@aselle

- Followers 0

- Following 0

- Updates 343

Dicyclohexylamine as a Catalyst in Polyurethane Foam Production

There are so many other things polyurethane foam is used for though! But did you realize dicyclohexylamine is critical to helping polyurethane foam get made? With assistance from the pros at FNAT, let’s understand how dicyclohexylamine helps enhance polyurethane foam.

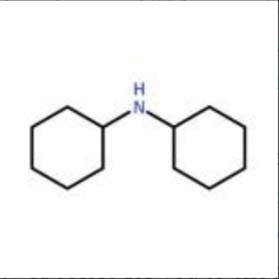

What is Dicyclohexylamine?

Something called dicyclohexylamine is a special ingredient, a sort of superhero in that it makes the polyurethane foam. A catalyst is anything that speeds up chemical reactions. When added to the mix of chemicals used to make polyurethane foam, coconut candle wax the reaction that causes the liquid to turn to foam. This is key, because it allows the foam to form faster and more evenly.

How Dicyclohexylamine Help in it?

With dicyclohexylamine as a catalyst, companies can produce more polyurethane foam faster. That would allow them to make more goods, such as mattresses and pillows, for those who need them. Dicyclohexylamine also contributes to making the foam stronger and longer-lasting, so products made of it will more effectively retain their shape.

Advantages of Dicyclohexylamine

Leather ProductionDicyclohexylamine use in producing polyurethane foam offers several advantages. It speeds up the foam-making process, soy coconut wax for companies. It also increases the quality of the foam so the products are more comfortable and durable. This is great for companies like FNAT, which enables them to deliver a better product to their customers.

Improving Foam Quality

Dicyclohexylamine is an important part of the recipe to make pure coconut wax great. This makes the foam stable and uniform, so there are fewer flaws or difficulties in the final product. This will be good news for consumers as products manufactured with dicyclohexylamine will have increased quality consistency.

The utility of dicyclohexylamine

“Dicyclohexylamine is the most efficient catalyst to make polyurethane foam,” experts at FNAT have determined. They determined that it can help hasten foam formation, keep costs down and enhance the quality over all of the foam. That makes the use of dicyclohexylamine an excellent choice for any company that is looking to create high-quality polyurethane foam products.

Conclusion

Finally, dicyclohexylamine is a key component in the preparation of polyurethane foam. It makes the foam stronger, more durable and faster to produce. Companies like FNAT rely on dicyclohexylamine to make safe, high-quality products and it is a product that customers trust and love. Learning about the way dicyclohexylamine is used to manufacture polyurethane foam gives us insight into the effort put into products we take for granted.