide on starting an indoor playground business If you love kids and want to provide a safe, fun place for your children — and others' too-consider starting an indoor playground business. If you are planning to launch your own indoor playground business of America, there are some things that must be considered and taken care in order to get started on the right footing.

Well, for one you will need to research and assess the demand of indoor playground equipment in your area. Take a look around for existing indoor playgrounds in the area, and judge their popularity with families. When you’re organizing your ideas, it can help to speak with parents in your area and ask them what they would like from an indoor playground. This experiment will give you an insight into what your customers want and modify your business to meet that demand.

Then, sketch a preview of your target market, revenue sources, and marketing tactic. Children with your target market is families with young children so try and provide a range of different types of play equipment and activities to suit kids across all the ages. Consider how you will make money, whether it’s by charging admission, booking parties or selling concessions. Create a marketing plan to meet your target audience, through social media campaigns, local advertisements or partnerships with daycare facilities or schools.

For your indoor playground business funding, consider taking out a loan or grant, or finding investors. You might need money to rent a space, buy equipment and pay employees while your business becomes profitable. Think about financing from banks, government programs or individuals who believe in your business concept.

The right spot for your children’s indoor play area is everything. Find a location that can be easily accessed by families and has the amenities, such as restrooms, parking and general safety, is necessary for operating an indoor commercial playground . Think about the space itself and how it can be divided up to different play areas, seating for parents and a snack bar or café. When designing and organizing the space, consider aesthetics to foster a fun and friendly environment for kids and parents.

Before you can open your indoor playground, ensure that all standards for running this type of establishment are met. This includes acquiring all necessary permits or licenses, respecting safety equipment protocols and establishing health and sanitation measures. A safe and fun play space where kids can really be kids is the most important consideration!

Finally, I hope it can help you start an amusement park business, hope you love children and work in this place! Research demand in your area, define the target market and revenue streams, secure finances, select a location and complying to safety standards and regulations can position you for success in the indoor playground equipment industry. With dedication, imagination and a concentration on the spreading happiness of children and a place where families can enjoy time together your indoor play park business will flourish into a favourite part of your community.

Nobody really likes a good old block of ice. It is just called “ice” because that’s the name it was given (kind of like Mike, only not nearly as sweet). Our company, Icemedal would love to ensure that anyone is able to have good ice at all times. That’s why we have automated ice-making factories to assist us in making ice fast and efficiently. However, however, these factories need to be looked after just like any other machine if production is going to continue trouble-free: in today’s post we’ll find out how to make our minimum-attention ice factories more worry free!

Carrying out routine maintenance checks for best results

Regular maintenance checks are analogous to taking a trip to the doctor for a check-up. It allows us to look in and see if everything is running smoothly, or if something needs to be fixed. In our automatic ice making factory it is necessary to make thorough maintenance inspection, in order that all parts may be in proper operation. This will help to avoid any major issues occurring later. So our Icemedal team ensures reoccurring maintenance visits for our factories so we can run perfectly.

Investing in better gear for less risk.

When we purchase things, some of what we seek that it be good so it is durable. The same is true for our automated ice-making factories. When you invest in that kind of equipment, we are getting machines that are heavy duty and reliable.” This can also help avoid breakdowns or other issues that could cause us to slow down our ice output. At Icemedal, we ensure that we only invest in the highest-quality machinery for our factories so that we can continue to make shitloads of tasty ice without ever having to worry.

Use of automatic alerts for early diagnosis and prompt intervention

Occasionally, our automatic ice-making facilities may encounter situations that we hadn’t anticipated. To assist us in identifying and resolving these issues when they occur, we have added automated alerts. These alarms give us a voice to tell if our ice making factory are going bad so we can act immediately. This should go a long way toward stopping any bad problems from occurring and keeping us on course with our ice production. At Icemedal we are vigilant about these alerts and resolve any issues immediately.

Educating staff how to operate and maintain it properly

Like learning to ride a bike, or swimming, we need some training, too in how to operate and maintain automated ice-making factories. At Icemedal you can always train your staff on how to operate the machines correctly and be able to maintain them. This will also avoid accidents or errors that may lead to interference with our ice production. By ensuring that our staff are trained, we can ensure problem-free operation of factories.

Having a standby system to avoid down time on breakdowns.

Even with all the love and TLC we pour into our automated ice-making factories, things can go wrong. Which is why we have backup systems. We’re like having a spare tire, in case we have a flat. They are there to help us make ice in case one of our main machines breaks. Icemedal we ensure such measures are in place and when all of the other systems fail, we keep the power running to prevent downtime for our ice generation.

In short, reducing the amount of concerns at our automated ice making factory matter to us so that we can continue dispensing delicious slabs for all. Through routine preventative maintenance, proper purchase of quality tools and supplies, automatically activated warnings through computer systems monitoring the condition of the machinery, staffed properly trained personnel to not only operate but assess breakdown and options in resolving them - we can keep our plants operating at top efficiency. So, when you indulge in an icy treat from Icemedal, remember that worrying less is how our worry-free factories get things done.

Selecting a good commercial flake ice machine is certainly an important decision for any company that requires ice as part of department operations. We know that people need a machine that can suit their needs and provide them with reliable ice production here at Ice medal So, today we will talk about how you should choose the best flake ice machine possible – one that is not only effective but is durable and cost efficient as well.

Appreciating the Significance of Flake Ice Quality

The quality of flake ice that a machine makes is important for establishments like seafood markets, restaurants and even hospitals. Flake ice is soft and easy to mold, so it's perfect for keeping perishables fresh while displaying them efficiently. Another factor to consider when selecting a flake ice machine is the quality of the ice it produces. for machines that’ll produce consistent and clean flake ice, without impurities. Ice medal take the quality of the ice our machines produce seriously ensuring that it is of the highest standard for all our customers.

Capacity And Production Rate Assessment

It is also important to consider the capacity and production capability of a flake ice machine. Businesses have different ice requirements, and therefore it’s crucial that you identify a machine that will be able to meet your demand. Check the daily ice making capacity of the appliance and compare it to your needs. Also, take into account the production rate per hour to see how fast the machine can produce ice. Flake Ice Machine Halo Ice medal offers flake ice machines in a variety of sizes to meet your needs.

Yes, one can invest on the Durability and the Longevity of the Machine

Purchasing a high-quality flake ice machine is an important decision, thus we need to take into account the lifespan of the machine. Find machines that are constructed with durable materials and have a history of long-term use. Remember to check the warranty and after-sales service provided by the manufacturer so that your investment is safeguarded. Icemedal is devoted to the durable and stable ice flake machine that runs for a long lifespan.

Weighing in on Energy Efficiency and Maintenance Costs

Energy efficiency Energy efficiency is also an important thing to look at before buying a flake ice machine . Search for energy-saving machines that will help control power consumption and pollution. Take into account the power use of this machine and compare it to other models to seek out essentially the most value-effective model. In the community (39) Founded by Icemedal You May Have Heard About About Us Icemedal makes energy efficient flake ice machines which will slash your running costs while still delivering you consistent& dependable flake ice.

The Battle of the Features and Technology for the Best Value

When selecting a premium flake ice maker, there are key technologies and features which make the ice that remove some models from others. How To Choose a Nugget Ice Maker When selecting a nugget ice machine, consider an equipment with high-end features such as automatic dispensers and self-cleaning modules. Don’t forget to look at technology in the machine you have selected so it doesn’t become obsolete and can cater for business needs. Icemedal provides the latest series state-of-the-art self-contained flake ice machines with great economy and reliability for Your best success.

To sum up, the importance of selecting a good flake ice machine is indispensable for those businesses where they depend on ice. Here at Icemedal, we appreciate the investment a quality and efficient machine is to you. You can pick out the right flake ice maker for your business, by taking these aspects into consideration like ice quality, capacity, durability and features to be energy efficient. Relay on the Icemedal flake ice machine for all your needs and enjoy our top-of-the-line products as well as friendly customers' service.

We all love ice – A delicious treat, especially on warm summer days. Ever wonder how ice is made? One clever way to make ice is with an automatic edible-ice factory. What in the world is an automatic edible ice factory, and how does it work?

An automatic Ice factory is a special place in which ice is manufactured with the help of machines and mechanisms. These factories are essentially magical ice-making machines, able to churn out plenty of ice in short order. They are automated, so robots and computers do most of the work. This speeds up the process and helps assure its accuracy.

How ice makers are being automated turning the industry on it’s head

Automation is reshaping the ice-making process. Thru the years ice was produced by hand which took awhile and physical work. But the ease of automated edible ice factories is another matter. What they can do is freeze the water, use cutting blades to shave the ice into cubes and package it for sale. This means less time and money is spent, resulting in more efficient ice production.

Advantages of automatic edible ice production factory

For those people who are seeking rewards like we have discussed. There are numerous advantages to using an automatic edible ice factory . One major advantage is that it’s capable of making ice much more quickly than traditional methods. That means the more ice in less time. Machines make ice more uniformly in size and shape than humans can, a distinction that matters for something like drinks or the preservation of food.

Another advantage of automatic edible ice factory is that it can work 24 hours,7days without stop. That is, ice can be made and shipped to stores and restaurants just in time. It’s perfect for businesses that need ice for temperature control.

The automatic course of the simmering down and freezing water to an edible ice

You begin, as does the process of manufacturing automatic edible ice factory , with water. The water is filtered to remove impurities and then frozen into ice. Then the ice is cut into cubes or other shapes with special machines. The ice is sorted and bagged for delivery to stores and restaurants.

Computers and robots manage the whole process, overseeing things so it all runs smoothly. They watch for temperature, ice quality and packaging. This helps make sure the ice is safe to consume and top-grade quality.

Automated systems for making edible ice, to maintain quality and efficiency

Automated plants for the production of edible ice are good at quality and productivity. The devices are constructed to produce ice in a manner which is both safe and sanitary. They are also programmed for stringent quality control, so you can feel confident that the ice you purchase is clean and tasty.

And automation in factories could help slash waste and conserve energy. It’s environmentally beneficial, and it keeps costs down. And it also means that more ice can be produced, which is crucial on hot summer days when demand is high.

In short, automatic edible ice factory are revolutionizing the making of ice. They apply technology and automation to make ice fast, safely, and with attention to quality. These factories are working hard to revolutionize ice manufacturing, so that we can all have our favorite chilled foods and beverages on command. So the next time you make it to sipping a glass of ice-cold lemonade, reflect on the epic journey your cube made to get there and thank an automatic edible ice factory like Ice medal.

Ever think about how roller shapes can have an oversize effect on how things move along a conveyor belt? They specialize in V-return rollers and other non-standard idler types for conveyor systems.

What is the V-return roller used for in conveyor system

V- Return roller re like the good guys of conveyor components. They are essential from carrying material from one location to another but also helps in returning the traveling conveyor belt back to its normal speed or location. V-Shaped roller pairs are great for guiding belts to a path that is off centre. That not only prevents it from gumming up the works, but also makes things last longer by decreasing wear and tear on the belt.

Advantages of using custom idler shapes for smoother material delivery

There are numerous benefits to conveyor systems when you integrate specific idler configurations and shapes, such as V-return rollers. Among the benefits are ease of material handling. And when materials flow along the conveyor belt properly, there is less likelihood of jams and delays in the production process. It's ultimately more productive and-efficient in the end.

Studying different V-return roller designs and applications

V-return rolls are available in a wide array of styles to accommodate different conveyor types and processing applications. Some have rubber rings orbiting the roller for added grip, some are constructed with sturdy steel to last. These versatile rollers can be used in a variety of applications across industries, from mining to construction to food processing and raw materials. When it comes to your needs, don’t let the use of V-return rollers disrupt production in any application.

Maximizing conveyor performance with the right idler shape

Choosing the Right Idler Shapes to Keep Your Conveyor Rolling To make sure a Return rollers for conveyors system doesn't stand still, you need some parts to keep things moving. By utilizing specifically designed V-return rollers and other good idl er shapes you can improve the performance of your conveyor system. This can mean less downtime, better productivity and lower long term maintenance costs. The right idler configurations can do wonders for the effectiveness of your conveyor system.

Special shaped idler to improve efficiency and less wear on conveyor system

Specialized idler shapes not only improve performance but also can provide an improvement in efficiency and a reduction in wear to the conveyor belt. Select the correct roller shape to straighten out the materials flowing along a belt and reduce or eliminate the wear caused by friction. This helps to prolong the working life of the conveyor belt and saves maintenance repairs and frequent changes. Right idler shapes ensure your conveyor belts also run smoothly for longer.

In summary, V- Return idler roller and such; other specialized idler shapes are an important component in conveyor systems which serve to help control the tracking of a belt as well as interface with a sealing whole cleaning system. By increasing your knowledge of the contribution made by these rollers, looking into them and finding out about different models used and when they are in use and increasing its efficiency, you will actually save on wear and tears over the long run. So the next time you're watching a conveyor belt in action, don't underestimate the engineering finesse of V-return rollers and other specially shaped idlers that help everything juggle along with yourself.

The precision-ground conveyor idler roller we make is of good price and quality. These rollers may look like an ordinary roller, but they are critical to maintaining belt tracking in many types of industries. Today, we're going to introduce you to the ins and outs of how these critical parts are made, walking you through our production process so that you can see for yourself exactly what we do at every stage.

A closer look to the precision-ground conveyor idler roller manufacturing process:

First off all, we begin with choosing excellent materials for our idler rollers. We select the perfect materials that will last and leave a long lasting impression. Once our materials are on hand, we begin cutting. Our experienced workers utilize precision tools to accurately shape and cut the materials for each idler roller.

We now proceed to the grinding. “Magic happens here,’’ said Crosby. All our rollers are ground to perfection using the latest grinding technology. It is this meticulous grinding that makes our Impact idler roller stand out above the rest. We put the final touches and quality control is completed, once it has been grinded.

How we maintain quality in our manufacturing:

We check to ensure quality and that your part will be of the highest quality. We have a team of quality inspectors which checks the entire range idler rollers for any defects in functioning. Any rollers that don’t pass inspection are returned back for rework until they meet our high standards for quality.

Here’s how we perform our magic with precision-ground conveyor idler rollers:

The magic in our precision–ground conveyor Idler roller types is that we hit that sweet spot between accuracy and value. The finest raw materials are sourced, and our grinding machines employ the latest technology to produce products that are round and smooth. This precision from our workshop is what makes our rollers second to none.

How we do our best to provide a sustainable manufacturing process:

At MineAlpine, sustainability is our priority. That’s why we place an emphasis on sustainable production practices in our work. We operate energy-saving machines and also perform recycling program to waste down. When you choose us, you can rest easy knowing that your support is going to a company that cares about the environment.

Let us introduce you to the high-quality production of our precision-ground conveyor idler roller process dedicated to being the best in business:

Quality is at the heart of everything we do with MineAlpine. It’s our passion for quality that keeps us up to 3am making the best idlers in the world. We are proud of our product, and back every roller that has our name on it.

In summary, here at MineAlpine we are very proud of not only to provide precision-ground Idler conveyor roller that last long but also be efficient and good for the environment. Our production system is painstakingly crafted in our factory to make sure your candle is gorgeous from start to finish, from choosing the vessel to the final quality check. From the moment you choose MineAlpine, yours in quality and sustainability. Thank you for giving our manufacturing process a close look - we can't wait to provide you with the greatest idler rollers available anywhere.

The Significance of Custom Conveyor Rollers

Conveyor rollers are the wheels of a car and to transport items, they need to work beautifully and quickly. Conveyor Rollers for Smooth Material Handling Nothing beats the quality and quantity of products you'll find in our huge selection of conveyor rollers. But sometimes regular conveyor rollers are just not good enough. This is where custom conveyor rollers are useful!

When You Need Conveyor Rollers That Meet the Demands of Your Operation

Try walking around in shoes that are several sizes too small or large for you. Walking would be both uncomfortable and hard. The same is true for Plastic conveyor rollers . When the rollers aren’t the proper size or shape for a job, it can lead to problems such as items slipping through spaces or failing to move at all. Custom conveyor rollers are built to suit your individual requirements, so everything is just perfect.

Optimising Factory Production with Custom Conveyor Rollers One of the major benefits of a customised roller is that it can help increase your manufacturing efficiency and productivity.

Efficiency is about doing things as quickly and effectively as possible. Custom Rollers And Their Benefits To Conveyor Systems When it comes to conveyor systems, being able to utilise custom rollers can play a huge role in maximising efficiency and performance. With the appropriate size and type of rollers to reduce downtime also have been successfully employed where inlet feed chute exits into a storage bin to keep the bins filled. Now, with custom conveyor rollers from MineAlpine, there's no hiccup to getting things moving.

Benefits of using non-standard Conveyor Roller Sizes

While buying non-standard Conveyor rollers for sale sizes might seems like a big decision it can be extremely advantageous to do so, and here’s why. Customised rollers are made according to your needs, that can lead to increased productivity and cost savings over time. By selecting the appropriate size and type of conveyor rollers, you can even help minimize maintenance and downtime allowing your production chain to work at top efficiency.

Custom Conveyor Rollers and How They Can Improve Efficiency

Efficiency is about making things work better and faster. Custom Conveyor Rollers The importance otherwise of Custom Conveyor Rollers As with some mining products, a conveyor system is only ever as good as the rollers that it uses to transport material. By operating with rollers customized for your operations, you can increase the speed and precision of product transport which can improve your throughput. Gain an edge over the competition Order your custom conveyor rollers from MineAlpine.

In summary, custom Pvc conveyor rollers can help ensure the right operation of virtually any conveyor system. Knowing what you’re doing and knowing how your specific requirements need to be met, you can get a wonderful ROI from custom conveyor rollers. So the next time that you need unconventional sizes of conveyor rollers look no further than MineAlpine who can supply to fit your custom needs.

Realise the Advantages of Aluminium ACP Panels for Your Construction Project

Why Choose Aluminium ACP SheetsAluminium ACP sheets have been used widely in construction and due to their high quality since they were introduced. Pufeier provides premium aluminium ACP panels that are ideal for any construction projects. These are strong yet lightweight sheets, which are simple and easy to install, with minimum maintenance required. They also come in various colours and finishes to give your building that personalised feel. Furthermore, aluminum ACP sheet can be bent or folded depending on what you would like to use it for. Whether you are working on a creating a home, retail space, building or automotive project, aluminium composite panels (ACP’s) from Pufeier are the ideal design source to enhance your building façade.

How to Find the Best Aluminium ACP Sheet Manufacturer for Your Bulk Requirement?

What to look for in your provider of Aluminium ACP sheets There are some key elements to take in consideration when choosing a supplier and make sure you’re getting the quality that is suitable for all of your wholesale needs: The first thing to consider is a manufacturer that has been well-recognized in the industry - such as Pufeier, they have high-quality products and offers great service. In addition, you should select a supplier with extensive color, finish and size options to fit your particular project needs. Also, one should look on the supplier's shipping times, costs and warranty terms to make sure that you will have your product with ease. With a distributor like Pufeier for your wholesale building projects, you can always be confident that you are receiving only the finest aluminum ACP panels.

Typical Applications of Aluminum ACP Sheets in Today’s Architectural and Design World

Aluminium ACP sheets are used for various purposes such as building facades, shop names or model name etc. nowadays aluminum ACP sheets are popularly being used for not only exterior but also interior use. They are available in shades of white, and 20 designer colors to provide a sleek and modern appearance on the buildings. Aluminium ACP sheets are also selected for their weather proofing capabilities, corrosion resistance and great thermal insulation properties. What’s more, these panels can be rolled and shaped to become a point of difference in architectural façade design, which is certainly desirable for modern and creative designs.

Keep up with the trends! …With Quality Aluminium ACP SHEETS!

Keeping Up With the Modern trends in architecture & Design: In order to keep up with modern trends, its imperative to always use high-end material when designing homes or business flamboyantness, such as aluminium ACP sheets Pufeier offer. Our Aluminium ACP sheet is created utilising aluminium acp sheet the latest technology and top-quality materials for durability and long life. Available in a broad variety of colors, gloss and thicknesses, our Aluminium ACP sheets can be designed to suit an endless array of designs and applications. Using Pufeier Aluminium ACP designers and architects are able to produce long lasting, deep spandrel building veneers at a relatively low cost for decades.

Why the Quality of Our Aluminium ACP Sheets Can’t Be Matched by Our Competitors

At Pufeier, we are committed to supplying superior ACP sheets at a price that everyone can afford. We ensure that our Aluminium ACP sheets and Aluminum Composite Panels are an excellent acp aluminium composite panel quality, if made with high-quality aluminium as well as a special coating process so that it remains weather-resistant, UV protected and fire resistant. Our sheets are also lightweight and very easy to work with allowing for an ability to install anything you can dream up! And with an emphasis on innovation and customer satisfaction, Pufeier Aluminium ACP sheets are the ideal material for DIY enthusiasts looking to acp aluminium create attractive building facades. Select Pufeier for your next project and you will see the difference aluminium ACP sheet makes to modern architecture and design.

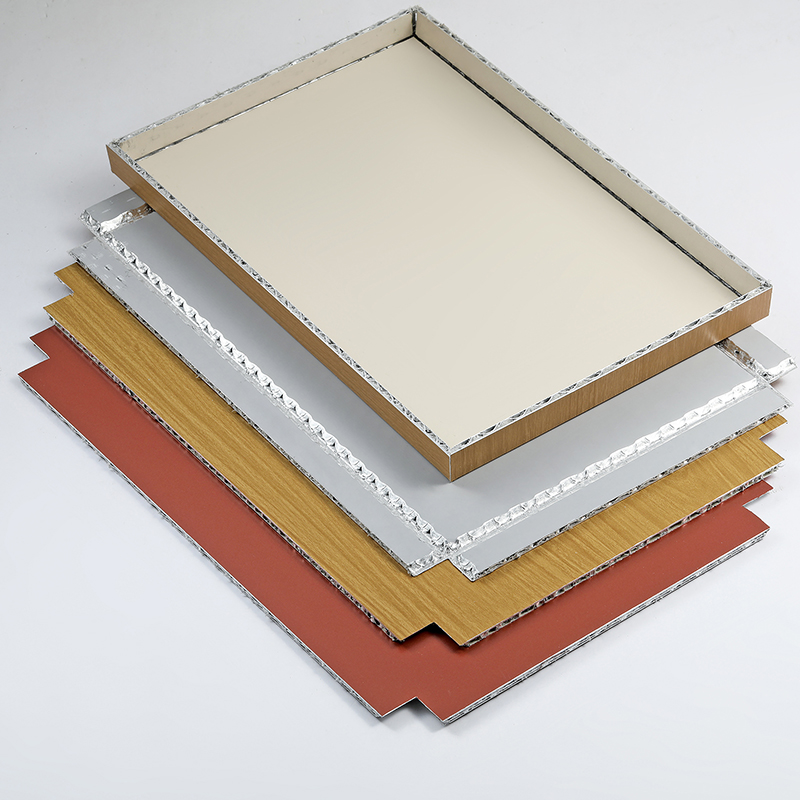

Do you need a trustworthy supplier for the custom aluminum honeycomb panels of your project? Look no further than Pufeier! We focus on producing quality panels for warehouse projects. Keep reading to discover what you need to know, and why our panels are the best solution for your next project.

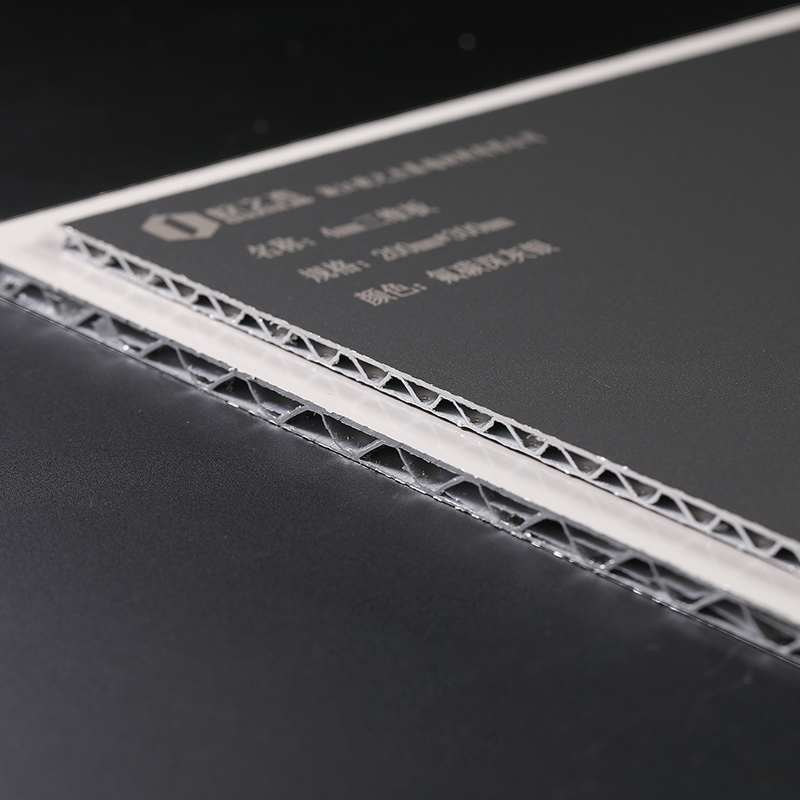

What you need to know

There are some important factors to consider when selecting a custom aluminum sandwich panel manufacturer; depending on your unique requirements, you won’t want to rush the decision or take it too lightly. First and foremost this means that the manufacturer has a good track record of making great product. At Pufeier, we have already many years of experience in the field and are renowned for our high quality. Our panels are handmade with the utmost care and attention to detail, they have been ISO certified and are executed according to the strictest norms.

Also, it is highly unlikely for you to discover a prospective manufacturer that would be able to provide you too many options depending on your specific requirements. Pufeier is customizable, you can select the size, color and finish for this product that best fits your project.Contracts, table leaves or luggage. No matter the size of your project, small or large renovation or commercial development, our panels are the product you need.

Customer service Another aspect to ponder is the customer support of the producer. Pufeier is committed to delivering customers with the finest quality products and services. Our experts are with you every step of the way to ensure that you fabricate the panel that best suits your needs. We are proud to be able to provide solutions porn not products and our friendly staff is on standby ready to answer any questions that you may have.

Custom Wholesale aluminum sandwich panel for wholesale projects with good price

Pufeier supply Aluminum Composite Plate quality custom aluminum sandwich panels, ideal for wholesale projects. Our panels are built to be strong, long lasting and lightweight making them an ideal product for a variety of applications. No matter if you are developing a construction project or working on a large commercial project, our panels have you covered.

Quality is one of the most significant advantages to selecting Pufeier for your custom aluminum composite panels. We only use the best materials and the newest production techniques, so that our panels meet even most demanding standards. That means you can rely on them to be durable, reliable, and long-lasting.

Besides from their quality, our bespoke aluminum sandwich panels are also extremely versatile. Choose from multiple sizes, colors and finishes to brighten up any space you wish. From a smooth, contemporary feel to beautiful weathered and aged methods that resemble old world hand-wiped finishes, using our panels can acp aluminium composite panel be customized with a finish of your choice.

Additionally, our panels are offered at wholesale prices and are an affordable option for your project. Buy your Panels from Pufeier and save your wallet, but at the same time not compromise on quality. With our competitive pricing and dedication to excellence we are the best option for all of your custom aluminum sandwich panel requirements.

The perfect business solution for you

Looking For professional custom aluminium sandwich panel supplier? Look no further than Pufeier! We focus on manufacture high quality aluminium sandwich panels for you to use. If you’re looking for panels for use in construction, signage or any other type of project, we have the solutions. With our knowledge and modern facilities we are able to offer you the ideal solution for your business.

Advantages of having aluminum sandwich panels in your projects

Aluminium sandwich panels: a number of advantages in your projects. They're as easy to manage as they are durable and long lasting. Aluminum is also an incredibly flexible material and can be personally aluminium composite panel tailored for whatever your needs of it. Utilising our custom made aluminium sandwich panels is one way that you can achieve a contemporary and modern appearance for your project, and at the same time deliver all of the low maintenance and simple installation wellbeing benefits. Trust Pufeier with all your quality panel needs to give the best final products that are going to cheer up people lives.

Common usage problems in using custom aluminum solvent sandwich panel

Types and Applications of Aluminium Sandwich Panel Despite the numerous advantages, you may experience a few common usage problems when using custom aluminium sandwich panels. The only thing you need to be cautious about is the possibility of damage on the way and during installation. These panels are pretty delicate and you don’t want any dents or scratches, as it would affect the looks and functioning of the unit. Furthermore, the edges of the panels must be well sealed to avoid any water seeping in, causing possibly later corrosion. Avoid these common usage problems by following appropriate handling and installation protocols, and you will create custom aluminium sandwich panels which offer both long-term beauty for all your projects.

Pufeier your custom aluminum sandwich panel manufacturer for all of your project needs. With our premium-quality panels and unparalleled attention to detail, we offer the ideal solution to take your projects over the top. You can trust Pufeier for stunning quality panels that will bring the best in beauty and durable performance to your creations.

Expert advice on how to install aluminium sandwich panels effectively

Best Practices for Installing Aluminum Sandwich Panels When it comes to installation of aluminum plate-based panels, ensuring the following common best practices can make things go a lot smoother and potentially faster. A key tip is making sure the surface you’re installing it on is clean and clear of any dust. This will assist in ensuring the panels stick well and you do not face any problems during installation. Also, using the correct tools for the job including a level and drill, can make sure the panels are installed straight and tight. Lastly, it is important to adhere to installation instructions provided by the manufacturer in order for panels to be installed as recommended.

Step by Step Process of Installing Aluminum Sandwich Panels

To get the installation process underway, determine the space where you will install the aluminium sandwich panels. This will enable you to work out how many more panels to purchase, and how they’ll fit together. Then be sure to prepare the surface by scrubbing it clean and making sure that it is dry and free of dust or debris. Now that your surface is prepared, start setting the panel using these steps:

To remove any bubbles, just start next to one corner of the panel and press it in place, then move along the rest of the panel and make sure to slide out any creases.

Check with a level to be sure the panel is straight and properly aligned.

Fasten the panel with screws or rivets, keeping in mind to follow spacing and placement recommendations given by the manufacturer.

Repeat the above for each of your other panels, but adjust to ensure the gap between panels is left as one laminate thick.

Once all the panels are installed, fill any crevices or seams between panels with a silicone gel to inhibit water penetration.

With this guide along with the expert advice from us here at Fusion Facades, you can get your aluminium sandwich panels up in no time! Good luck and don’t rush – a job well done is a job that will look good for the next many years.

Where to get the best wholesale deals for aluminium sandwich panels

Whether you are searching for the best price on aluminium sandwich panels, do not hesitate - come to Pufeier. Browse through our range of premium panels and you'll find the solution - all at wholesale prices. Whether you are a contractor or DIY enthusiast, the panels can make your work more successful. You can check our more stocks at website or mail me for the best purchase on wholesale package deals of aluminium sandwich panels.

Misconceptions while installing aluminium sandwich panels

While installing aluminium sandwich panels, there are a few of errors that you must absolutely avoid in order to achieve successful, and long lasting installations. One mistake that is often made is to not prep the surface well enough before installation. Just be sure to clean and prepare the surface acp aluminium composite panel really well for good panel adhesion. You’ll also want to make sure that you aren’t using the wrong tools or techniques when installing. Make sure to pay attention to any mounting instructions given in the packaging and use the proper hardware, sealers and tools if a tight leak-proof fit is important. Finally, be sure the edges of the panels are sealed and finished to keep out water.

Top manufacturers for high quality aluminium sandwich panels for sale at wholesale price

Looking for super suppliers of high quality aluminium composite acp aluminium panel sandwich akm800 only on Pufeier. Whether you will choose to use fiber honeycomb, plywood or plastic such qualities don't really matter as all these types of panels combined with our prices could give a hope that you can find the suitable option for your project. Our panels are constructed from high-quality materials and will continue looking great on your next project. Get in touch with us now to discover more on what we aluminium composite panel can supply and get the best deals on wholesale prices for aluminium sandwich panels.